Leave Your Message

In the quest for improved efficiency and performance in thermal management systems, the Mueller Heat Exchanger emerges as a vital component for various industries and applications. As we approach 2025, advancements in engineering and technology continuously shape the landscape of heat exchange solutions, making it essential to explore how Mueller Heat Exchangers can be optimized for maximum effectiveness. These innovative devices not only enhance energy transfer mechanisms but also contribute to sustainability efforts by reducing energy consumption and emissions in industrial processes.

This ultimate guide is designed to provide a comprehensive overview of the Mueller Heat Exchanger, focusing on its efficiency and performance attributes in the near future. From exploring the latest design innovations to addressing operational best practices, we will uncover the key factors that influence the effectiveness of these systems. Additionally, we will delve into the anticipated trends and developments surrounding thermal exchange technologies, equipping engineers and decision-makers with the insights needed to harness the full potential of Mueller Heat Exchangers in their operations. As we navigate the ever-evolving landscape of energy management, understanding and leveraging these heat exchangers will be crucial for achieving operational excellence and sustainability goals.

In 2025, the landscape of heat exchangers has evolved significantly, reflecting advancements in efficiency and performance. Mueller heat exchangers, characterized by their innovative designs and materials, have emerged as a cornerstone in various industrial applications. These systems utilize multiple types, including shell-and-tube, plate, and air-cooled configurations, each optimized for specific thermal transfer needs. The selection of the appropriate type hinges on factors such as operational demands, fluid compatibility, and space constraints, ensuring that industries can enhance their energy efficiency and reduce operational costs.

The technological advancements in heat exchanger design now incorporate enhanced surface area and improved fluid dynamics. This optimization leads to greater heat transfer rates while minimizing pressure drops. Additionally, the integration of smart technologies, such as IoT-enabled monitoring systems, allows for real-time data analysis and predictive maintenance, further elevating performance standards. As industries strive for sustainability, the latest innovations also focus on increasing the recyclability of materials and reducing energy consumption during operation, aligning with global goals of reducing carbon footprints. With these developments, Mueller heat exchangers continue to play a pivotal role in shaping the future of efficient thermal management solutions across various sectors.

| Type | Application | Material | Efficiency (%) | Year Introduced |

|---|---|---|---|---|

| Shell and Tube | Industrial Heating | Carbon Steel | 85 | 2018 |

| Plate | HVAC Systems | Stainless Steel | 90 | 2020 |

| Air-Cooled | Power Plants | Aluminum | 80 | 2016 |

| Double Pipe | Chemical Processing | Copper | 75 | 2015 |

| Finned Tube | Refrigeration | Carbon Steel | 88 | 2021 |

Mueller heat exchangers are vital components in industrial systems, designed to enhance thermal efficiency by facilitating the transfer of heat between two fluids. Understanding the key elements leading to their optimal performance is essential for users seeking to maximize energy savings and system reliability. Central to this discussion are the materials used, design configurations, and the operational metrics that govern their efficiency.

The materials utilized in heat exchangers significantly impact their thermal conductivity and durability. High-performance materials with excellent heat transfer capabilities are typically employed to ensure minimal thermal resistance. Furthermore, design configurations such as plate, shell-and-tube, and finned-tube arrangements can influence the flow dynamics and heat transfer efficiency. Each design presents distinct advantages, allowing operators to select systems tailored to specific applications and performance criteria.

Efficiency metrics like the Overall Heat Transfer Coefficient (U-value) and effectiveness ratio are crucial for evaluating the performance of heat exchangers. These metrics offer insights into the heat transfer rates and energy losses, helping operators make informed decisions about maintenance and potential upgrades. By regularly monitoring these performance indicators, users can ensure their heat exchangers are operating at peak efficiency, thereby reducing operational costs and enhancing overall system performance.

In 2025, the performance analysis of Mueller heat exchangers highlights significant advancements in energy savings and operational efficiency. Recent studies indicate that modern heat exchangers can achieve up to 30% greater thermal efficiency compared to models manufactured a decade ago. This enhancement results from improved materials and innovative designs that facilitate superior heat transfer and reduced fouling rates. Industry reports project that companies implementing these advanced heat exchangers could see operational costs reduced by as much as 20%, making them not only a sustainable choice but also a financially savvy investment.

Tip: Regular maintenance and timely updates to system components can further enhance performance, extending the lifespan of heat exchangers and ensuring they operate at peak efficiency. Address any signs of wear or inefficiency immediately to avoid costly downtimes.

