Leave Your Message

Heat exchanger parts play a crucial role in determining the

energy efficiency of industrial applications, impacting both

operational costs and sustainability efforts. According to the U.S. Department of Energy, heat exchangers account for approximately

30% of the energy consumed in industrial processes, highlighting the significance

of optimizing their components. Research indicates that even minor enhancements in heat exchanger design can lead to energy

savings of 5% to 15% (ASHRAE, 2021). Furthermore, effective maintenance and

the selection of high-quality heat exchanger parts not only improve thermal performance but also extend equipment lifespan,

leading to reduced downtime and maintenance expenses. As industries increasingly prioritize energy efficiency amid rising energy

costs and regulatory pressures, understanding how heat exchanger parts influence overall system performance becomes essential

for achieving operational excellence.

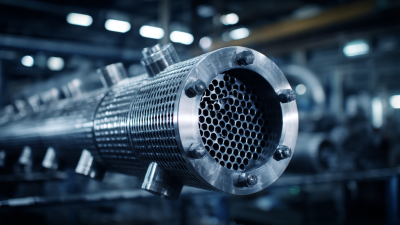

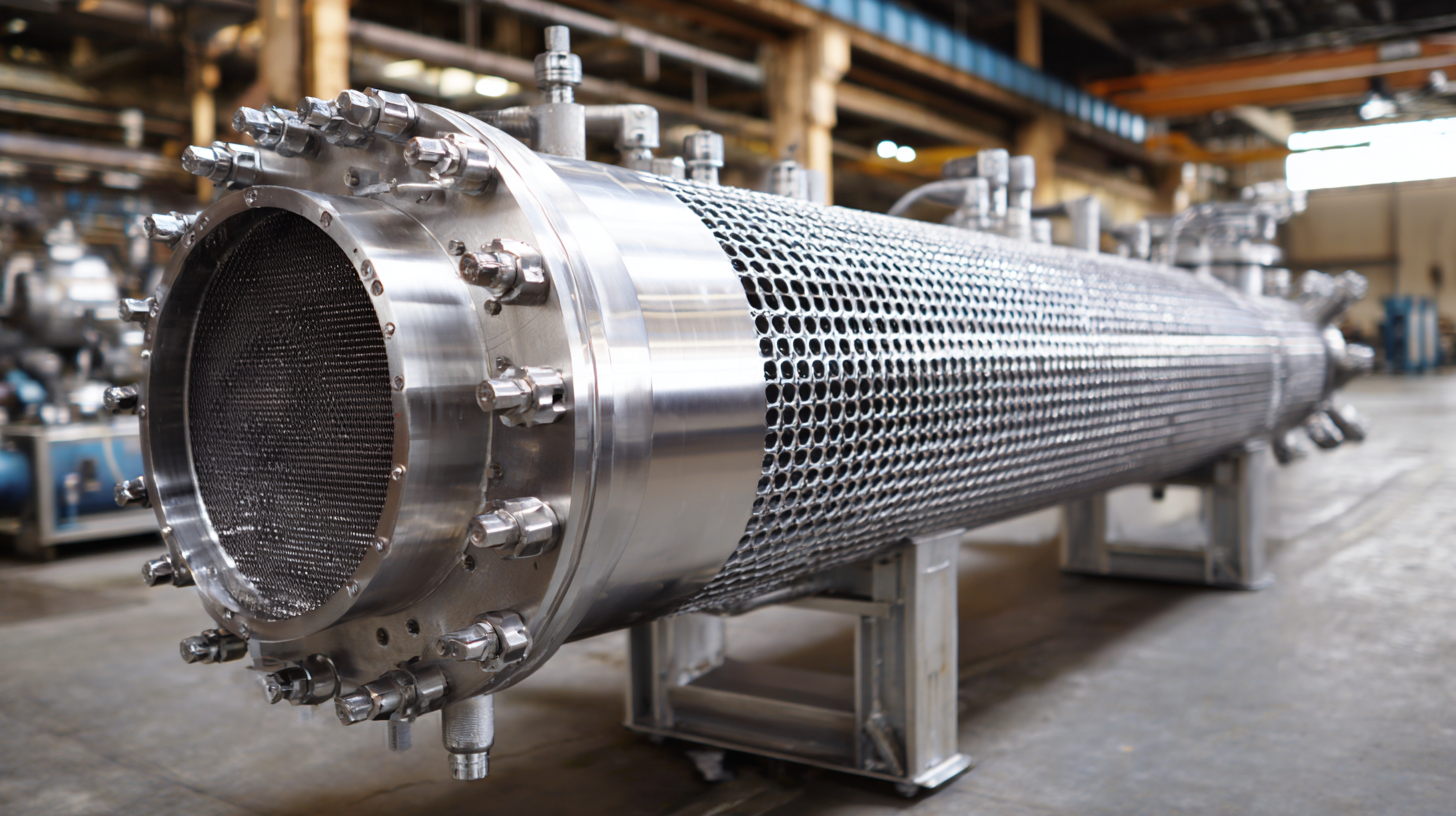

Heat exchangers play a pivotal role in optimizing energy efficiency in various industrial applications. Comprising essential parts such as tubes, fins, and plates, each component significantly contributes to the overall performance of the system. Tubes, for instance, are designed to facilitate heat transfer between two fluids, minimizing thermal resistance and ensuring maximum energy recovery. Fins increase the surface area for heat exchange, thus enhancing the heat transfer rate. Understanding the specific functions of these components is crucial for identifying how modifications or upgrades can lead to substantial energy savings.

