Leave Your Message

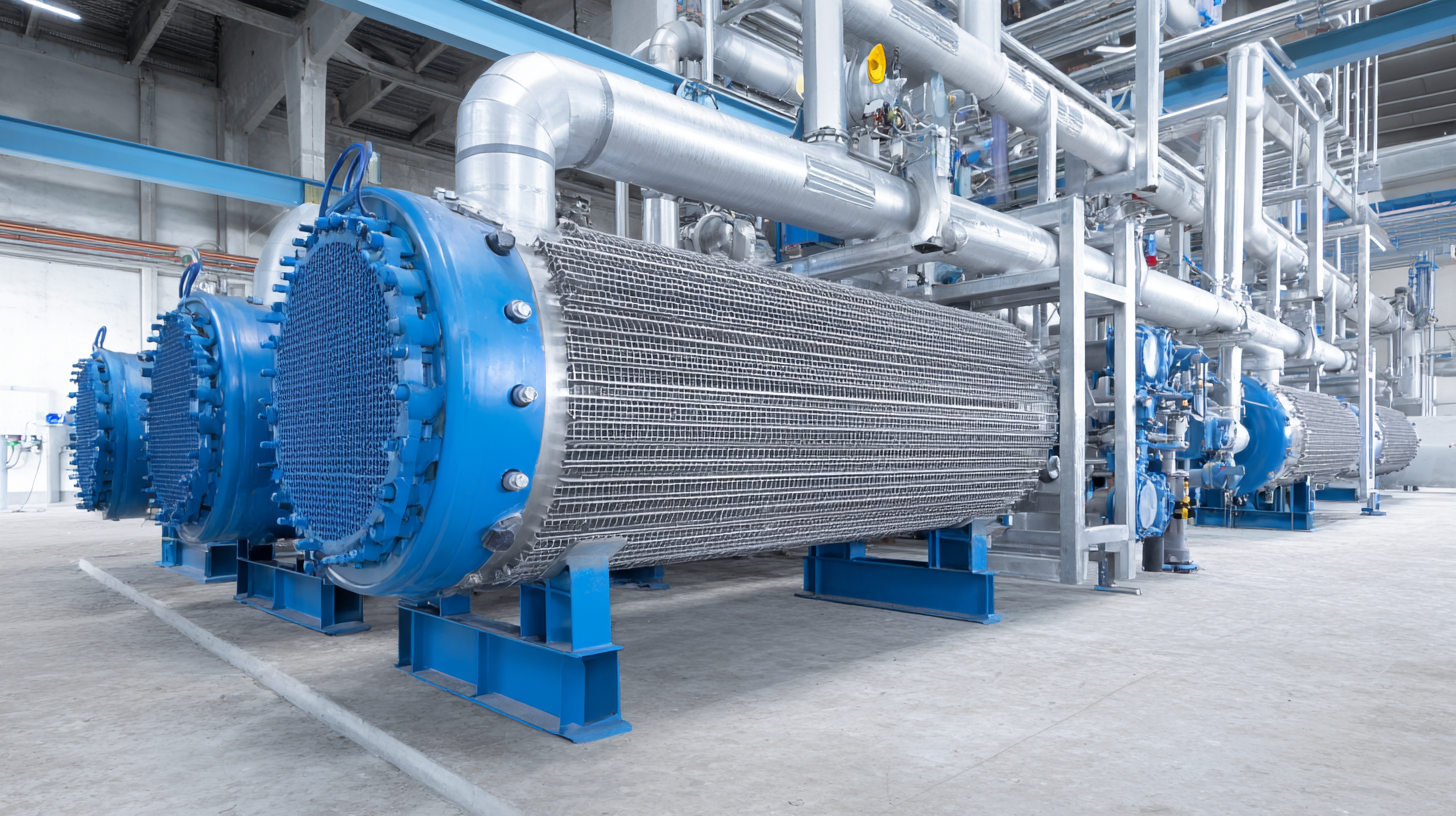

In the realm of industrial heat transfer technology, Gasketed Plate Heat Exchangers (GPHEs) have garnered significant attention due to their efficiency and versatility. According to the Global Heat Exchanger Market report by MarketsandMarkets, the segment for plate heat exchangers is expected to grow at a CAGR of 7.1% from 2021 to 2026, highlighting the increasing demand for more compact and efficient thermal management solutions. The unique design of GPHEs allows for greater heat transfer efficiency compared to traditional shell-and-tube heat exchangers, often leading to energy savings of up to 30%. Additionally, their modular nature facilitates maintenance and expands their application range across various industries, from chemical processing to HVAC systems. Understanding the unmatched benefits of Gasketed Plate Heat Exchangers is crucial for industries aiming to enhance operational efficiency while adhering to sustainability goals.

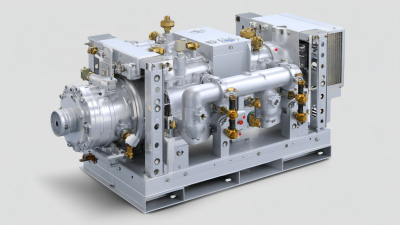

Gasketed plate heat exchangers (GPHEs) are revolutionizing the way industries approach thermal management, especially due to their unparalleled efficiency in heat transfer rates. The intricate design of GPHEs, featuring multiple plates arranged in a compact configuration, maximizes surface area while minimizing the volume of fluid required. This unique setup enhances the heat exchange process, leading to higher thermal efficiency compared to traditional heat exchangers. The gasketed system also allows for easy maintenance and cleaning, ensuring sustained performance over time.