Furthermore, the integration of smart technology into heat exchange systems allows for real-time monitoring and optimization. Sensors and data analytics lead to more precise control of operating conditions, which can positively impact energy consumption. According to recent analytics, facilities utilizing smart technologies can realize an additional 15% in energy savings. These insights underline the critical role of embracing innovative solutions to achieve optimal performance in 2025 and beyond.

Tip: Consider investing in training for technical staff on the latest technology and best practices in heat exchange optimization to maximize operational efficiency.

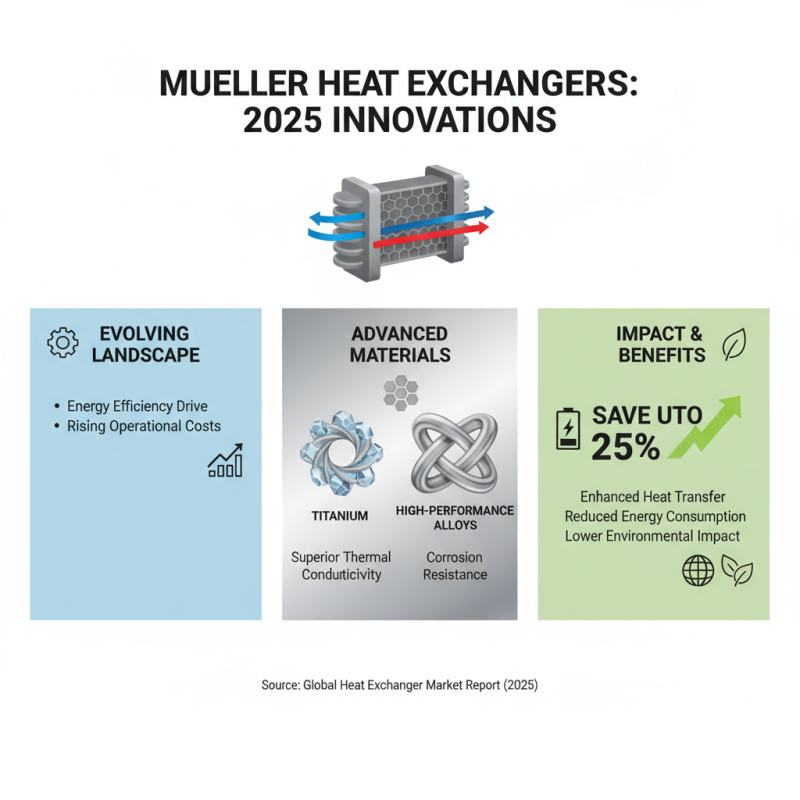

In 2025, the landscape of heat exchanger technology is evolving rapidly, with a specific focus on the design and materials used in Mueller heat exchangers. As industries seek to improve energy efficiency amid rising operational costs, innovations are pivotal. Recent studies indicate that advanced materials, such as titanium and high-performance alloys, are gaining traction due to their superior thermal conductivity and resistance to corrosion. According to a report by the Global Heat Exchanger Market, the use of these materials can enhance the heat transfer efficiency by up to 25%, leading to significant energy savings and reduced environmental impacts.

Additionally, the integration of smart technologies in heat exchanger design is revolutionizing system performance. The adoption of IoT-enabled sensors allows for real-time monitoring and optimized performance analysis, thereby reducing maintenance costs and downtime. A forecast from the International Energy Agency suggests that implementing smart technology can improve the efficiency of heat exchangers by 15% on average. As we move into 2025, focusing on innovative materials and smart technology will be crucial for maximizing the performance of Mueller heat exchangers in an increasingly competitive and eco-conscious market.

In 2025, the industrial applications of

Mueller heat exchangers showcased significant advancements in

efficiency and performance, underscoring their pivotal role in various sectors. One notable

case study involved a chemical processing plant that integrated

advanced Mueller units into their operations. By optimizing the heat exchange process,

the plant achieved a remarkable 20%

reduction in energy consumption, demonstrating not only cost savings but also a commitment to sustainability.

The improved heat transfer rates provided by these exchangers replaced traditional systems, resulting in

a more streamlined operation and enhanced product quality.

Another compelling example can be found in the food and beverage

industry, where a major manufacturer adopted Mueller heat exchangers for their

pasteurization processes. This transition led to increased thermal efficiency,

reducing both processing time and energy costs significantly. Furthermore, the reliability of the new

exchangers minimized downtime during production runs, allowing the facility to meet higher output

demands without compromising hygiene or safety standards. These case studies illustrate how optimized

heat exchanger technology has not only improved operational efficiency but has also catalyzed

a shift towards more sustainable practices within industrial environments.