Leave Your Message

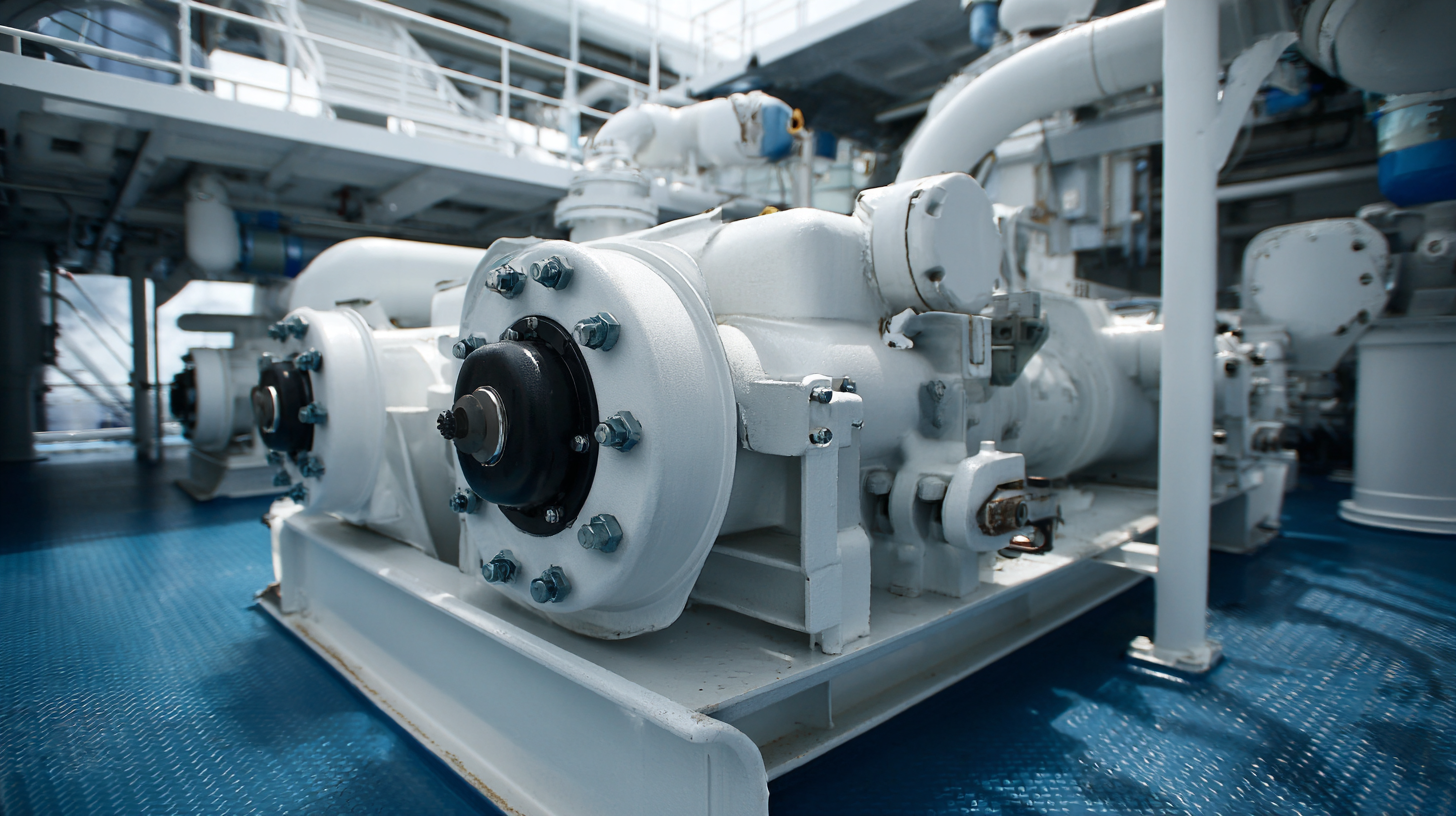

The significance of Marine Heat Exchangers in the maritime industry cannot be overstated, as they play a crucial role in maintaining optimal thermal efficiency on vessels. According to the 2021 report by the International Maritime Organization (IMO), marine heat exchangers contribute to energy savings of up to 30% by enabling better heat recovery and cooling processes in ship systems. These devices are essential for various applications, including engine cooling, fuel oil heating, and freshwater production.

With the maritime sector facing increasing pressure to reduce emissions and enhance operational efficiency, understanding the intricacies of Marine Heat Exchangers is vital for nautical engineers. This article delves into the key aspects of design, maintenance, and troubleshooting of Marine Heat Exchangers, providing essential insights to navigate the challenges faced in modern maritime operations.

Marine heat exchangers play a crucial role in the efficient operation of various nautical systems, ensuring temperature regulation in engines, cooling systems, and other critical components. At their core, these devices transfer heat between two or more fluids, which can be in either liquid or gas form. By maintaining optimal temperatures, marine heat exchangers help prevent overheating and improve the overall performance of vessels, ranging from luxury cruise ships to smaller recreational boats.

