Leave Your Message

Understanding the performance and maintenance of inside heat exchangers is crucial for optimizing energy efficiency in various industrial processes. According to a recent report by the International Energy Agency, heat exchangers are responsible for nearly 30% of total energy consumption in industrial systems, highlighting their importance in energy management strategies. To maximize the operational efficiency of these systems, it is essential to implement effective maintenance practices and a thorough understanding of their performance characteristics.

Expert insights in this field indicate that regular maintenance and performance monitoring can significantly reduce operational costs. Dr. Jonathan Mitchell, a leading authority on thermal systems at the Heat Exchange Institute, states, "Investing in the regular assessment of inside heat exchangers not only prolongs their lifespan but also enhances overall process efficiency." This underscores the necessity for industry professionals to be equipped with essential tips and knowledge for maintaining and evaluating the performance of their inside heat exchangers. As the demand for energy efficiency continues to rise, mastering these components becomes increasingly vital to ensure sustainable industrial operations.

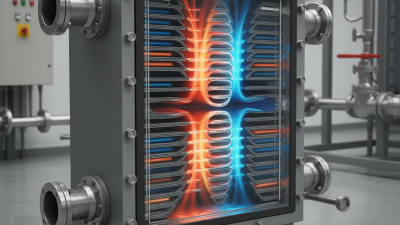

Inside heat exchangers play a pivotal role in various industrial applications, facilitating efficient heat transfer between two or more fluids. Understanding their basic operation is crucial for optimizing performance and ensuring longevity. Heat exchangers operate on principles of thermodynamics, where heat is transferred through conduction, convection, and sometimes radiation. According to a report by the Global Heat Exchanger Market, the efficiency of heat exchangers can achieve an effectiveness of up to 95%, making them indispensable in systems such as HVAC, refrigeration, and chemical processing.

A common challenge in maintaining inside heat exchangers is fouling, which can significantly reduce heat transfer efficiency. The Heat Transfer Research Institute estimates that fouling can diminish heat transfer rates by as much as 30% annually in poorly maintained systems. Regular maintenance practices, including cleaning and inspection, are essential to prevent such losses. Additionally, understanding the specific heat transfer coefficients for different fluids can aid in designing systems that maximize thermal efficiency while minimizing energy costs. By focusing on these foundational concepts, operators can enhance the performance of their heat exchangers and achieve substantial energy savings across their operations.

| Dimension | Description | Importance | Maintenance Frequency |

|---|---|---|---|

| Heat Transfer Area | The area available for heat exchange between fluids. | Critical for determining efficiency. | Annually |

| Flow Rate | The volume of fluid moving through the exchanger per unit of time. | Affects temperature difference and efficiency. | Monthly |

| Pressure Drop | The reduction in pressure of the fluids as they flow through the exchanger. | Indicates performance issues if excessive. | Quarterly |

| Temperature Approach | The difference in temperature between the fluids. | Essential for optimizing energy usage. | Semi-Annually |

| Material Condition | The physical state of the heat exchanger materials. | Ensures structural integrity and avoids leaks. | Annually |

Understanding the efficiency of inside heat exchangers hinges on key performance indicators (KPIs) that provide valuable insights into their operational effectiveness. One critical KPI is the overall heat transfer coefficient (U), which measures the heat transfer rate per unit area per degree of temperature difference. According to industry reports, maintaining an optimal U value is essential, as it directly impacts the energy consumption and operational costs of heat exchangers. A typical heat exchanger may experience a drop in efficiency by up to 20% when fouling occurs, emphasizing the need for regular monitoring of this KPI.

Another vital metric is the pressure drop across the heat exchanger, which indicates the resistance to fluid flow within the system. Excessive pressure drops can lead to increased energy consumption and reduced overall system efficiency. Industry studies suggest that maintaining a pressure drop below 10% of the inlet pressure is ideal for maximizing energy savings. Routine assessment of this KPI allows engineers to detect potential issues early and implement corrective measures promptly.

