Leave Your Message

Plate heat transfer technology has emerged as a critical component in various modern industries, playing a vital role in enhancing energy efficiency and reducing operational costs. According to a report by MarketsandMarkets, the global market for heat exchangers, including plate heat transfer systems, is projected to reach over $19 billion by 2026, driven by the increasing demand for effective thermal management solutions across sectors such as food and beverage, chemical processing, and HVAC. The significance of plate heat transfer lies in its ability to maximize heat recovery while minimizing space requirements, thereby contributing to sustainable industrial practices. With advancements in materials and design, the efficiency of plate heat exchangers continues to outperform traditional systems, positioning them as a preferred choice for businesses aiming to optimize their thermal processes and meet stringent regulatory compliance. In this blog, we will explore the various applications and benefits of plate heat transfer technology in modern industries.

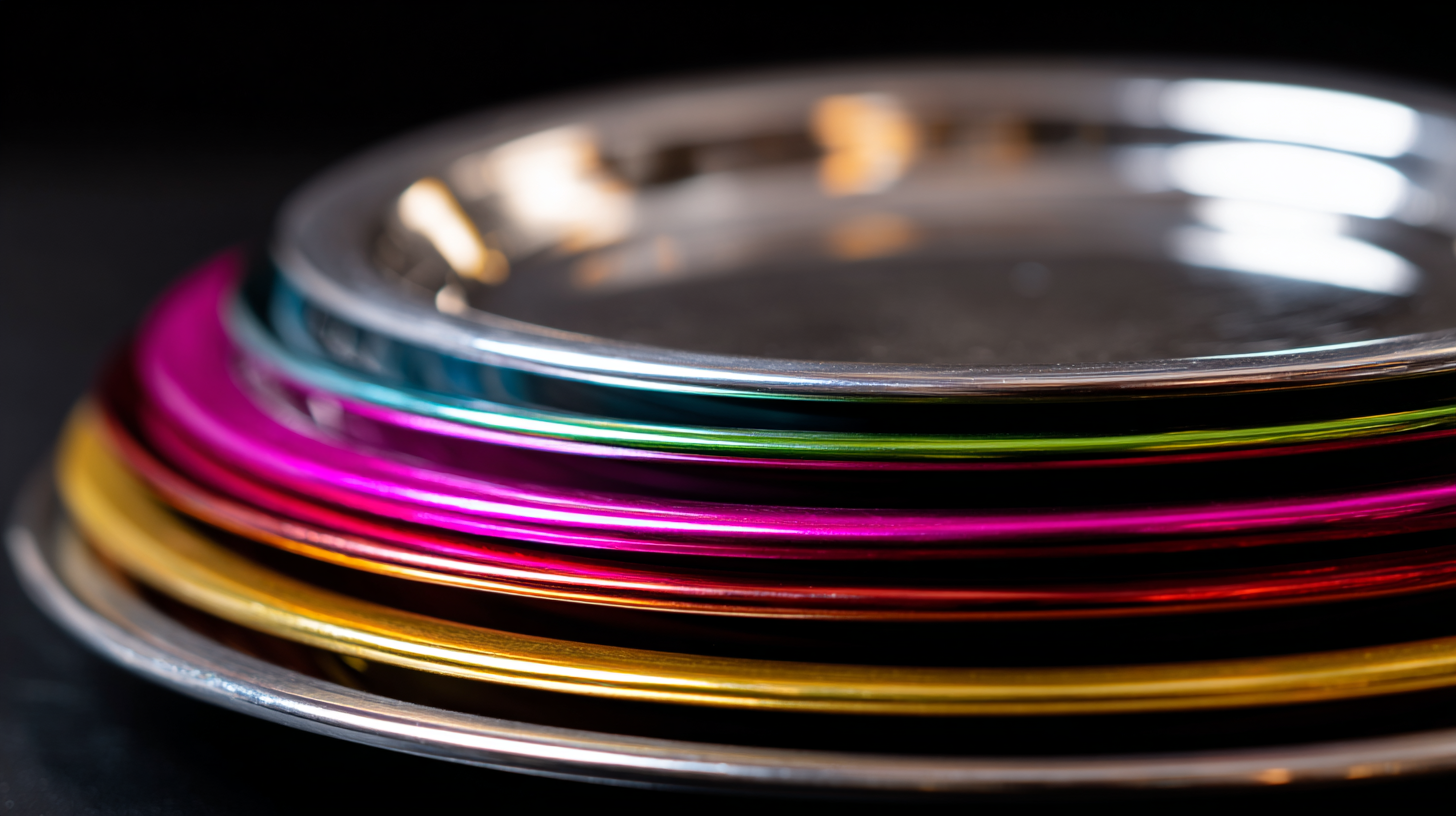

Plate heat exchangers (PHEs) have emerged as essential components in enhancing energy efficiency across various industries. Unlike traditional heat exchangers, PHEs utilize thin, corrugated plates to transfer heat between fluids, significantly improving the heat transfer surface area. This design not only enhances thermal performance but also minimizes energy consumption, providing a cost-effective solution for industries aiming to reduce their ecological footprint. The compact nature of PHEs makes them ideal for space-limited applications, thus allowing for easier integration into existing systems.

