Leave Your Message

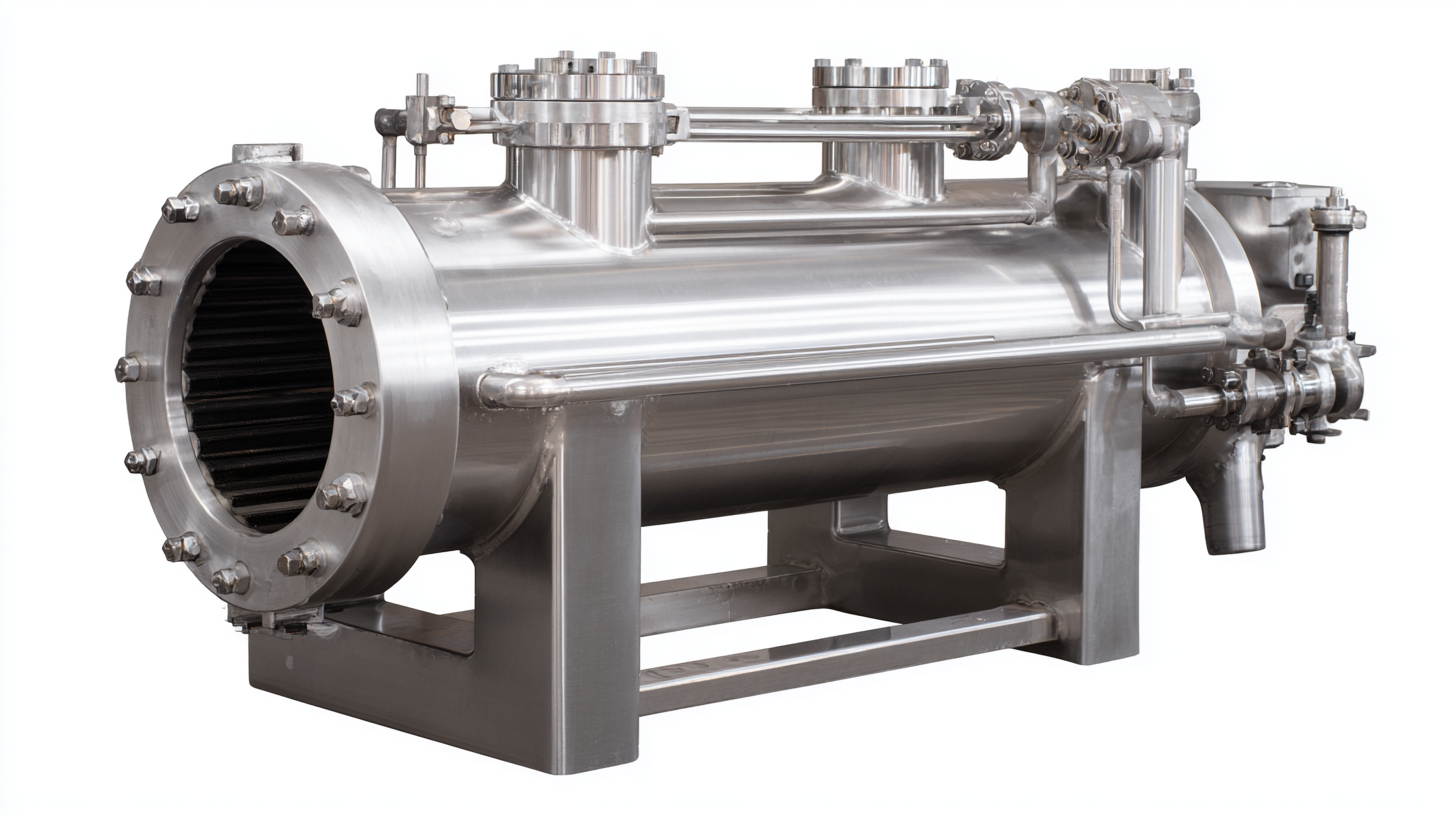

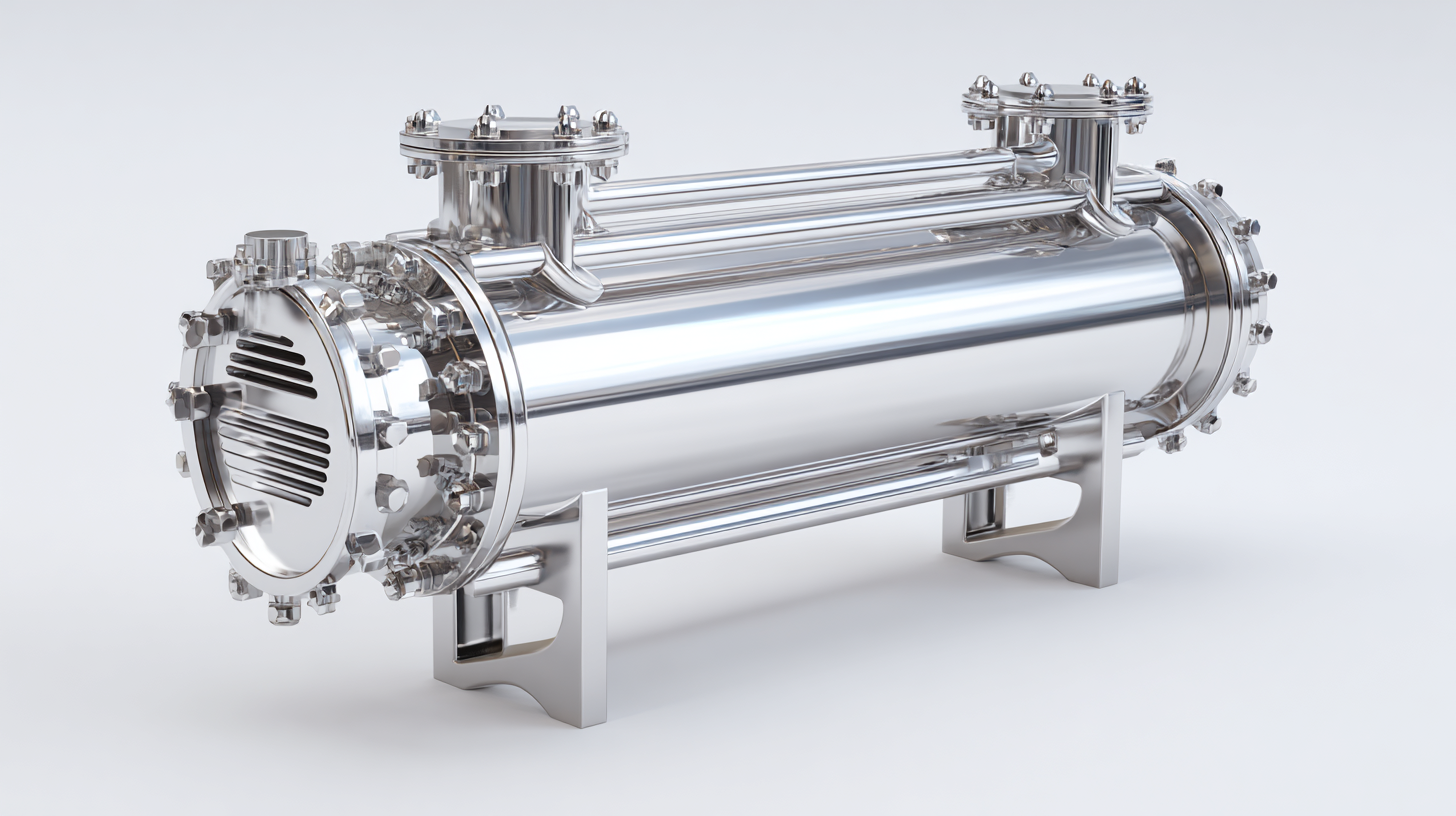

In the ever-evolving world of food processing, efficiency and innovation are paramount to meet the growing demands of consumers while maintaining high-quality standards. One of the key components that significantly enhances the efficiency of food processing operations is the Food Heat Exchangers. These ingenious systems play a crucial role in transferring heat between different substances, thereby improving energy efficiency and product quality. This ultimate guide delves into the seven essential advantages of Food Heat Exchangers, exploring how they contribute to energy savings, better temperature control, and optimized production processes. By understanding these benefits, food manufacturers can leverage the power of Food Heat Exchangers to streamline their operations, reduce operational costs, and ultimately, deliver superior products to the market.

In the food processing industry, energy efficiency is a crucial factor that can significantly impact both operational costs and environmental sustainability. Food heat exchangers play a vital role in achieving enhanced energy efficiency. These systems are designed to transfer heat between two or more fluids without mixing them, allowing manufacturers to reuse energy that would otherwise be lost. This process not only reduces energy consumption but also optimizes the overall processing time, resulting in a more streamlined production line.

