Leave Your Message

In recent years, the Phe Exchanger has gained attention for its unique benefits and applications. This innovative technology offers various advantages in multiple industries, making it essential to understand its potential. The Phe Exchanger is designed to efficiently manage and recover valuable materials, which can lead to more sustainable practices.

Many industries can benefit from the versatility of the Phe Exchanger. It plays a pivotal role in processes like waste treatment and resource recovery. With proper implementation, industries can reduce costs and environmental impact. However, it is crucial to acknowledge that not every application of the Phe Exchanger is flawless. Some processes may require careful adjustments and fine-tuning to maximize efficiency.

Understanding the top 10 benefits of the Phe Exchanger can provide clarity in its uses. These insights may inspire new approaches in various fields. It invites reflection on current practices and highlights areas for improvement. Exploring these benefits fosters innovation and sustainability in today’s rapidly changing landscape.

Phe exchangers play a crucial role in various industrial processes. They facilitate the transfer of heat between two fluids without mixing them. This function helps in maintaining energy efficiency in systems like power plants, chemical processing, and HVAC applications. Phe exchangers ensure that heat can be reclaimed and reused. This reduces waste and lowers operational costs.

These devices vary in design and size, tailored to specific needs. Plate, shell-and-tube, and air-cooled are common configurations. Each type has its advantages and drawbacks. For example, plate exchangers are compact and efficient. However, they may not handle high-pressure applications as well as shell-and-tube models. It’s essential to analyze the requirements before choosing the right type.

Understanding how these exchangers operate can reveal opportunities for improvement. Regular maintenance is vital to sustain performance. Neglecting this can lead to fouling, which reduces efficiency. Reflecting on best practices can help industries maximize their benefits. Proper training and awareness about these devices may prevent costly errors.

Phe exchangers are essential tools in various industries. They play a key role in improving energy efficiency. In power plants, these devices transfer heat from one fluid to another. This process helps optimize the use of resources. Industries leveraging phe exchangers often notice a reduction in operational costs. Fewer resources are wasted, leading to a more sustainable approach.

Moreover, in the food and beverage sector, phe exchangers ensure safe and efficient heating processes. They help in pasteurization and sterilization, protecting product quality. However, these systems can sometimes be difficult to maintain. Fouling can occur, reducing efficiency over time. Regular monitoring is crucial to overcome this challenge.

In the chemical industry, phe exchangers promote effective heat management. They assist in processes like distillation and evaporation. This maximizes productivity and minimizes energy consumption. Yet, installation can be complex. Engineers must carefully consider system design to avoid potential inefficiencies. Understanding these details can significantly enhance the overall performance of operations.

| Benefit | Description | Applications |

|---|---|---|

| Energy Efficiency | Phe exchangers utilize waste heat, improving overall system efficiency. | Manufacturing, HVAC systems |

| Cost Savings | Reduced energy costs by recycling heat, lowering operational expenses. | Industrial processes, district heating |

| Reduced Emissions | Minimizes greenhouse gas emissions by enhancing thermal efficiency. | Power generation, chemical processing |

| Versatility | Can be implemented in various systems across numerous sectors. | Food processing, oil & gas |

| Space Saving | Compact designs that fit into smaller installations effectively. | Building retrofit, small plants |

| Improved Process Control | Enhances system responsiveness and control over temperature variations. | Pharmaceuticals, HVAC |

| Enhanced Safety | Reduces risks of thermal stress and system failures. | Petrochemicals, food industries |

| Long Service Life | Designed for durability and resistance to corrosion and fouling. | Water treatment, power plants |

| Scalability | Easy to scale up or down as needed for changing process requirements. | Manufacturing, energy systems |

| Maintenance Friendly | Designed to allow easy access for routine maintenance and cleaning. | General industrial applications |

Phe exchangers play a crucial role in water treatment processes. Their primary function is to remove harmful ions from water, enhancing its safety and quality. According to a recent report by the Water Research Foundation, these exchangers can effectively reduce contaminants by up to 90%. This efficiency makes them essential in both municipal and industrial applications.

In water treatment plants, phe exchangers are used to soften hard water. They replace calcium and magnesium ions with sodium or potassium. This process leads to improved water quality and prevents scaling in piping systems. These exchangers can also help in the removal of heavy metals, providing cleaner water. The demand for such systems is growing. The global market for water treatment technologies is projected to reach $343 billion by 2025.

