Leave Your Message

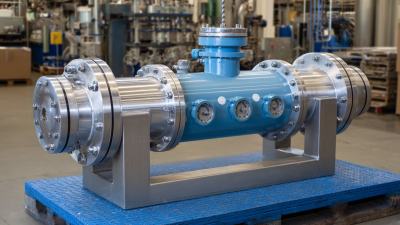

In the realm of industrial processes, the efficiency and reliability of heat exchangers are paramount for optimal operational performance. According to a report by the Heat Exchange Institute, improper maintenance can lead to a 10-15% reduction in efficiency, resulting in increased energy costs and potential system failures. Regular heat exchanger maintenance is not only crucial for minimizing downtime but also for extending the lifecycle of these vital components.

Industry studies indicate that facilities implementing a structured maintenance program can achieve a 30% increase in energy efficiency, underscoring the importance of proactive measures. This guide explores essential strategies and best practices for effective heat exchanger maintenance, ensuring systems operate at peak performance and fostering long-term sustainability in industrial operations.

Regular heat exchanger maintenance is crucial for ensuring optimal performance in industrial settings. According to a report by the Heat Exchange Institute, poorly maintained heat exchangers can lead to efficiency losses of up to 40%. This underscores the importance of a consistent maintenance schedule to prevent costly downtimes and inefficiencies. By routinely checking for leaks, blockages, and corrosion, facilities can enhance the reliability and lifespan of their heat exchangers, ultimately contributing to more sustainable operations.

Tips for Maintenance:

Investing in these maintenance practices not only boosts operational efficiency but also reduces energy consumption, aligning with industry efforts to meet sustainability targets.

Regular maintenance is essential for ensuring

optimal performance of heat exchangers. During routine maintenance checks, several key components should be carefully inspected to avoid inefficiencies and costly breakdowns.

