Leave Your Message

In the realm of industrial applications, the performance of heat exchangers plays a pivotal role in optimizing energy efficiency, safety, and operational costs. A recent study by the International Energy Agency (IEA) highlights that inefficient heat exchanger systems can lead to energy losses upwards of 30%, underscoring the necessity for meticulous attention to heat exchanger parts. Factors such as fouling, corrosion, and improper material selection can critically impair functionality, ultimately elevating maintenance costs by nearly 25%. Understanding these issues is essential for engineers and operators aiming to enhance the longevity and efficiency of their systems.

By addressing the myriad challenges associated with heat exchanger parts, industries can not only mitigate financial losses but also contribute to sustainable energy practices, aiding in global efforts to reduce carbon footprints.

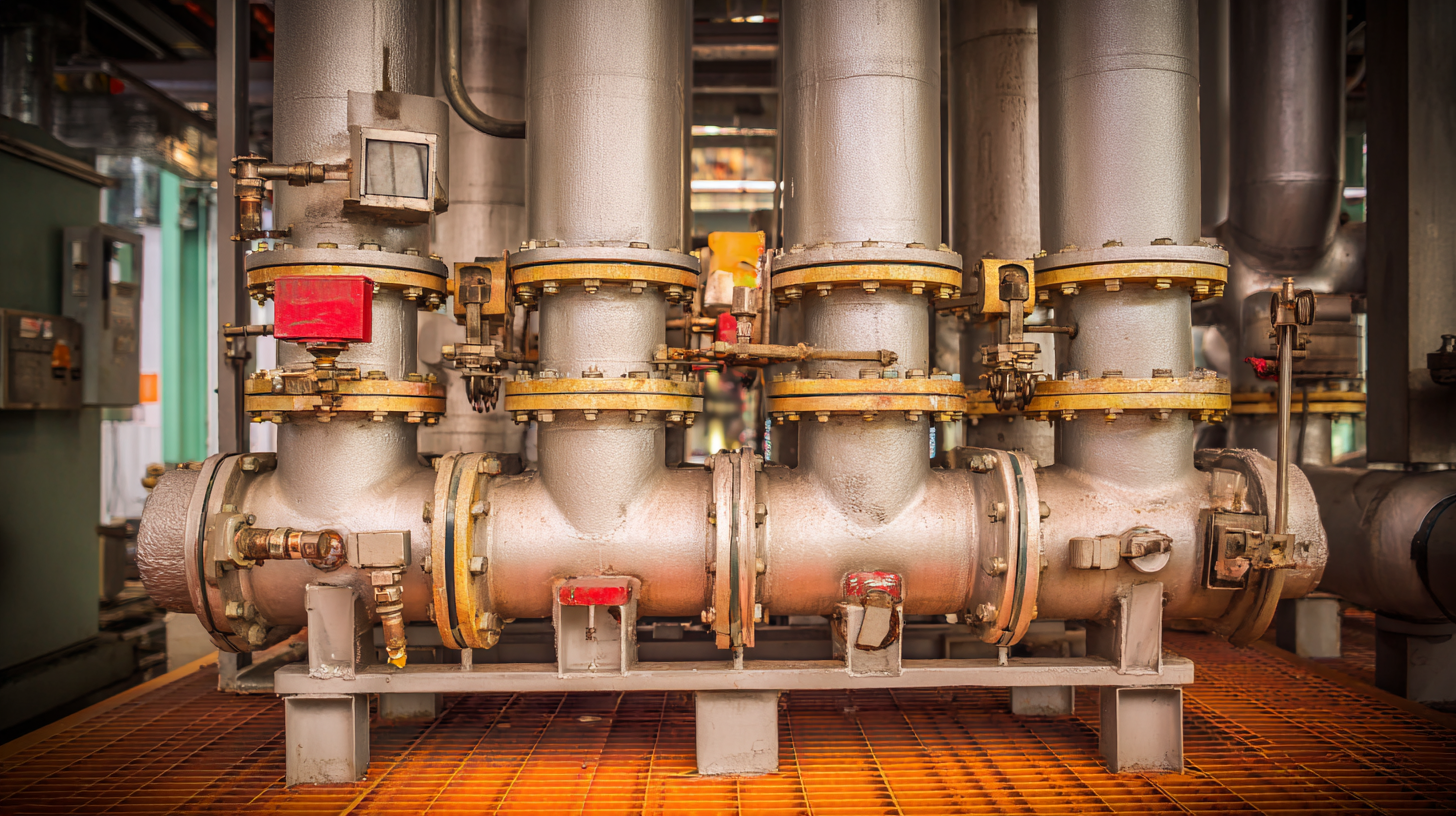

Heat exchangers are critical components in various industrial processes, yet their efficiency can be significantly compromised by component failures. According to a report by the Global Heat Exchanger Market, about 30% of all heat exchanger failures are attributed to fouling, where unwanted materials accumulate on the heat transfer surfaces, reducing thermal efficiency by up to 50%. This accumulation not only leads to energy wastage but also increases operational costs as the system requires more energy to achieve the desired temperature exchange.

Heat exchangers are critical components in various industrial processes, yet their efficiency can be significantly compromised by component failures. According to a report by the Global Heat Exchanger Market, about 30% of all heat exchanger failures are attributed to fouling, where unwanted materials accumulate on the heat transfer surfaces, reducing thermal efficiency by up to 50%. This accumulation not only leads to energy wastage but also increases operational costs as the system requires more energy to achieve the desired temperature exchange.