While phe exchangers offer many benefits, there are challenges to consider. For instance, the regeneration process can be costly and generate waste. Efficiency can vary based on water composition and flow rates. Users must also monitor the system regularly. Ignoring maintenance can lead to reduced performance or complete system failure. Reflecting on these aspects is vital for optimizing their use in water treatment.

Phe exchangers play a crucial role in enhancing energy efficiency and promoting sustainability. These devices transfer heat between two or more fluids, significantly reducing energy waste in various processes. By optimizing thermal management, they contribute to a more efficient energy system. Factories and power plants can harness this advantage, cutting down operational costs.

While the benefits are clear, there are challenges. Not all phe exchangers perform seamlessly in varying conditions. Factors like fluid properties and design flaws can impact their efficiency. This underscores the need for rigorous testing and smart design choices. Moreover, the installation and maintenance of these exchangers must be handled carefully. Improper upkeep can lead to inefficiencies and even catastrophic failures.

The impact extends beyond just energy savings. Improved efficiency leads to lower carbon emissions, fostering a greener environment. However, not every application reaps these benefits equally. Some industries may struggle with specific heat transfer requirements. Continuous research is essential to ensure that phe exchangers evolve and meet the diverse demands of modern energy systems.

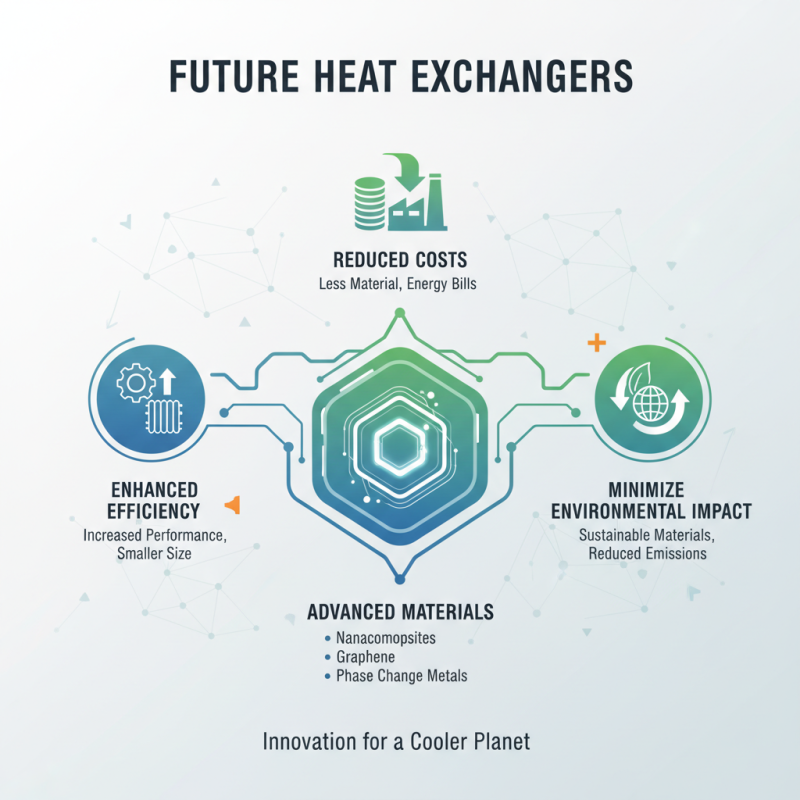

The future of Phe exchanger technology is promising. Innovations are emerging that enhance efficiency, reduce costs, and minimize environmental impact. Advanced materials are being developed to improve heat exchange capabilities. These materials increase performance while decreasing size and weight.

New designs aim to optimize fluid dynamics as well. Enhanced flow patterns can lead to better heat transfer and energy savings. However, challenges remain. Some designs may be complex and costly to manufacture. Simplifying these processes is essential for wider adoption.

Tips: Regular maintenance is key for efficiency. Check your systems frequently. Ensuring proper flow rates can prevent issues.

Another trend is the integration of smart technology. Sensors can monitor performance, predict failures, and suggest optimizations. This data can lead to informed decisions, maximizing system lifespan. Still, implementing such technology requires investment and expertise. Many industries may struggle with this transition, and it's important to evaluate readiness before diving in.

Overall, Phe exchangers are on the brink of a technological revolution, but careful consideration of the implementation and maintenance will be crucial.