Leave Your Message

In today's industrial landscape, optimizing Heat Exchanger efficiency is paramount for enhancing overall system performance and reducing operational costs. According to a report by the U.S. Department of Energy, poorly maintained heat exchangers can result in efficiency losses of over 25%, significantly impacting energy consumption and increasing greenhouse gas emissions. By leveraging data-driven insights and implementing best practices, organizations can not only improve heat transfer efficiency but also extend the lifespan of these critical components. Recent advancements in analytics and monitoring technologies provide invaluable data, enabling engineers to identify inefficiencies, predict maintenance needs, and implement timely interventions. As the demand for energy-efficient solutions continues to rise, optimizing Heat Exchanger performance becomes an essential focus for industries aiming for sustainability and profitability.

In the pursuit of optimizing heat exchanger efficiency, understanding efficiency metrics is crucial. Heat exchangers are pivotal in various applications, from industrial processes to residential heating systems, making it essential to evaluate their performance effectively. Key metrics, such as effectiveness, thermal resistance, and pressure drop, provide insights into the exchanger's operational efficacy. These metrics not only inform maintenance practices but also guide design improvements and operational adjustments, ensuring that the systems contribute to reduced energy consumption and lower carbon emissions.

As energy efficiency emerges as the "first fuel" in clean energy transitions, leveraging data-driven insights can significantly enhance heat exchanger performance. Recent advancements in predictive modeling enable the analysis of various factors affecting the efficiency of these systems. For example, understanding the characteristics of microchannel heat exchangers highlights the impact of structural changes on thermal performance. Additionally, integrating machine learning approaches to optimize working fluid compositions can lead to substantial gains in both thermal and rheological performance, thereby fostering sustainable energy practices and reinforcing the imperative for cleaner energy sources.

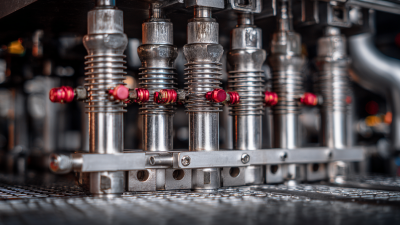

Leveraging data analytics for enhanced heat exchanger performance is crucial in today's industrial landscape, where efficiency directly impacts operational costs and environmental sustainability. By utilizing advanced data analytics tools, companies can gather real-time performance data from their heat exchangers. This data includes temperature differentials, flow rates, and pressure drops, allowing for a thorough understanding of the system's operational parameters. Through continuous monitoring, these insights can help identify inefficiencies or potential failures before they lead to significant downtime or energy losses.

Furthermore, data-driven approaches enable predictive maintenance strategies, wherein analytics forecast when a heat exchanger might require servicing. By analyzing historical performance data, manufacturers can pinpoint patterns and detect anomalies early on. This proactive stance not only optimizes maintenance schedules but also extends the lifespan of the equipment. Implementing these best practices, powered by comprehensive data analytics, ultimately enhances the overall performance of heat exchangers, leading to improved energy efficiency and reduced operational costs.

To maximize the efficiency of heat exchangers, regular maintenance is crucial. Several best practices can be implemented to ensure that these systems operate at their highest capacity. First, routine inspections should be conducted to identify any signs of wear and tear, scaling, or fouling. Neglecting these issues can lead to significant performance degradation and increased energy consumption.

Tips: Consider establishing a maintenance calendar that outlines specific inspections and cleaning tasks based on operational hours and system type. This proactive approach helps in catching potential problems early and prevents costly downtime.

Furthermore, utilizing data-driven insights can enhance the maintenance process. By monitoring temperature, pressure, and flow rates, manufacturers can analyze performance trends and pinpoint inefficiencies. This data can inform targeted adjustments or upgrades that optimize heat exchanger performance.

Tips: Invest in advanced analytics tools to track real-time data from your heat exchangers. This information can not only lead to immediate efficiency improvements but also supports long-term strategic planning for equipment upgrades and replacements.

