Leave Your Message

In 2023, the pursuit of energy efficiency has taken center stage in various industries, with Phe Heat Exchanger innovations leading the charge. As reported by the International Energy Agency (IEA), nearly 40% of global energy consumption is attributed to industrial processes, highlighting the urgent need for effective solutions. Phe Heat Exchangers, recognized for their superior thermal performance and compact design, can significantly reduce energy consumption and operational costs. According to a recent analysis by MarketsandMarkets, the global heat exchanger market is projected to reach $24 billion by 2026, driven by advancements in technologies related to Phe Heat Exchangers. This surge underscores the importance of embracing these innovations, not only for achieving sustainability goals but also for enhancing productivity across diverse sectors. As industries strive to maximize energy efficiency, Phe Heat Exchangers are poised to play a pivotal role in transforming operational practices in 2023 and beyond.

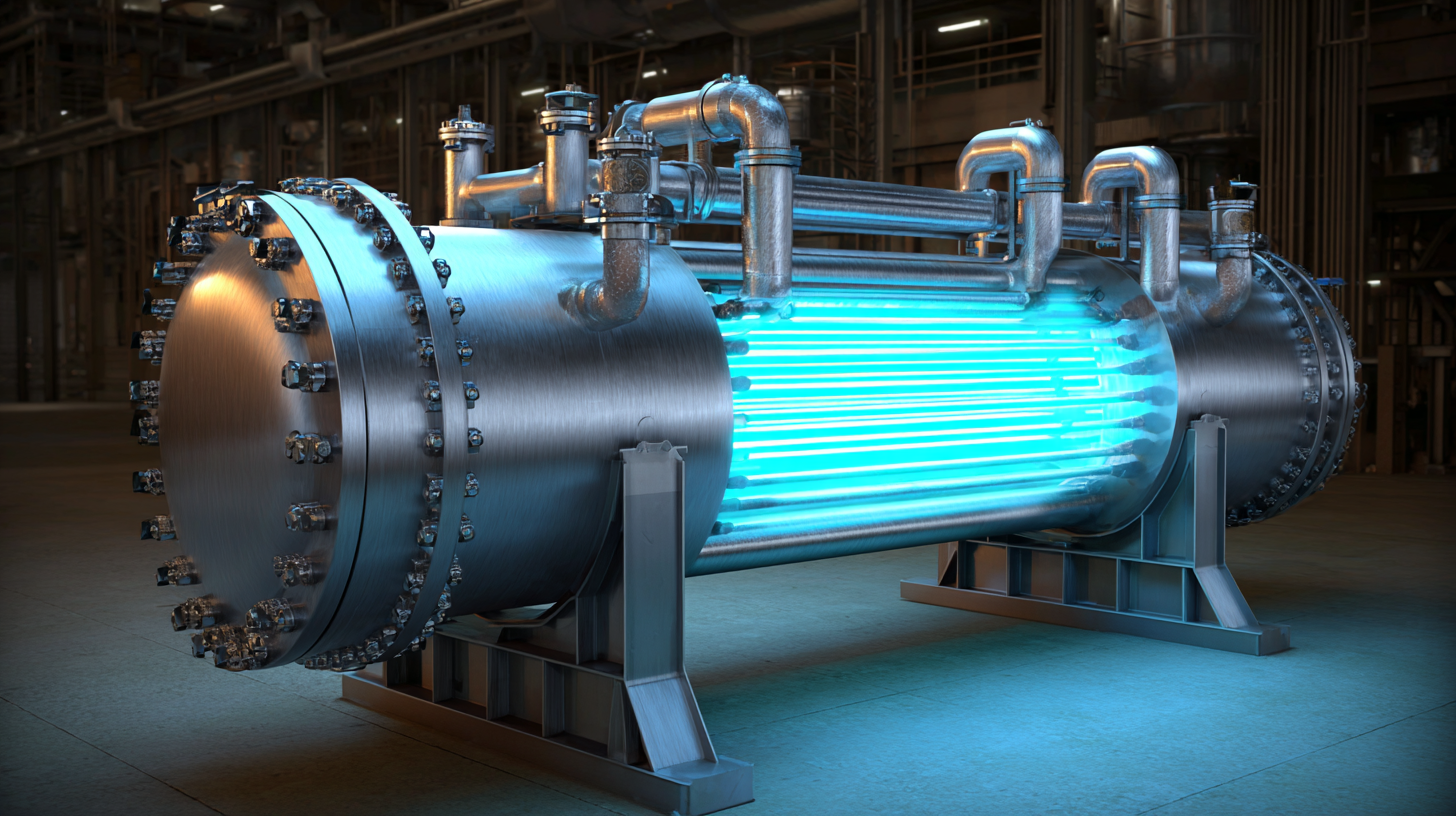

In 2023, the latest advancements in Plate Heat Exchanger (PHE) designs are reshaping the landscape of energy efficiency in industrial applications. The innovative designs focus on maximizing heat transfer capability while minimizing energy losses. New materials, such as advanced stainless steels and composites, enhance thermal conductivity and corrosion resistance, making these heat exchangers not only more efficient but also more durable in various operational environments.

