Leave Your Message

In today's rapidly evolving energy landscape, the demand for efficient energy solutions has placed significant emphasis on the optimization of heat exchangers. A crucial component in various industrial processes, heat exchanger parts play an integral role in enhancing system performance and energy efficiency. As we move towards 2025, understanding the intricacies and advancements in these components becomes essential for engineers and industry professionals alike.

The right selection and maintenance of heat exchanger parts not only contribute to reduced operational costs but also support sustainability initiatives by minimizing energy consumption and waste. This guide aims to illuminate the most important aspects of heat exchanger parts, including materials, configurations, and emerging technologies that promise to revolutionize energy transfer processes. By delving into the specifics of these components, we can better appreciate their critical function in maximizing energy recovery and ensuring the reliability of thermal systems across various sectors.

As we prepare for a future that prioritizes efficiency and sustainability, staying informed about the latest innovations in heat exchanger parts will empower organizations to make informed decisions. This resource serves as a valuable tool for mastering the essentials of high-performance heat exchangers, guiding stakeholders towards more sustainable energy solutions in the years to come.

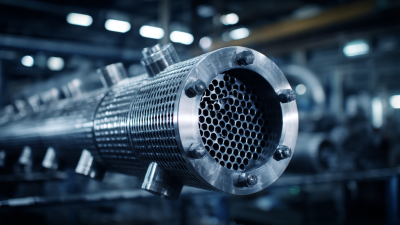

Heat exchangers are pivotal components in various industries, facilitating efficient energy transfer between two fluids. They come in several types, each designed to cater to specific applications and operational requirements. The most common types include shell-and-tube heat exchangers, plate heat exchangers, and air-cooled heat exchangers. Shell-and-tube heat exchangers are widely used in power plants and chemical processing, where high capacities and continuous operation are essential. Their design allows for robust thermal management and ease of maintenance, making them a staple in industrial settings.

On the other hand, plate heat exchangers are preferred in applications requiring compact designs and efficient heat transfer, such as HVAC systems and food processing. Their large surface area facilitates rapid heat exchange while minimizing fluid resistance. Finally, air-cooled heat exchangers are utilized in situations where water cooling is impractical, offering environmental benefits alongside operational efficiency. Each of these types is selected based on the specific thermal requirements, fluid properties, and space constraints of the application, underscoring the versatile nature of heat exchanger technology in achieving energy efficiency across diverse sectors.

Heat exchangers are essential components in various industries, responsible for transferring heat between two or more fluids. The effectiveness of a heat exchanger largely depends on its key components, which include the heat transfer surface, separator, and fluid channels. The heat transfer surface is designed to maximize the area for heat exchange while minimizing resistance to fluid flow. This balance is crucial to ensure optimal thermal efficiency and energy savings.

Additionally, separators play a vital role by keeping the fluids apart while facilitating heat transfer. They can be found in different designs, such as plate or fin types, each tailored to specific applications and performance requirements. Fluid channels, which direct the movement of liquids or gases through the heat exchanger, must be engineered to handle varying flow rates and pressures. The design of these channels can significantly influence the overall performance, helping to reduce energy consumption and enhance system reliability. Understanding the functions of these key components is critical for improving energy efficiency in heat exchanger systems.

| Component | Function | Material | Typical Application |

|---|---|---|---|

| Heat Transfer Plates | Facilitate the transfer of heat between two fluids | Stainless Steel | HVAC systems, refrigeration |

| Shell | Encases the heat exchange components | Carbon Steel | Industrial heating and cooling |

| Baffles | Direct fluid flow to optimize heat transfer | Plastic or Metal | Chemical processing |

| Gaskets | Provide sealing between components | Elastomer | Food processing, pharmaceuticals |

| Tubes | Transport fluids through the exchanger | Copper or Stainless Steel | Oil and gas, petrochemical |