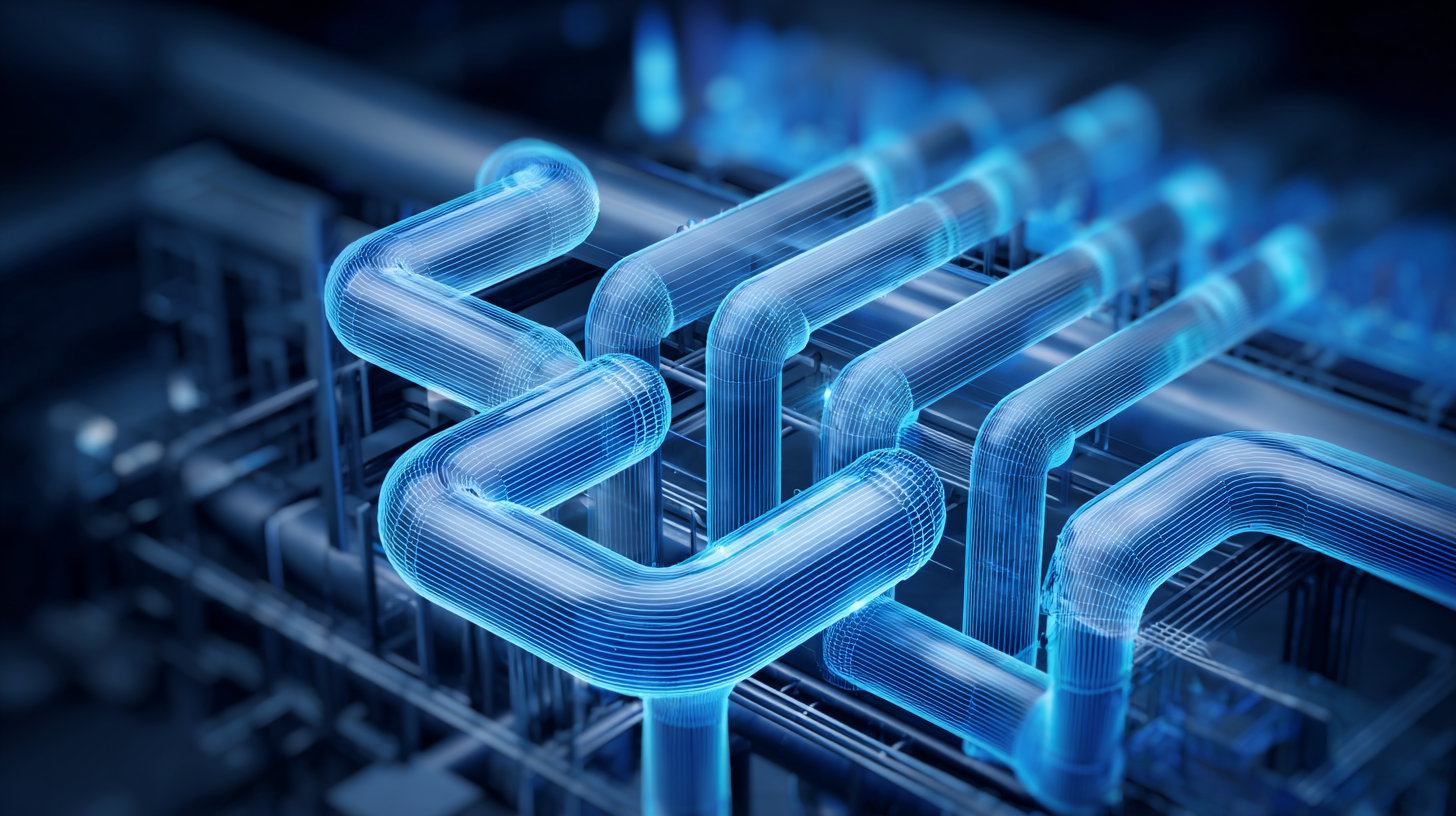

Real-time monitoring systems are revolutionizing the management of heat exchanger efficiency by providing immediate access to crucial operational data. These systems enable operators to track performance metrics such as temperature differentials, flow rates, and pressure drops in real time, facilitating swift decision-making. By continuously gathering and analyzing this data, facilities can promptly identify inefficiencies and implement corrective measures, ultimately enhancing both performance and energy savings.

Real-time monitoring systems are revolutionizing the management of heat exchanger efficiency by providing immediate access to crucial operational data. These systems enable operators to track performance metrics such as temperature differentials, flow rates, and pressure drops in real time, facilitating swift decision-making. By continuously gathering and analyzing this data, facilities can promptly identify inefficiencies and implement corrective measures, ultimately enhancing both performance and energy savings.

Tips: To maximize the effectiveness of real-time monitoring, consider integrating predictive analytics. This can help forecast potential failures before they occur, minimizing downtime. Additionally, regular training for staff on using these systems can ensure that your team can respond to anomalies quickly and effectively.

Moreover, setting up automated alerts can further fine-tune operations. These alerts can notify team members when performance deviates from established norms, prompting immediate investigation. By leveraging real-time data in these ways, organizations not only enhance the reliability of their heat exchangers but also pave the way for continuous improvement initiatives that support long-term operational excellence.