Understanding the basic principles behind marine heat exchangers is essential for nautical engineers. These systems typically use either a shell-and-tube or plate design to maximize the surface area available for heat transfer. The efficiency of a heat exchanger largely depends on factors such as the flow rates of the fluids involved, the temperature differential, and the materials used in construction. By focusing on these elements, engineers can optimize the design and functionality of heat exchangers, ensuring a safe and comfortable experience for those onboard while also enhancing operational reliability.

In the realm of marine engineering, the design of heat exchanger systems is crucial for optimizing energy efficiency and environmental sustainability. Key considerations for these systems include material selection, flow arrangement, and heat transfer efficiency. Utilizing innovative designs like the S-type sieve tray column can enhance liquid distillation processes by improving the efficiency of heat exchange within marine environments. Such advancements not only increase the operational effectiveness of vessels but also significantly reduce their ecological impact.

Moreover, the ongoing exploration of alternative fuel options, such as LNG, methanol, and ammonia, closely relates to heat exchanger design. These fuels often require specialized heat management systems to maximize performance and minimize emissions. Integrating hybrid power and cooling facilities that incorporate waste heat recovery from marine diesel engines exemplifies how modern design strategies can lead to more sustainable operations. By focusing on these design considerations, nautical engineers can contribute to a low-carbon future while ensuring that vessels remain competitive in an evolving market.

Marine heat exchangers play a crucial role in ensuring the efficiency and safety of various systems aboard vessels. However, their operation is not without challenges. One common issue is fouling, where deposits accumulate on heat exchange surfaces, reducing efficiency and increasing operational costs. Regular cleaning schedules and the use of chemical inhibitors can mitigate this problem significantly. Engineers must also be vigilant in selecting suitable materials that resist corrosion and fouling based on the specific marine environment they operate in.

Another challenge faced by nautical engineers is maintaining optimal flow rates through the heat exchanger. Inadequate flow can lead to hotspots, which may cause overheating and ultimately failure. To counter this, engineers must carefully design pump systems and monitor flow conditions continuously. Implementing advanced control systems can provide real-time data, allowing for quick adjustments to maintain ideal performance. Addressing these challenges ensures that marine heat exchangers function effectively, supporting overall vessel performance and safety.

| Challenge | Description | Potential Causes | Solutions |

|---|---|---|---|

| Corrosion | Degradation of heat exchanger materials due to chemical reactions. | Presence of saltwater, improper material selection. | Use corrosion-resistant materials, apply protective coatings. |

| Scaling | Build-up of mineral deposits on heat exchanger surfaces. | Hard water supply, inadequate water treatment. | Implement water softening systems, regular cleaning schedules. |

| Leaks | Fluid escape from heat exchanger, causing operational failures. | Worn seals, vibration fatigue, thermal cycling. | Regular inspections, use of quality seals, vibration dampening. |

| Inefficient Heat Transfer | Reduced thermal performance due to fouling. | Poor fluid flow, deposits on heat transfer surfaces. | Regular cleaning, optimized flow rates, use of high-efficiency designs. |

| Overheating | Excessive temperatures leading to system failures. | Blocked coolant pathways, pump failures. | Routine maintenance, flow monitoring, emergency shutdown systems. |

Marine heat exchangers play a crucial role in the efficient operation of nautical engines, transferring heat between fluids to regulate temperatures effectively. To ensure optimal performance and extend the lifespan of these essential components, it is vital to adhere to best maintenance practices. Regular inspections and cleaning are paramount. Marine environments expose heat exchangers to corrosive elements and fouling agents, which can significantly impede their efficiency.

**Tips: Inspect your heat exchanger at least once every six months to check for signs of corrosion or blockage.** Additionally, flushing the system and replacing worn-out components can prevent larger issues down the line. Pay attention to the fluid quality; using the right antifreeze and coolants can also greatly impact the heat exchanger's performance.

Another critical aspect of maintenance is monitoring temperature differentials. Consistent temperature readings can help identify potential problems early. **Tip: Keep a log of operational temperatures to track any unusual variations that may indicate issues.** Implementing proactive maintenance routines not only enhances reliability but also contributes to the longevity of marine heat exchangers, ensuring vessels operate smoothly in challenging conditions.

The design and development of marine heat exchangers are undergoing significant transformation with the incorporation of innovative technologies. Future trends highlight the growing role of applied AI and advanced computing, which are optimizing the efficiency of thermal management systems. According to a report from the International Maritime Organization, implementing AI-driven predictive maintenance can reduce operational downtime by up to 30%. This technological shift allows nautical engineers to enhance the lifespan and reliability of heat exchangers while minimizing energy loss.

In addition to AI, the exploration of advanced materials for thermal energy storage (TES) is paving the way for more sustainable marine operations. Emerging studies indicate that materials such as phase change materials (PCMs) and improved alloy compositions can significantly increase heat transfer efficiency, thereby supporting the integration of renewable energy sources on vessels. The Climate Adaptation Research and Innovation Framework underscores this necessity, emphasizing that adapting new technologies in marine heat exchangers is crucial for meeting both regulatory and environmental challenges. By investing in these advancements, the maritime industry can achieve greater resilience and efficiency in the face of climate change.