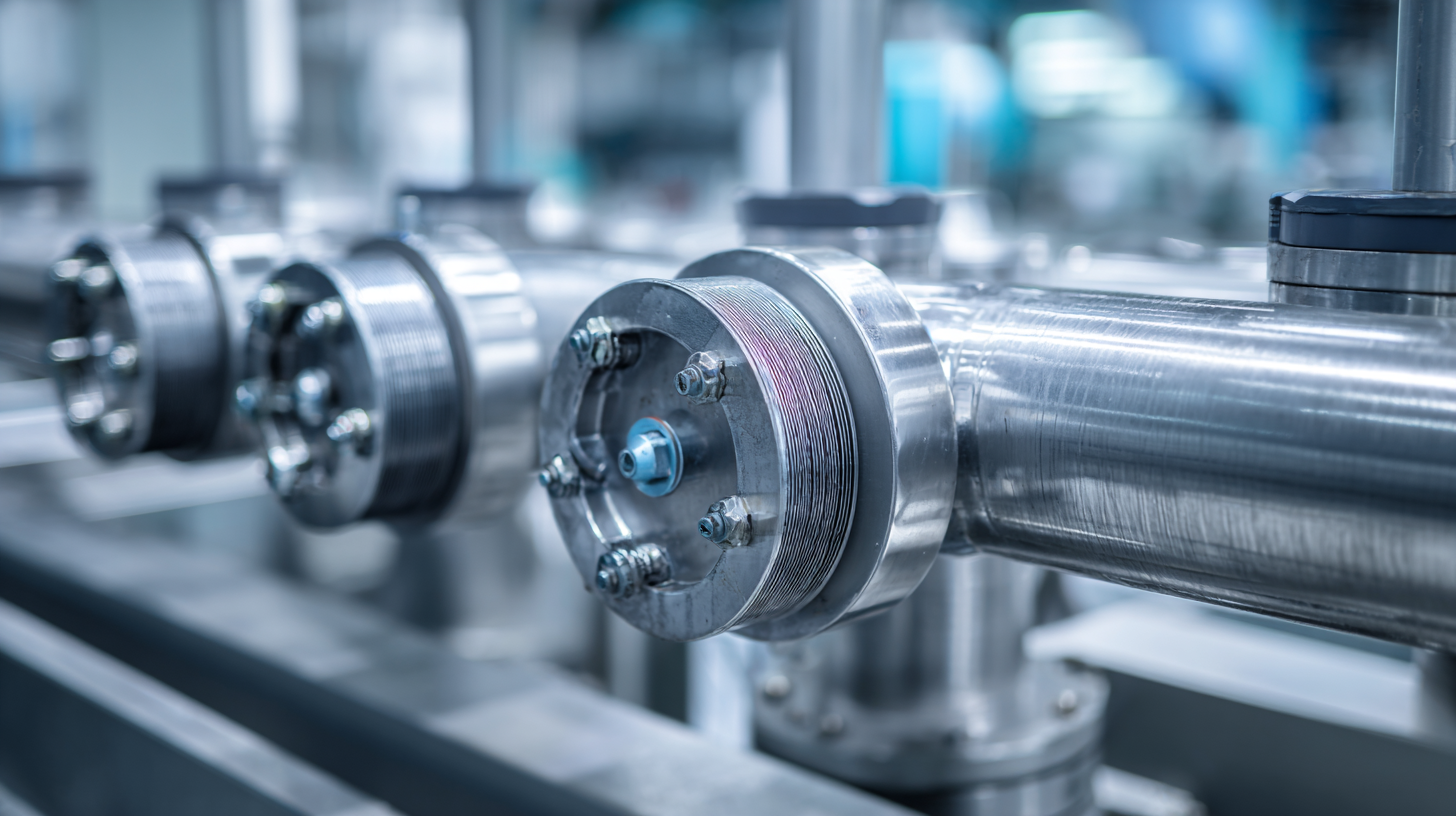

First, check for any signs of corrosion or fouling within the heat exchanger, as these factors can significantly impair heat transfer efficiency. Clean the surfaces to ensure maximum heat exchange and inspect the tubes for any blockages or leaks.

Additionally, it is important to assess the seals and gaskets for wear and tear. Compromised seals can lead to fluid leaks, which not only disrupt system performance but can also pose safety risks. Lastly, evaluate the operational parameters, such as pressure and temperature readings, to ensure that the system is functioning within its designed specifications. Regular attention to these components will enhance the reliability and lifespan of heat exchangers, allowing for better energy efficiency and performance.

Regular cleaning and servicing of heat exchangers are vital for maintaining optimal performance and prolonging equipment lifespan. According to a report by the U.S. Department of Energy, poorly maintained heat exchangers can lose up to 25% of their efficiency due to fouling and corrosion. Best practices for maintaining these critical components include scheduled inspections, thorough cleaning, and effective thermal performance assessments. Employing methods such as chemical cleaning or high-pressure water jetting can significantly reduce the buildup of scale and contaminants, enhancing overall heat transfer capabilities.

In addition to cleaning, regular servicing should involve checking for leaks, integrity of gaskets, and ensuring that temperature and pressure readings are within specified limits. A study by the Heat Exchange Institute suggests that proactive maintenance not only improves efficiency but can also lead to a reduction in energy costs by as much as 10-15%. Implementing a routine maintenance schedule, informed by performance data and operational parameters, is crucial for maximizing the operational lifespan and efficiency of heat exchangers in various industrial applications.

This chart illustrates the impact of regular maintenance on the efficiency of heat exchangers over a period of time. The data represents the performance score measured in efficiency percentage based on maintenance frequency.

Heat exchangers are critical components in various industrial applications, and ensuring their optimal performance requires identifying and troubleshooting common issues. Recent studies indicate that effective maintenance hinges on reliable inspection data and accurate predictions regarding tube-bundle life. Failures in shell and tube exchangers often stem from inadequate design or operational oversight, emphasizing the necessity of robust reliability programs. For instance, research has shown that the plugging of tubes can significantly affect the functionality and lead to severe failures, highlighting the need for precise computational fluid dynamics (CFD) and finite element method (FEM) analyses to predict such outcomes.

Moreover, specific vulnerabilities, like tube-to-tubesheet joint failures, can have detrimental impacts on overall efficiency. A comprehensive review suggests that focused inspections and targeted interventions on these critical interfaces are essential for prolonging the lifespan of heat exchangers. For organizations, implementing these maintenance protocols not only mitigates risks but also enhances operational efficiency, aligning with findings that underscore the importance of proactive management strategies in preventing failures and ensuring the longevity of heat exchanger systems in challenging environments.

Regular maintenance of heat exchangers is crucial for ensuring optimal performance and longevity. According to the U.S. Department of Energy, routine inspections and maintenance can improve energy efficiency by up to 15%. However, the frequency of servicing is often a concern for facility managers. The general consensus within the industry suggests that heat exchangers should be inspected at least twice a year, with more frequent servicing recommended for systems operating in harsh environments or with heavy load cycles.

In addition to physical inspections, it is important to monitor key performance indicators such as pressure drop, temperature differential, and flow rates. Data from the Heat Exchange Institute indicates that maintaining proper flow rates can lead to a 20% increase in heat transfer efficiency. Furthermore, signs of fouling or scaling should not be overlooked; solutions like chemical cleaning can be implemented semi-annually to prevent long-term damage. By adhering to a structured maintenance schedule, not only can performance be optimized, but potential failures can be preemptively addressed, significantly reducing downtime and maintenance costs.