Furthermore, the incorporation of modular designs in PHEs allows for flexibility in installation and maintenance. These modular systems enable customization based on specific process needs, enhancing overall performance. Enhanced drainage features and improved flow patterns reduce fouling rates, leading to longer operational periods and lower maintenance costs. The combination of these innovative designs ensures that industries can achieve optimal energy efficiency, significantly reducing their carbon footprint while meeting stringent regulatory standards.

In 2023, the significance of Plate Heat Exchanger (PHE) technology in industrial applications grows increasingly prominent, driven by a clear need for improved energy efficiency and sustainability. A recent report by the International Energy Agency (IEA) highlighted that industrial heating accounts for nearly 20% of global energy consumption. By integrating PHE systems, facilities can achieve energy savings of up to 30%, dramatically reducing their operational costs and environmental impact.

Moreover, the compact design of PHE units enhances their applicability in various sectors, from food processing to chemical manufacturing. According to a study published by the World Heat Transfer Conference, PHEs can increase heat recovery efficiency by 50% compared to traditional heat exchangers. This not only boosts productivity but also aligns with global sustainability goals, as businesses strive to minimize their carbon footprint. With the rapid advancement of PHE technology, industries are better positioned than ever to harness these innovations for a more efficient and sustainable future.

In 2023, the spotlight on energy efficiency has led many industries to consider the advantages of Plate Heat Exchangers (PHE) over traditional shell-and-tube designs. A report by the International Energy Agency (IEA) indicates that optimizing heat recovery can reduce energy consumption by up to 30%. This efficiency leap is primarily due to the larger surface area of PHEs, which facilitates superior heat transfer rates while requiring less operational space. Furthermore, PHEs boast lower maintenance costs, with studies showing that their compact design results in up to 20% less cleaning time compared to conventional units.

When evaluating PHE versus traditional heat exchangers, it's important to consider temperature effectiveness and flow arrangement flexibility. PHEs can handle higher thermal efficiencies with smaller temperature differences, leading to significant energy savings. According to a recent market analysis, installations of PHEs are projected to grow by 8% annually, driven by increasing industrial demands for sustainable operations.

**Tips:** When transitioning to PHE technology, always keep an eye on the design parameters specific to your application. Additionally, consider conducting a life-cycle cost analysis to better understand the long-term savings potential of investing in PHE systems. Finally, ensure proper training for maintenance staff, as knowledge about the unique aspects of PHEs is crucial for maximizing their operational lifespan.

This chart compares the energy efficiency of Plate Heat Exchangers (PHE) versus Traditional Heat Exchangers across various industries in 2023.

The landscape of heat exchange technology is witnessing significant advancements, particularly concerning the efficiency of plate heat exchangers (PHEs). As industries strive for more sustainable operations, the emphasis has been placed on evolving innovations that enhance thermal performance while minimizing energy consumption. In 2023, cutting-edge designs featuring improved plate corrugations and advanced material usage are set to redefine how heat exchangers operate, offering superior heat transfer rates and reduced pressure drops.

In addition to mechanical advancements, the integration of smart technologies is emerging as a critical trend in optimizing PHE efficiency. IoT-enabled solutions allow for real-time monitoring and control, facilitating predictive maintenance and ensuring optimal operational conditions. As industries increasingly adopt these innovations, efficiency in energy consumption rises, contributing to lower operational costs and a reduced carbon footprint. This synergy between innovative design and smart technology paves the way for a more energy-efficient future in heat exchange systems, enabling businesses to meet their sustainability goals while maximizing performance.

In 2023, various industries have successfully integrated Phe (Plate Heat Exchanger) innovations to optimize energy efficiency and achieve substantial cost savings. For instance, a major dairy processing plant reported a 30% reduction in energy consumption by implementing PHE technology. This transition not only minimized their operational costs but also significantly lowered their carbon footprint, showcasing the tangible benefits of energy-efficient practices.

Tips for maximizing the efficiency of PHE systems include regular maintenance checks to ensure optimal performance and promptly addressing any leaks or inefficiencies. Additionally, consider adjusting your process temperatures based on seasonal variations to avoid unnecessary energy expenditure. Implementing a monitoring system can also help identify areas for improvement, contributing to increased overall energy savings.

Another notable success story comes from a beverage company that retrofitted their existing heat exchangers with PHE systems, resulting in a monthly savings of thousands of dollars. The installation allowed for more effective heat recovery, leading to reduced energy demand and enhancing the sustainability of their operations. As businesses continue to recognize these benefits, the demand for innovative heat exchanger solutions is set to rise.

| Industry | Initial Efficiency (%) | Post-implementation Efficiency (%) | Energy Savings (kWh/year) | CO2 Reduction (tons/year) |

|---|---|---|---|---|

| Manufacturing | 65% | 85% | 250,000 | 50 |

| Food Processing | 70% | 90% | 300,000 | 60 |

| Chemical Plant | 75% | 92% | 400,000 | 80 |

| Agriculture | 60% | 80% | 150,000 | 30 |

| Textile | 68% | 87% | 200,000 | 40 |