In industries such as food processing, pharmaceuticals, and HVAC, the role of PHEs is particularly pronounced. For instance, in the food industry, they ensure that products are pasteurized effectively while maintaining quality and taste. Furthermore, PHEs are adept at recovering waste heat, which can be reintegrated into the process, showcasing their potential for energy reuse. By optimizing thermal management and reducing energy wastage, plate heat exchangers not only boost operational efficiency but also contribute to sustainability goals, making them indispensable in modern industrial applications.

Plate heat exchangers (PHEs) have emerged as a cornerstone in modern industries, especially with increasing demands for energy efficiency and sustainability. Understanding the efficiency metrics of these devices is crucial for optimizing their performance. According to the 2023 report by the International Energy Agency, plate heat exchangers can achieve thermal efficiency rates exceeding 90%, significantly higher than traditional shell-and-tube designs, which typically hover around 70-80%. This increased efficiency not only minimizes energy consumption but also reduces operational costs, making PHEs a preferred choice for industries such as food processing, pharmaceuticals, and HVAC.

Moreover, the compactness of plate heat exchangers contributes to their enhanced efficiency. A report by the Heat Transfer Engineering Journal indicates that PHEs require up to 50% less space than conventional heat exchangers, allowing companies to optimize facility layouts without sacrificing performance. The ability to handle a wide range of temperatures and pressures further solidifies their position in various applications, reinforcing the importance of efficiency metrics in evaluating their performance. As industries strive for sustainable practices, leveraging the advantages of plate heat transfer technology will remain pivotal in enhancing overall operational efficiencies.

Plate heat exchangers (PHEs) play a crucial role in the chemical and food processing industries due to their efficiency and compact design. In the chemical sector, PHEs facilitate efficient heat transfer during reactions, helping to maintain optimal temperatures for various processes. Their ability to handle high pressures and corrosive materials makes them ideal for a range of chemical applications, from petroleum refining to chemical synthesis.

In the food processing industry, the importance of hygiene and efficiency cannot be overstated. PHEs provide a sanitary means of heating or cooling food products without cross-contamination, thanks to their large surface area and design that allows for easy cleaning. They are often used in pasteurization processes, ensuring food safety while minimizing energy consumption.

Tips: When selecting a plate heat exchanger for specific applications, consider factors like material compatibility, temperature ranges, and cleaning methods. Regular maintenance is essential to keep PHEs in optimal working condition, so implement a routine inspection protocol. Moreover, understanding the flow arrangement—whether counterflow, parallel flow, or cross flow—can significantly impact performance and efficiency.

Plate heat exchangers (PHEs) have become increasingly significant in modern industries due to their efficiency and compact design when compared to traditional heat transfer methods. Unlike conventional shell-and-tube heat exchangers, which require larger spaces and often involve a complex arrangement of tubes, PHEs utilize a series of plates to facilitate heat transfer. This design not only minimizes the equipment footprint but also enhances the heat transfer surface area, leading to better thermal performance. As industries strive for energy conservation and higher efficiency, plate heat exchangers stand out for their ability to handle a wide range of temperatures and pressures.

Furthermore, the ease of maintenance and cleanability of plate heat exchangers is a crucial advantage over traditional systems. PHEs can be easily disassembled for cleaning, which is vital in applications requiring strict hygiene standards, such as food processing and pharmaceuticals. In contrast, shell-and-tube exchangers may pose challenges during maintenance, leading to increased downtime. Additionally, the ability to customize the plate configuration in PHEs allows for optimization according to specific industrial needs, making them a more adaptable solution. As industries continue to evolve, the comparative benefits of plate heat exchangers over traditional methods underscore their growing significance in enhancing operational efficiency and sustainability.

Plate heat transfer technologies play a crucial role in modern industries, particularly as we witness a shift towards more efficient and sustainable energy solutions. Recent reports indicate that the plate heat exchanger market is projected to grow significantly, driven by the increasing demand for energy-efficient systems and the necessity for waste heat recovery in various industrial processes. In fact, plate heat exchangers are becoming vital not just for temperature regulation but also for optimizing energy usage and reducing operational costs.

As we advance into the future, innovative trends are emerging within the plate heat transfer sector. The integration of artificial intelligence and digital technologies is expected to transform the landscape significantly. Recent data suggest that by 2025, the scale of intelligent computing in China will reach 1037.3 EFLOPS, enabling industries to manage and analyze vast amounts of data efficiently. This, coupled with advancements in plate heat exchanger design and material science, will foster innovations aimed at maximizing thermal efficiency and enhancing the overall performance of these systems. Moreover, exhibitions like the CTEF Shanghai Chemical Exhibition are showcasing state-of-the-art technologies and solutions, highlighting the collaborative efforts within the industry to push the boundaries of what's possible in heat transfer technology.

| Industry | Current Application | Future Trends | Innovations |

|---|---|---|---|

| Food and Beverage | Pasteurization, Cooling | Increased Efficiency, Sustainability | Advanced Plate Configurations, Enhanced Cleanability |

| Chemical Processing | Heat Exchangers, Reactors | Smart Heat Management, Process Integration | Use of Novel Materials, Automation |

| HVAC | Heating and Cooling | Energy-efficient Systems, Smart Control | Innovative Insulation Technologies, IoT Integration |

| Pharmaceuticals | Temperature Control in Manufacturing | Enhanced Regulatory Compliance, Risk Mitigation | Real-time Monitoring Technologies, Adaptive Systems |

| Energy | Cooling Systems in Power Plants | Renewable Energy Integration, Waste Heat Recovery | Nano-coatings, Enhanced Performance Modelling |