Tips for enhancing heat exchanger performance include implementing a regular cleaning schedule to minimize fouling and using temperature sensors to monitor real-time data on thermal efficiency. Additionally, employing advanced simulation software can help engineers optimize the design and operation of heat exchangers, ensuring that they operate at the highest possible efficiency levels while extending their lifespan. By focusing on these KPIs and implementing proactive maintenance strategies, organizations can significantly improve the reliability and efficiency of their heat exchangers.

Heat exchangers play a critical role in various industrial applications, yet their performance can be significantly hindered by several common issues. One prominent challenge is fouling, which can occur due to the accumulation of deposits on the heat transfer surfaces. According to a report from the American Society of Mechanical Engineers (ASME), fouling can reduce heat transfer efficiency by up to 30%, leading to increased energy consumption and operational costs. Regular maintenance, including cleaning protocols, can help mitigate these effects and maintain optimal efficiency.

Another key issue that can affect heat exchanger performance is corrosion. The National Association of Corrosion Engineers (NACE) estimates that corrosion in heat exchangers accounts for over $1 billion in annual maintenance costs across the industry. Implementing corrosion-resistant materials and protective coatings can significantly extend the lifespan of heat exchangers. Furthermore, monitoring fluid chemistry regularly can prevent corrosion-related failures, ensuring consistent performance.

**Tip:** Regularly inspect your heat exchangers for signs of fouling and corrosion to address potential issues before they escalate. Employing advanced monitoring technologies can provide real-time insights into the condition of your equipment, allowing for timely maintenance actions that can enhance performance and extend the service life of the heat exchanger. Additionally, employee training on the importance of maintenance protocols can empower teams to identify and resolve issues proactively, further reducing downtime and associated costs.

Regular maintenance of heat exchangers is crucial for maximizing their efficiency and extending their lifespan. Data from industry reports suggest that proper maintenance can enhance the operational efficiency of heat exchangers by as much as 20%. This is achieved through routine inspections and cleanings that prevent fouling and scaling, which are common issues that reduce the heat transfer efficiency. A study conducted by the Heat Exchange Institute indicates that 30% of heat exchanger failures can be traced back to inadequate maintenance practices. Therefore, implementing a comprehensive maintenance schedule can lead to significant cost savings in both repairs and energy consumption.

Additionally, monitoring the performance of heat exchangers through advanced diagnostic tools helps identify potential issues before they escalate. Regular thermal performance assessments, combined with pressure testing, can pinpoint areas requiring immediate attention, thus preventing unexpected downtimes. According to the American Society of Mechanical Engineers (ASME), performing preventive maintenance can reduce maintenance costs by up to 40%, as it allows for optimal operational performance while minimizing the risk of catastrophic failure. By adopting these essential maintenance practices, organizations can ensure their heat exchangers operate at peak efficiency and achieve a longer service life.

Troubleshooting heat exchanger problems can often feel overwhelming, but with a systematic approach, identifying and resolving issues becomes manageable. Start by monitoring the heat exchanger's performance metrics, such as temperature differentials and flow rates. A noticeable drop in performance can indicate fouling, scaling, or leaks. Regularly inspect for signs of corrosion or physical damage, as these are critical indicators of potential failures.

Tip 1: Always check the fluid quality being used in the heat exchanger. Contaminants or incorrect fluid characteristics can lead to premature wear and efficiency losses. Maintaining the right chemical balance and cleanliness of the fluids is vital for optimal performance.

When problems arise, employing pressure tests and thermal imaging tools can significantly aid in identifying leaks or inefficiencies that aren’t visible to the naked eye. Additionally, ensure that maintenance schedules are strictly adhered to; regular cleaning and inspections help in preemptively addressing issues before they escalate.

Tip 2: Document any changes or anomalies in operation. This record will provide valuable insights for troubleshooting recurring issues and can help in spotting trends that may indicate deeper systemic problems. Recognizing patterns over time facilitates more informed decision-making regarding repairs and upgrades.