Leave Your Message

The importance of Phe Exchangers in modern industrial applications cannot be overstated, as they play a crucial role in enhancing energy efficiency and process optimization across various sectors. According to a recent market analysis by Research and Markets, the global heat exchanger market, which prominently features Phe Exchangers, is projected to reach $22.3 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.5%. This growth is driven by increasing demands for energy conservation and sustainable manufacturing processes.

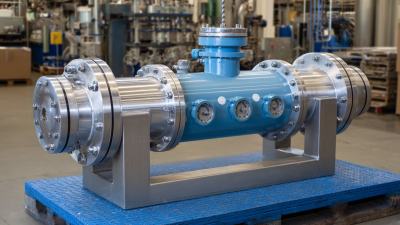

Phe Exchangers, known for their compact design and high thermal efficiency, are widely utilized in industries such as chemical processing, HVAC, pharmaceuticals, and food production. As the industry shifts towards greener technologies and stringent environmental regulations, the role of Phe Exchangers in facilitating heat recovery and reducing operational costs becomes increasingly vital, solidifying their position as a cornerstone of modern industrial practices.

In modern industrial applications, plate heat exchangers (PHEs) play a pivotal role in enhancing energy efficiency across various sectors, including chemical manufacturing, food processing, and thermal power generation. Their compact design and high reliability make them ideal for transferring heat between two fluids, often leading to reduced energy consumption and operational costs. The inherent efficiency of PHEs allows industries to maintain optimal operating temperatures while minimizing energy losses, which is crucial for meeting sustainability goals in today's environmentally conscious market.

Furthermore, ongoing innovations in PHE design, such as the integration of additively manufactured components and advanced materials, are set to revolutionize their performance. For instance, using molten salt with supercritical carbon dioxide in heat exchangers for solar thermal power generation not only demonstrates significant improvements in heat transfer efficiency but also supports the transition to renewable energy sources. As industries continue to adopt these cutting-edge technologies, the importance of PHEs in driving energy efficiency and boosting overall productivity becomes increasingly evident, solidifying their status as indispensable assets within modern industrial settings.

In recent years, Plate Heat Exchangers (PHE) have gained increasing recognition across various industries due to their efficiency and compact design. A noteworthy report highlights that the global PHE market is expected to witness significant growth, projected to reach approximately $6.5 billion by 2025. This growth is driven by the expanding demand for energy-efficient systems in HVAC, chemical processing, and food production.

The application of data-driven techniques in managing PHE systems has further enhanced their operational efficiency. For instance, a study from a leading analysis firm indicates that implementing AI-driven insights can improve the thermal performance of PHEs by up to 25%. Such advancements enable industries to not only reduce energy consumption but also optimize maintenance schedules, significantly lowering operational costs.

Furthermore, industries are increasingly leveraging tools such as Power BI to visualize and interpret data related to PHE performance. A recent workshop in the healthcare sector emphasized the importance of data analytics in quality management, demonstrating how real-time data can lead to better decision-making processes in maintaining system integrity and performance. The convergence of data analytics and PHE technology is paving the way for smarter industrial applications, reinforcing the role of these exchangers in modern engineering practices.

In modern industrial applications, the significance of Plate Heat Exchangers (PHE) has surged, primarily due to their enhanced efficiency compared to traditional heat exchangers. A comparative analysis reveals that PHEs offer superior thermal performance, especially in environments demanding rigorous temperature control. For instance, studies indicate that PHEs can achieve a maximum flow velocity of 5 m/s, optimizing heat transfer while minimizing energy costs. This is in stark contrast to traditional shell-and-tube exchangers, which typically operate at lower velocities, thus resulting in higher thermal resistance and lower overall efficiency.

In modern industrial applications, the significance of Plate Heat Exchangers (PHE) has surged, primarily due to their enhanced efficiency compared to traditional heat exchangers. A comparative analysis reveals that PHEs offer superior thermal performance, especially in environments demanding rigorous temperature control. For instance, studies indicate that PHEs can achieve a maximum flow velocity of 5 m/s, optimizing heat transfer while minimizing energy costs. This is in stark contrast to traditional shell-and-tube exchangers, which typically operate at lower velocities, thus resulting in higher thermal resistance and lower overall efficiency.

Moreover, the adaptability of PHEs to various operating conditions further underscores their industrial relevance. Data from recent reviews highlight that PHEs can operate under maximum pressures of up to 30 bar, making them suitable for a range of applications, from food processing to thermal power plants. This capability not only enhances process reliability but also supports efficient heat recovery systems, providing a substantial edge over traditional designs. As industries strive for sustainability and energy efficiency, the adoption of PHE technology continues to grow, setting a new standard in heat exchange applications.

In today’s industrial landscape, the significance of PHE (Plate Heat Exchanger) technology cannot be overstated, particularly in the context of reducing the carbon footprint. PHE exchangers optimize thermal efficiency, allowing industries to heat and cool fluids using less energy. This process not only lowers operational costs but also minimizes greenhouse gas emissions. Recent statistics indicate that industries utilizing PHE technology can achieve energy savings of up to 30%, showcasing a clear path toward more sustainable practices.

To maximize the benefits of PHE exchangers, consider implementing regular maintenance practices. Keeping the plates clean and ensuring proper alignment can significantly enhance their efficiency and lifespan. Additionally, conducting periodic inspections can help identify potential issues before they escalate, maintaining optimal performance.

Another tip is to invest in advanced PHE models designed for your specific operational needs. Customization can lead to improved thermal performance and energy savings tailored to your unique industrial processes. By focusing on these strategies, businesses not only contribute to a greener planet but also position themselves competitively in an increasingly eco-conscious market.

| Application Area | Annual CO2 Reduction (Metric Tons) | Energy Savings (GWh) | Percentage of Efficiency Improvement | Investment (Million USD) |

|---|---|---|---|---|

| Chemical Processing | 500,000 | 200 | 15% | 50 |

| Food & Beverage | 300,000 | 150 | 10% | 30 |

| HVAC Systems | 400,000 | 180 | 12% | 40 |

| Power Generation | 600,000 | 250 | 18% | 70 |

| Pharmaceuticals | 250,000 | 120 | 9% | 25 |

The importance of plate heat exchangers (PHE) in modern industrial applications cannot be overstated, particularly as we look towards future trends driving innovation and sustainability. According to a recent report from the Global Plate Heat Exchanger Market, the demand for PHE technology is projected to grow at a CAGR of 6.5% from 2023 to 2030. This growth is largely fueled by the increasing need for energy-efficient solutions across various sectors, including food and beverage, chemical processing, and HVAC systems.

Innovations in PHE technology are transforming how industries approach thermal management. Advanced designs, such as those employing new materials and configurations, provide enhanced thermal efficiency and reduced energy consumption. For instance, the integration of digital monitoring systems is now enabling real-time assessments of heat transfer performance, leading to proactive maintenance strategies. Moreover, a study by Transparency Market Research highlights that eco-friendly refrigerants used in PHEs can reduce energy consumption by up to 20%, resulting in both cost savings and significant environmental benefits. As industries continue to prioritize sustainability, the evolution of PHE technology will undoubtedly play a critical role in shaping a more energy-conscious future.