Leave Your Message

In today's rapidly evolving industrial landscape, energy efficiency has become a critical focus for businesses seeking to optimize their operations and reduce costs. One of the key solutions to achieving efficient energy transfer is the implementation of a Heating Plate Heat Exchanger. According to Dr. Emily Carter, a leading expert in thermal energy systems, "The Heating Plate Heat Exchanger is not just a component; it’s a vital ingredient for any system aiming for high efficiency and sustainability."

The Heating Plate Heat Exchanger plays an essential role in various applications by facilitating the effective transfer of heat between two fluids, minimizing energy loss and enhancing overall performance. As industries become increasingly aware of their carbon footprint, the importance of such advanced technologies cannot be overstated. It allows facilities to reclaim and reuse heat that would otherwise be wasted, thus promoting a more sustainable approach to energy consumption.

By prioritizing the utilization of a Heating Plate Heat Exchanger, companies can ensure that they are not only meeting their operational demands but are also taking part in a greater movement towards responsible and efficient energy practices. With professionals like Dr. Carter advocating for its widespread adoption, it's clear that the future of energy transfer rests significantly on the capabilities of the Heating Plate Heat Exchanger.

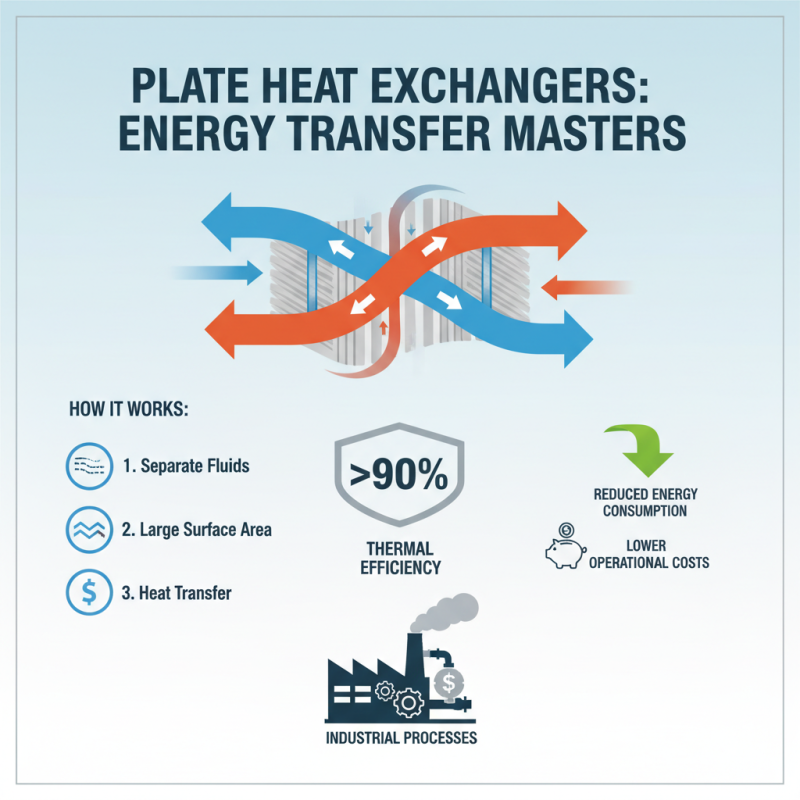

Heating plate heat exchangers are crucial in facilitating efficient energy transfer within various industrial processes. These devices utilize a series of plates to separate two fluids, allowing one fluid to transfer heat to the other without mixing. The structure of the plates increases the surface area for heat exchange, enhancing thermal efficiency. According to industry reports, effective heat exchangers can achieve thermal efficiencies exceeding 90%, significantly reducing energy consumption and operational costs for businesses.

When selecting a heating plate heat exchanger, it's essential to consider key factors such as the materials used and the specific application requirements. For instance, stainless steel is often chosen for its durability and resistance to corrosion, making it ideal for harsh environments. Furthermore, maintaining optimal flow rates can maximize heat transfer efficiency.

**Tips:** To improve the lifespan of your heat exchanger, regular maintenance is vital. This includes checking for blockages and verifying the integrity of the plates. Additionally, implementing a monitoring system can help detect any inefficiencies early on. This proactive approach can prevent costly downtimes and ensure that your processes run smoothly.