Moreover, the implementation of efficient heat exchangers can lead to substantial cost savings. By recovering waste heat and utilizing it for various applications, food processors can minimize their reliance on additional energy sources. This not only lowers energy bills but also contributes to a reduced carbon footprint, aligning with global sustainability goals. As food manufacturers continue to seek innovative ways to improve efficiency and reduce costs, investing in high-performance heat exchangers proves to be a strategic move that benefits both the bottom line and the environment.

Food waste is a significant issue in today's culinary and processing industries. By leveraging food heat exchangers, businesses can optimize heat exchange processes, leading to a substantial reduction in food waste. These systems are designed to recover and reuse heat, which not only enhances energy efficiency but also minimizes the thermal damage to food products. This careful management of temperatures helps maintain the quality and safety of food items, reducing the likelihood of spoilage.

One effective tip for maximizing the benefits of food heat exchangers is to regularly monitor and adjust the temperature settings based on the specific requirements of different food types. For example, delicate items like dairy products require gentler heating compared to heartier vegetables. Additionally, implementing real-time temperature tracking can help identify any deviations that might lead to quality loss, allowing for timely interventions.

Another strategic approach is to schedule maintenance checks for the heat exchangers. Regular inspections and upkeep ensure that the systems operate at peak efficiency. This not only prolongs the lifespan of the equipment but also safeguards against potential heat losses that could result in increased waste. Investing in employee training on proper operational practices can further enhance the effectiveness of heat exchangers, ensuring all staff are aligned on best practices for reducing food waste.

In the evolving landscape of food processing, the integration of advanced heat exchange technology has emerged as a pivotal factor in enhancing product quality and consistency. Food heat exchangers play a critical role in maintaining optimal temperatures during processing, which helps preserve the nutritional and sensory attributes of food products. This is especially important in processes that require precise temperature control to ensure that flavors, textures, and nutritional values are retained. By effectively managing heat transfer, these systems enable manufacturers to produce consistent products that meet consumer expectations and regulatory standards.

Furthermore, the adoption of innovative techniques akin to those in biomanufacturing highlights the industry's shift towards more efficient and streamlined processes. Just as single-use bioreactors reduce contamination risks and improve biomolecule synthesis, modern heat exchangers minimize the risk of cross-contamination in food processing. This synergy of technologies not only leads to improved efficiency but also supports the industry's commitment to sustainability. As the demand for high-quality food products continues to rise, leveraging advanced heat transfer solutions will be essential for ensuring consistency and excellence in the marketplace.

Food heat exchangers play a crucial role in minimizing the environmental impact of food processing. By efficiently transferring heat between two fluids, these systems optimize energy consumption and reduce waste. Traditional heating methods often lead to significant energy loss, but heat exchangers recapture and reuse energy, which is vital in an industry that strives for sustainability. This not only lowers operating costs but also helps in meeting regulatory requirements regarding energy use and emissions.

Moreover, food heat exchangers support sustainable practices by enhancing product quality and safety. By maintaining precise temperature control, they ensure that food retains its nutritional value while minimizing spoilage and waste. This meticulous handling of food products translates to less food loss and a lower carbon footprint. Additionally, many modern heat exchangers are designed to use eco-friendly materials, further contributing to sustainability. In a time when environmental concerns are paramount, the adoption of heat exchangers in food processing embodies a commitment to a greener future, aligning industry practices with global sustainability goals.

Implementing food heat exchangers offers significant cost savings over time, making them a vital investment for the food processing industry. These systems operate by transferring heat between materials without direct contact, allowing processors to utilize energy more efficiently. By recovering waste heat, manufacturers can lower their overall energy consumption, which inherently reduces utility costs. This energy efficiency translates directly into a stronger bottom line, enabling companies to allocate resources to other critical areas such as research and development or workforce training.

Moreover, the financial implications extend beyond immediate energy savings. Heat exchangers can improve product quality and consistency, which enhances customer satisfaction and loyalty. Consistency in processing also minimizes waste due to spoilage or inefficiencies, further driving overall cost reductions. With a lower operational risk and enhanced product yield, businesses can experience not only higher profit margins but also a quicker return on investment. As heat exchanger technology continues to evolve, the long-term financial benefits will only increase, positioning companies for lasting success in a competitive marketplace.