Another notable failure mode is corrosion, which can decrease the lifespan of heat exchanger parts dramatically. The National Association of Corrosion Engineers (NACE) estimates that corrosive damage in heat exchangers costs industries billions annually, with studies suggesting that maintenance and replacement costs can be reduced by up to 25% through regular monitoring and early intervention. Corrosion can lead to leaks, further diminishing performance and potentially leading to shutdowns that disrupt operations. Understanding these common component failures is essential for maintaining optimal efficiency and extending the operational lifespan of heat exchangers.

Gaskets and seals are critical components in heat exchangers, significantly influencing their efficiency and overall performance. According to a report by the Heat Exchanger World, issues with gaskets and seals can lead to a reduction in heat transfer efficiency by up to 25%. This loss is primarily due to leaks that occur when these components fail, allowing fluids to bypass the intended heat exchange process. The integrity of gaskets and seals is paramount in maintaining optimal thermal conductivity within heat exchangers, as even the slightest degradation can disrupt fluid flow and thermal barriers.

Moreover, the type of material used for gaskets and seals plays a vital role in their effectiveness. The American Society of Mechanical Engineers (ASME) emphasizes that selecting materials that can withstand high temperatures and corrosive environments is essential. For instance, high-performance elastomers or metal gaskets are preferable in applications facing extreme operational conditions. When properly designed and maintained, these components ensure a reliable seal, facilitating efficient heat transfer and improving the lifespan of heat exchanger systems. Regular inspection and timely replacement of gaskets and seals can prevent performance issues and maintain the overall integrity of the heat exchange process.

Corrosion is one of the primary factors that significantly impacts the performance and longevity of heat exchangers. According to a report by the National Association of Corrosion Engineers (NACE), corrosion-related failures can lead to up to 25% of heat exchanger operational downtime. This not only affects efficiency but also leads to increased maintenance costs and unexpected shutdowns, disrupting production processes. The types of corrosion most commonly encountered in heat exchangers include Pitting, Galvanic Corrosion, and Stress Corrosion Cracking, each posing unique challenges depending on the materials used and operating conditions.

The financial implications of corrosion are staggering. Studies indicate that the cost of corrosion in piping and heat exchangers can exceed $8 billion annually in the U.S. alone. Advanced materials and protective coatings are essential to mitigate these issues; for instance, using duplex stainless steels or applying epoxy coatings can enhance resistance against aggressive environments. Furthermore, regular maintenance and monitoring are crucial, as implementing predictive maintenance technologies can reduce corrosion-related failures by up to 40%, significantly extending the lifespan of heat exchangers and optimizing their performance in various industrial applications.

Fouling is a significant challenge in heat exchanger systems, particularly in applications like dairy processing where milk can leave residues that disrupt heat transfer efficiency. A recent dynamic 2D model has been developed to optimize milk thermal treatment, integrating the complexities of fouling and cleaning processes. This model allows operators to better predict and manage the fouling behavior of plate heat exchangers, ultimately leading to improved thermal performance and reduced downtime due to cleaning operations.

Addressing fouling involves understanding its mechanisms, often categorized into inorganic scaling and organic deposits. Continuous study and innovation, such as the introduction of self-cleaning systems, are critical for enhancing operational reliability. By employing advanced technologies that automate the cleaning process, facilities can minimize the impact of fouling on their performance, ensuring that energy consumption is optimized and waste is reduced. Therefore, focusing on effective fouling management not only enhances the efficiency of heat exchangers but also contributes to more sustainable industrial practices.

Material selection is a crucial aspect of heat exchanger design that significantly impacts performance, durability, and efficiency. According to the "Heat Exchanger Market Report 2021" by Allied Market Research, the global heat exchanger market was valued at approximately $15 billion in 2020 and is projected to reach $24 billion by 2027, driven largely by advancements in material technology. The right materials not only enhance thermal conductivity but also improve resistance to corrosion, fouling, and thermal fatigue. For instance, copper and its alloys are often favored for their excellent thermal conductivity, which can be as high as 400 W/m∙K, while stainless steel is commonly used for its resistance to corrosion in harsh environments.

Furthermore, the performance of heat exchangers can be severely compromised by improper material choices under specific operational conditions. The "Journal of Heat Transfer" reports that failures in heat exchangers due to material degradation account for around 25% of overall maintenance costs in industrial settings. By selecting materials that align with the operational temperatures, pressures, and fluid chemistries, designers can create heat exchangers that not only operate efficiently but also have extended lifespans, potentially reducing maintenance frequency and costs. Hence, careful consideration of material properties is vital for maximizing heat exchanger performance and reliability.

Understanding the Importance of Material Selection in Heat Exchanger Design

| Component | Material | Issue | Impact on Performance | Recommendation |

|---|---|---|---|---|

| Heat Exchanger Tubes | Stainless Steel | Corrosion | Reduces heat transfer efficiency | Use corrosion-resistant coatings |

| End Plates | Carbon Steel | Structural Weakness | Leads to leaks and loss of pressure | Consider using high-strength alloys |

| Gaskets | PTFE | Thermal Degradation | Can cause fluid leaks | Select materials with higher thermal stability |

| Baffles | Aluminum | Erosion | Affects flow distribution | Use thicker or harder materials |