Heating plate heat exchangers are essential components for enhancing energy efficiency in various industrial applications. One of their primary benefits is their ability to facilitate efficient thermal transfer, which can significantly reduce energy consumption. According to the U.S. Department of Energy, optimizing heat transfer processes can save up to 30% in energy costs, thereby providing a quick return on investment. This efficiency is achieved through the design of plate heat exchangers, which offer a large surface area for heat exchange while minimizing the volume of the system, ensuring more effective heat transfer without excessive energy input.

Moreover, the compact design of heating plate heat exchangers allows for flexible installation and reduced footprint, which is particularly beneficial in facilities with space constraints. Industry reports indicate that the use of these exchangers can lead to improvements in process reliability and a decrease in maintenance costs by up to 15%, as their design minimizes fouling and enhances durability. As industries strive to meet sustainability targets, the adoption of heating plate heat exchangers not only contributes to lower greenhouse gas emissions but also aligns with the growing demand for energy-efficient technologies in manufacturing and processing sectors.

Heating plate heat exchangers are widely utilized across various industries due to their ability to optimize energy transfer processes. In the food and beverage industry, these heat exchangers play a crucial role in pasteurization and sterilization. They ensure that products are safely heated to eliminate harmful microorganisms while preserving taste and nutritional value. The efficient heat transfer capability of heating plates allows for rapid heating and cooling cycles, which is essential for maintaining product quality and extending shelf life.

In the chemical processing sector, heating plate heat exchangers are essential for various reaction processes, enabling precise temperature control. They facilitate the efficient heating of reactants to optimal reaction temperatures, thus enhancing reaction rates and overall productivity. Additionally, in the HVAC industry, these exchangers are employed for space heating and cooling systems, providing energy-efficient solutions for regulating indoor temperatures. Their compact design and high efficiency contribute to reduced energy consumption, aligning with the growing demand for sustainable practices in industrial operations.

When choosing a heating plate heat exchanger, several key factors must be considered to ensure efficient energy transfer and operational effectiveness. One of the primary factors is the design and material of the heat exchanger. According to a report by the International Energy Agency, heat exchangers made from stainless steel can provide better corrosion resistance and durability, which is essential in applications where fluid compatibility is crucial. This choice offers long-term savings through reduced maintenance costs and increased operational lifespan.

Another significant factor is the thermal performance specifications, particularly the overall heat transfer coefficient (U-value). Selecting a heat exchanger with a higher U-value can significantly improve energy efficiency by maximizing the heat transfer between the fluids involved. A study published in the Journal of Heat Transfer Engineering shows that optimizing the design for specific applications can lead to energy savings of up to 30%. Furthermore, considerations about flow arrangement—whether counterflow or parallel flow—can impact the efficiency of heat exchange. Counterflow arrangements typically provide superior thermal performance, enabling better temperature gradients and enhanced heat recovery capabilities.

Lastly, the sizing and flow rates of the fluids are critical in ensuring the heat exchanger operates within its designed capacity. Proper hydraulic design can prevent issues such as fouling or scaling, which may hinder performance over time. Understanding the specific requirements of your process—such as required temperature differences and pressure drops—will guide the selection of an appropriate heating plate heat exchanger, contributing to an overall efficient energy transfer system.

Proper maintenance of a heating plate heat exchanger is crucial for ensuring its optimal performance and longevity. Regular inspections play a significant role in identifying early signs of wear or damage. Check for any leaks, corrosion, or fouling that may affect the efficiency of heat transfer. Cleaning the plates periodically helps remove any accumulated debris or deposits, which can impede fluid flow and reduce heat exchange effectiveness. Implementing a routine maintenance schedule will not only enhance performance but also minimize the risk of unexpected breakdowns.

Another vital aspect of maintenance is monitoring the operational parameters of the heat exchanger. Keeping track of temperature differentials and flow rates can provide insights into the system's efficiency. Any significant deviations from the norm may indicate underlying issues that need to be addressed promptly. Additionally, ensuring that all seals and gaskets are in good condition will prevent leakage and maintain the integrity of the system. By following these maintenance tips, you can maximize the efficiency of your heating plate heat exchanger and ensure it operates reliably over time.

| Maintenance Tips | Frequency | Recommended Actions | Impact on Performance |

|---|---|---|---|

| Inspect for leaks | Monthly | Check joints and seals | Prevents energy loss |

| Clean surfaces | Quarterly | Remove dirt and deposits | Enhances heat transfer efficiency |

| Monitor fluid levels | Bi-weekly | Top-up as necessary | Maintains optimal operation |

| Check temperature and pressure | Weekly | Record readings | Ensures system is within specification |

| Inspect insulation | Annually | Replace damaged insulation | Reduces heat loss |