Moreover, the design and material selection of heat exchanger parts are vital for their efficacy. Choosing materials with high thermal conductivity can enhance the heat exchanger's efficiency, while the geometry of components can lead to better flow distribution and reduced pressure drops. By focusing on the functionality of these parts, industries can implement tailored solutions that not only improve energy efficiency but also prolong the lifespan of the heat exchangers. Consequently, a deeper comprehension of how these components interact within the system fosters better design strategies and operational practices aimed at energy conservation.

| Part Name | Functionality | Material | Impact on Energy Efficiency | Recommended Maintenance |

|---|---|---|---|---|

| Heat Exchanger Tubes | Facilitate heat transfer between fluids | Stainless Steel | High thermal conductivity improves efficiency | Regular cleaning to prevent fouling |

| End Caps | Seal the heat exchanger | Carbon Steel | Ensures pressure retention, affecting performance | Inspect for leaks regularly |

| Baffles | Direct flow for efficient heat transfer | Aluminum | Improves thermal performance by enhancing fluid turbulence | Check for corrosion and damage |

| Plates (for Plate Heat Exchangers) | Maximize surface area for heat transfer | Titanium or Stainless Steel | Increased efficiency due to higher surface area | Routine inspections for scaling |

| Expansion Joints | Accommodate thermal expansion | Flexible Materials | Prevents mechanical stress, maintaining efficiency | Inspect for wear and tear periodically |

The materials used in heat exchanger components play a crucial role in determining the overall energy efficiency of industrial applications. Selecting the right materials can minimize thermal resistance and enhance heat transfer capabilities. For instance, metals with high thermal conductivity, such as copper and aluminum, are often preferred for their ability to conduct heat effectively. In contrast, materials like stainless steel, while resistant to corrosion, may exhibit lower thermal performance if not properly designed. Understanding the specific needs of a process, including temperature fluctuations and fluid characteristics, can guide material selection to optimize performance.

Moreover, the structural integrity and longevity of heat exchanger parts directly influence operational efficiency. For example, the choice of material affects not just thermal performance but also resistance to fouling, scaling, and erosion. Using specialized coatings or advanced alloys can prevent degradation over time, thereby maintaining efficiency and reducing maintenance costs. Ultimately, evaluating the role of materials in heat exchanger design is essential for enhancing energy utilization and achieving sustainable industrial operations. By prioritizing material properties that align with operational demands, industries can significantly improve both performance and profitability.

Heat exchangers are critical components in various industrial applications, and their design significantly influences energy efficiency. A study by the U.S. Department of Energy highlighted that optimized heat exchanger configurations can enhance thermal performance by up to 20%. This improvement is largely attributed to advancements in design, such as the use of compact heat exchangers that increase the surface area for heat transfer while occupying less space. By employing turbulators and specialized fin arrangements, these designs can maximize contact between fluids, promoting more efficient thermal exchange.

Moreover, the configuration of heat exchangers also plays a vital role in pressure drop characteristics, which can affect overall system efficiency. Research from the International Journal of Thermal Sciences indicates that improper design can lead to excessive pressure drops, reducing the energy efficiency of the system by as much as 15%. By carefully analyzing flow paths and optimizing geometry, engineers can mitigate these losses. Therefore, understanding the interplay between heat exchanger design and its energy performance is essential for companies aiming to enhance operational efficiency and reduce energy costs in their industrial processes.

Maintenance practices play a crucial role in ensuring the energy efficiency of heat exchangers in industrial applications. Regular inspections and timely maintenance can significantly reduce energy waste. Properly maintained heat exchangers operate more efficiently, as they can effectively transfer heat without the losses associated with fouling and wear. For instance, routine cleaning of heat transfer surfaces can remove deposits that inhibit heat transfer, thus enhancing overall system performance.

Tips for Effective Maintenance:

- Schedule Regular Inspections: Conduct assessments at appropriate intervals to identify potential issues before they escalate.

- Implement Cleaning Protocols: Use chemical cleaning solutions or mechanical methods as necessary to keep heat exchanger surfaces clear of fouling.

- Monitor Performance: Keep track of key performance indicators to detect deviations from expected energy usage, allowing for prompt corrective actions.

Investing in maintenance will not only extend the lifespan of heat exchangers but also contribute to lowering operational costs through improved energy efficiency. Ensuring that maintenance staff is well-trained to identify and rectify issues can enhance performance and reliability, ultimately leading to a more sustainable industrial operation.

Innovations in heat exchanger technology have significantly reshaped industrial energy use, leading to improved efficiency and reduced operational costs. Recent studies indicate that advanced heat exchange materials, such as graphene and enhanced surface designs, can boost thermal performance by over 30% compared to traditional designs. For instance, the U.S. Department of Energy reports that optimizing heat exchanger efficiency could save U.S. industries approximately $2 billion annually in energy costs, underlining the critical role these components play in energy management.

One groundbreaking development is the rise of compact heat exchangers, which require less space while providing higher energy transfer rates. These innovations not only minimize energy consumption but also streamline processes, leading to a more sustainable production environment. Moreover, integrating smart sensors in heat exchanger systems allows for real-time monitoring and predictive maintenance, reducing downtime and enhancing energy savings.

**Tip:** When selecting heat exchanger technology, consider not only the initial costs but also the long-term energy savings and maintenance benefits. Investing in advanced materials and smart technology can yield substantial returns over the equipment's lifecycle. Always consult with industry experts to choose solutions tailored to specific operational needs for optimal performance.

This chart illustrates the effectiveness of different heat exchanger components in improving energy efficiency across various industrial applications. The data indicates the percentage improvement in energy use attributed to innovations in heat exchanger technology.