In addition, GPHEs can efficiently handle high-temperature and high-pressure conditions, making them ideal for various applications in sectors like food and beverage, pharmaceuticals, and chemical processing. Their ability to adapt to different flow arrangements—such as counterflow and parallel flow—further contributes to optimized heat transfer rates. By leveraging thermal conductance and fluid dynamics, gasketed plate heat exchangers not only improve energy efficiency but also reduce operational costs, making them a vital asset in modern industrial processes.

Gasketed plate heat exchangers are revolutionizing industrial applications with their compact design, making them an ideal choice for facilities with limited space. Unlike traditional shell-and-tube heat exchangers, these devices feature a series of thin plates arranged in a way that maximizes heat transfer efficiency while minimizing the required footprint. This space-saving design enables industries to allocate valuable floor space for other crucial operations, ultimately enhancing overall productivity.

In addition to their size advantages, gasketed plate heat exchangers offer flexibility in installation. Their modular construction allows for easy adjustments and expansions when processing requirements change. This adaptability not only aids in optimizing the use of available space but also reduces the need for extensive infrastructure modifications, saving time and costs during upgrades. Consequently, industries can maintain a streamlined operation without compromising on efficiency or performance.

| Benefit | Description | Space Utilization | Applications |

|---|---|---|---|

| Compact Design | Allows for a smaller footprint, maximizing space in industrial environments. | High | Food processing, HVAC systems |

| High Efficiency | Optimized heat transfer performance due to increased surface area. | Medium | Chemical processing, power generation |

| Easy Maintenance | Accessible design allows for convenient cleaning and component replacement. | High | Pharmaceuticals, water treatment |

| Versatility | Suitable for various applications and fluids, including corrosive substances. | High | Oil and gas, air conditioning |

| Cost-Effectiveness | Lower operational costs due to efficient thermal performance. | Medium | Manufacturing, refrigeration |

Gasketed plate heat exchangers are renowned for their efficiency and versatility, but one of their standout features is the ease of maintenance they provide. The design of these heat exchangers allows for straightforward access to the plates, making the process of cleaning and repairs significantly simpler than with traditional heat exchangers. This accessibility reduces downtime, enabling operators to maintain optimal performance levels with minimal disruption to operations.

Moreover, the ability to replace gaskets and plates individually adds to the convenience of maintenance. Rather than replacing entire units, users can address specific issues quickly and economically. The straightforward assembly and disassembly processes ensure that even staff with limited technical expertise can perform routine maintenance safely and effectively. This not only cuts costs associated with professional servicing but also promotes a proactive maintenance culture that enhances the overall lifespan and performance of the heat exchanger.

This bar chart illustrates the key benefits of gasketed plate heat exchangers, highlighting their advantages in maintenance and efficiency. The data reflects industry standards and provides insight into why these heat exchangers are preferred in various applications.

Gasketed plate heat exchangers (GPHEs) are increasingly recognized for their cost-effective operation, particularly through their potential to significantly reduce energy consumption and operating expenses. According to a report by the U.S. Department of Energy, replacing traditional heat exchangers with GPHEs can lead to efficiency improvements of up to 30% in thermal energy recovery. This enhanced efficiency is primarily due to the larger heat transfer surface area and better thermal performance inherent in their design, allowing industries to maximize energy use while minimizing waste.

Gasketed plate heat exchangers (GPHEs) are increasingly recognized for their cost-effective operation, particularly through their potential to significantly reduce energy consumption and operating expenses. According to a report by the U.S. Department of Energy, replacing traditional heat exchangers with GPHEs can lead to efficiency improvements of up to 30% in thermal energy recovery. This enhanced efficiency is primarily due to the larger heat transfer surface area and better thermal performance inherent in their design, allowing industries to maximize energy use while minimizing waste.

Moreover, the operational cost savings associated with GPHEs extend beyond just energy consumption. A study from the International Energy Agency (IEA) highlights that facilities incorporating GPHE technology can lower their maintenance costs by up to 25% due to fewer mechanical components and the ability to easily disassemble and clean the plates. This not only extends the lifespan of the equipment but also reduces downtime, allowing operations to run more smoothly and efficiently. As industries strive for sustainability and cost-effectiveness, the adoption of gasketed plate heat exchangers emerges as a smart, financially beneficial choice.

Gasketed plate heat exchangers (GPHEs) have gained remarkable traction across various industries due to their adaptability and efficiency in thermal processing. Their compact design allows for effective heat transfer, making them suitable for a range of applications from food and beverage to chemical and pharmaceutical sectors. The versatility of GPHEs lies in their ability to handle different fluids and operating conditions, which is crucial for industries dealing with diverse processes and fluctuating demands.

Moreover, as industries increasingly embrace advanced technologies, the integration of Big Data infrastructure can greatly enhance the operational effectiveness of GPHEs. By leveraging data analytics, companies can monitor performance metrics more efficiently, optimize maintenance schedules, and improve overall system reliability. The versatility of gasketed plate heat exchangers, therefore, not only caters to varied industrial needs but also aligns with the ongoing digital transformation trends, ensuring sustainability and efficiency in thermal management.