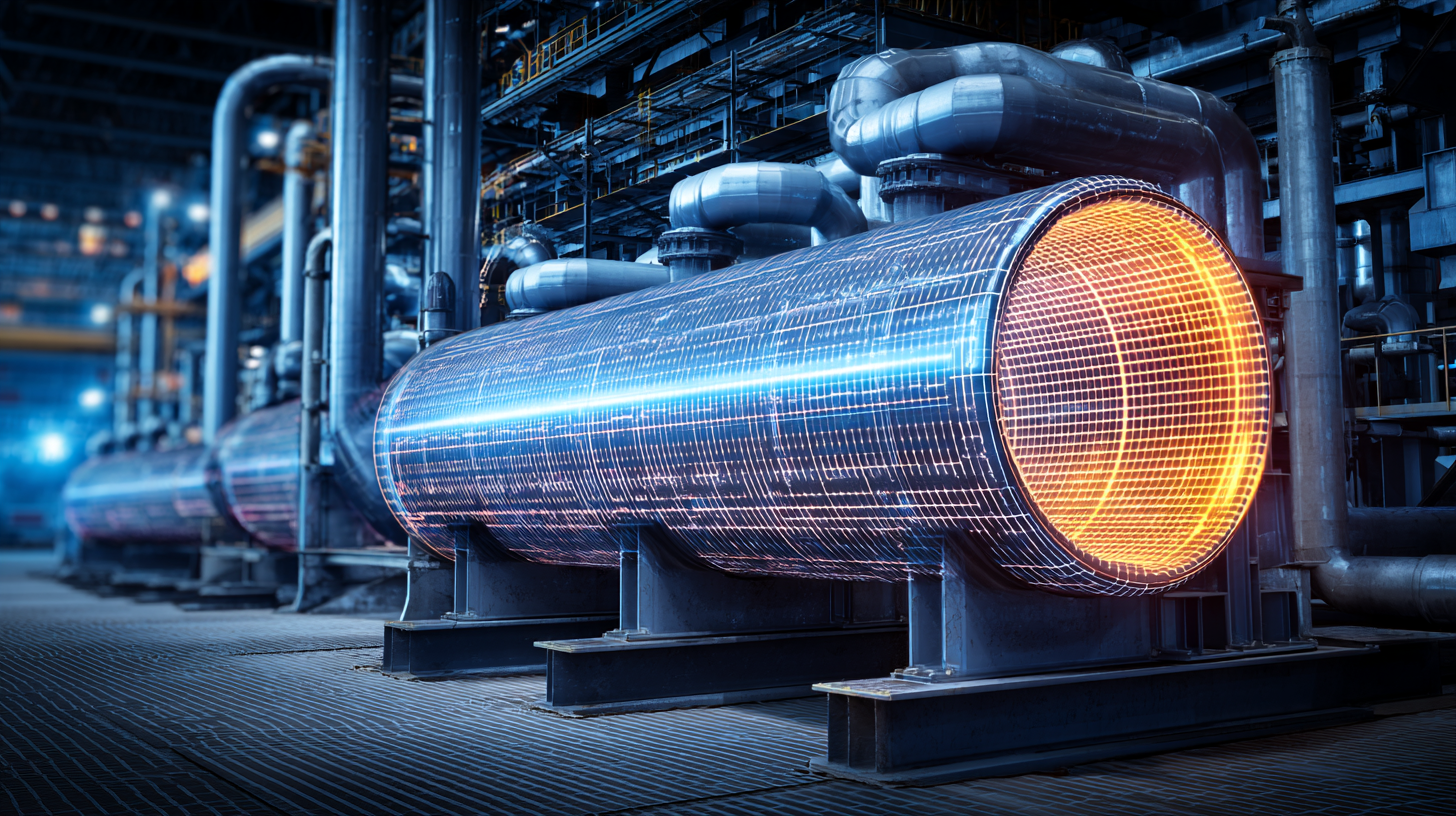

In the quest for enhanced heat exchanger efficiency, leveraging simulation and modeling techniques has proven invaluable. These approaches allow engineers to visualize fluid dynamics and thermal interactions within heat exchangers, unveiling potential design modifications before physical implementation. By creating detailed models, one can assess various configurations and materials, ultimately leading to improved heat transfer rates and energy savings.

**Tips:** When using simulation software, ensure to incorporate all parameters such as temperature ranges, pressure drops, and fluid properties. A comprehensive model provides the most accurate predictions, making it easier to identify inefficiencies.

Additionally, sensitivity analysis can highlight the impact of slight changes in design parameters on overall performance. This technique not only aids in refining existing systems but also serves as a foundation for innovative designs tailored to specific applications. Identifying optimal flow arrangements, such as counterflow vs. parallel flow, can further boost operational efficiency.

**Tips:** Keep an eye on the cost-benefit ratio when modifying designs. Sometimes the most efficient solution may not be the most economical. Evaluating the feasibility of designs in simulation can save both time and resources while maximizing efficiency.