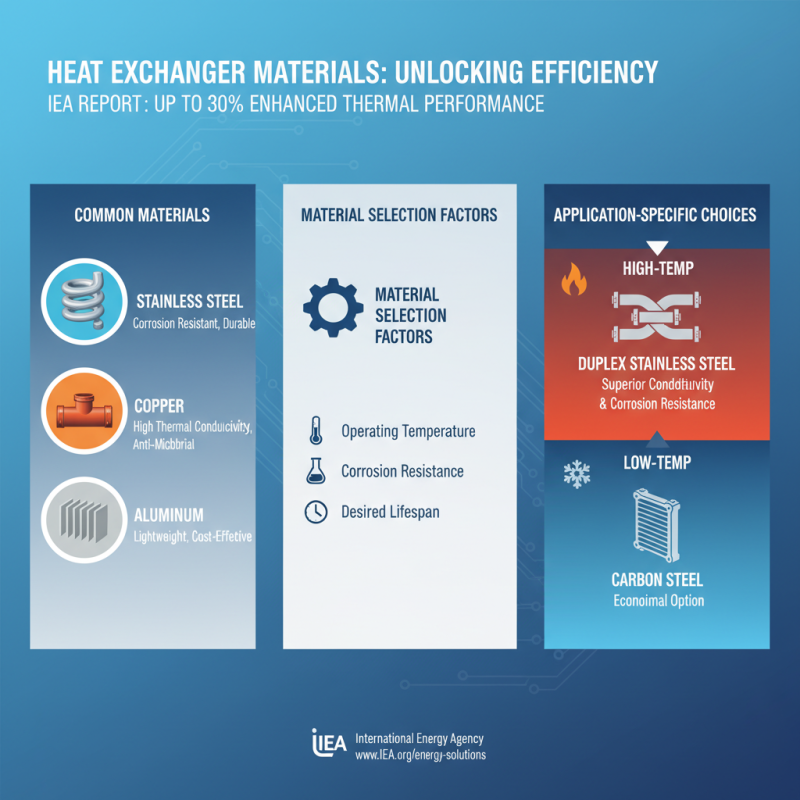

In the pursuit of efficient energy solutions, the material selection for heat exchangers plays a pivotal role in their performance and longevity. According to a recent report by the International Energy Agency (IEA), optimizing the materials used can enhance thermal performance by up to 30%. Commonly employed materials such as stainless steel, copper, and aluminum each offer unique advantages depending on the application, operating temperatures, and desired lifespan. For high-temperature applications, materials with superior thermal conductivity and corrosion resistance, like duplex stainless steel, are recommended, while lower temperatures may allow for more economical options such as carbon steel.

When designing heat exchangers, it’s crucial to consider not only thermal properties but also factors such as thermal expansion, fluid dynamics, and local environmental conditions. The choice of material should align with the specific operational requirements to mitigate issues like fouling and corrosion, which could otherwise lead to increased maintenance costs. The Heat Transfer Research Journal highlights that appropriate material selection can reduce these costs by nearly 25%, making it an essential consideration in the design phase.

**Tips:** Always conduct a thorough analysis of the operating environment and fluid characteristics to ensure optimal material selection. Consulting with industry experts can guide you in choosing materials that enhance efficiency and reduce the total cost of ownership. Additionally, consider utilizing advanced simulation tools to anticipate performance challenges linked to different material choices.

Maintaining heat exchangers is critical for optimizing energy efficiency and operational reliability. Regular maintenance practices, such as cleaning, inspection, and monitoring, can significantly prolong the lifespan of heat exchangers and enhance their performance. According to a report by the International Energy Agency, poorly maintained heat exchangers can lead to efficiency losses of up to 20%. Therefore, implementing systematic maintenance protocols is essential for any facility looking to maximize energy savings.

One effective maintenance tip is to conduct routine thermal performance tests to identify any deviations in performance. Such tests can pinpoint issues like fouling or scaling, which can adversely affect heat transfer efficiency. Additionally, ensuring that flow rates and temperature differentials are within optimal ranges can help maintain performance levels. Regular checks should also include visual inspections for

Another key practice is to schedule preventive maintenance during planned downtimes to avoid unplanned outages. This proactive approach not only minimizes the risk of mechanical failures but also supports consistent production levels. By monitoring operational data and utilizing predictive analytics, facilities can better anticipate maintenance needs, resulting in reduced costs and improved overall system efficiency. Integrating these practices into your maintenance strategy can lead to significant energy savings and enhanced operational sustainability.

As the demand for energy-efficient solutions continues to rise, advancements in heat exchanger technology are at the forefront of innovation in 2025. One prominent trend is the integration of advanced materials that enhance thermal conductivity and resistance to corrosion. These materials, such as titanium alloys and composites, not only improve performance but also extend the lifespan of heat exchangers in various applications, from industrial processes to HVAC systems. The focus on optimizing heat transfer efficiency is crucial in reducing energy consumption and operational costs.

Another significant trend is the adoption of digitalization through smart technologies. Implementing IoT (Internet of Things) capabilities allows for real-time monitoring and predictive maintenance of heat exchangers. Sensors can track performance metrics, enabling operators to identify potential failures before they occur, thus minimizing downtime. Additionally, data analytics can lead to improved designs tailored to specific operational environments, maximizing efficiency and effectiveness. As the industry moves forward, these innovations will play a pivotal role in transforming heat exchanger systems, driving them towards enhanced sustainability and reliability.