Leave Your Message

In the ever-evolving field of thermal management, the efficiency of Heating Plate Heat Exchangers is paramount for optimizing energy consumption and ensuring sustainable operations. According to the U.S. Department of Energy, heating systems that leverage advanced heat exchanger technologies can enhance thermal efficiency by up to 30% compared to conventional systems. Furthermore, a recent report by the International Energy Agency indicates that improving heat exchange efficiency could significantly reduce greenhouse gas emissions in industrial processes, aligning with global sustainability goals. As industries continue to seek competitive advantages and adhere to stricter environmental regulations, evaluating the performance of Heating Plate Heat Exchangers becomes crucial. This blog aims to provide an essential checklist to assess their efficiency, helping engineers and facility managers make informed decisions that will lead to improved performance and energy savings.

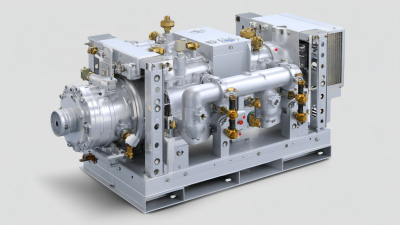

Heating plate heat exchangers are vital components in various industrial applications, facilitating efficient thermal transfer between two fluids. Understanding their basic functionality is crucial for optimizing their performance. These heat exchangers operate by passing one fluid through a series of plates, allowing heat to be transferred to another fluid flowing on the opposite side of the plates. The design of the plates can impact the overall efficiency and effectiveness of heat transfer, making it essential to analyze factors such as plate material, arrangement, and surface area.

The efficiency of heating plate heat exchangers is influenced by several key factors, including flow rates and temperature differentials. By carefully managing these elements, operators can achieve optimal performance. Regular monitoring and maintenance are also critical, as fouling and surface degradation can severely reduce the heat exchanger’s efficiency over time. Understanding these basic principles empowers engineers and technicians to make informed decisions to enhance system performance and energy conservation in thermal processing applications.

Evaluating the efficiency of heat exchangers is crucial in various applications, from industrial processing to environmental technology. Key performance indicators (KPIs) serve as benchmarks for measuring this efficiency. These indicators can include parameters such as thermal effectiveness, pressure drop, and overall heat transfer coefficient. Recent advancements in multiphysics analysis and the incorporation of innovative fluid dynamics, such as hyperbolic-cut twisted tape inserts and graphene oxide nanofluids, can significantly enhance thermal performance. Such approaches allow for the optimization of heat exchanger designs under turbulent conditions, ensuring superior energy transfer and efficiency.

Moreover, effective integration of waste heat recovery systems is vital in the quest for sustainable energy solutions. Techniques that analyze gas diffusion layers and various structural modifications not only improve performance but also contribute to energy conservation across applications. Understanding and implementing these KPIs ensure that systems like the shell-and-tube latent heat storage units are maximized for performance. This holistic approach reflects the industry's commitment to developing more efficient thermal systems, drawing from cutting-edge technologies and innovative designs to tackle ongoing energy challenges.

When it comes to the performance of heating plate heat exchangers, several common issues can significantly impact their efficiency. One major concern is fouling, where unwanted deposits accumulate on the heat transfer surfaces. This buildup can reduce the heat transfer area, leading to decreased thermal efficiency and increased energy consumption. Regular inspections and cleanings are crucial to mitigate fouling, ensuring optimal operation and prolonging the lifespan of the equipment.

Another issue affecting performance is improper flow distribution. If the fluid does not flow evenly across the plates, certain areas may experience overheating, while others remain underutilized. This uneven distribution can lead to hot spots and accelerated wear, ultimately affecting the reliability of the heat exchanger. Implementing flow distribution devices or redesigning the system layout can help ensure more uniform flow and enhance overall performance.

Finally, insufficient maintenance practices can result in diminished efficiency over time. Neglecting to monitor key parameters such as pressure drops, temperature variations, and leakages may lead to larger issues that are costly to address. Establishing a routine maintenance schedule allows for early detection of problems, ensuring that the heating plate heat exchangers function at their best, maintaining energy efficiency and saving on operational costs.

When evaluating the efficiency of heating plate heat exchangers, maintenance and optimization practices play a crucial role. Regular inspections, cleaning, and appropriate monitoring of temperature and pressure differentials can significantly enhance performance. According to industry reports, effective maintenance strategies can lead to an increase in operational efficiency by up to 30%. This not only extends the lifespan of the equipment but also reduces energy consumption, which is a key factor in increasing cost-effectiveness.

The global market for brazed aluminum heat exchangers (BAHX) is projected to experience robust growth, with estimates suggesting an increase from $110.38 million in 2025 to $770.3 million by 2033, reflecting a steady compound annual growth rate (CAGR) of 4.6%. This growth can be attributed to rising demand in various sectors, including HVAC, refrigeration, and industrial processes. Optimizing heat exchanger performance by implementing advanced technologies such as intelligent control systems can further capitalize on this market growth, enabling industries to meet evolving energy standards while maximizing efficiency.

This bar chart illustrates the efficiency metrics of various heating plate heat exchangers based on different parameters including temperature differential (ΔT), flow rate, and overall heat transfer coefficient (U). Monitoring these factors is essential for effective maintenance and optimization.

In the realm of thermal management, heating plate heat exchangers have proven their worth through multiple real-world applications. One notable success story involves a heating plate heat exchanger installed in a manufacturing facility that faced significant energy wastage. By optimizing the heat transfer process, the facility was able to reduce energy consumption by 30%, leading to substantial cost savings and a notable decrease in environmental impact.

**Tip 1:** Regular maintenance and cleaning of heat exchangers can drastically improve efficiency. Accumulation of dirt and scale can impede heat transfer, so ensuring your equipment is clean will help maintain peak performance.

Another compelling case comes from the food processing industry, where precise temperature control is vital. By integrating advanced sensors and control systems, one company was able to enhance their heat exchanger's efficiency by 25%. This improvement not only ensured product quality but also extended the lifespan of the equipment.

**Tip 2:** Invest in the right materials and design tailored for your application. The choice of materials can influence both the efficiency and durability of heat exchangers, so conducting thorough research before installation is essential.

Through these real-world examples, it's evident that evaluating and enhancing heat exchanger efficiency can lead to valuable gains in both energy savings and operational effectiveness.

| Parameter | Value | Unit | Remarks |

|---|---|---|---|

| Heat Transfer Coefficient | 450 | W/m²K | Optimized through design improvements |

| Pressure Drop | 5 | kPa | Minimal impact on system |

| Overall Efficiency | 85 | % | Achieved through maintenance |

| Operating Temperature | 150 | °C | Stable under current conditions |

| Fluid Velocity | 1.5 | m/s | Considered optimal for heat exchange |