Leave Your Message

The growing emphasis on energy efficiency in industrial processes necessitates innovative solutions to optimize thermal management. Plate To Plate Heat Exchangers have emerged as a critical technology in this pursuit, enabling superior heat transfer and minimizing energy losses. According to the U.S. Department of Energy, enhancing energy efficiency in industrial settings could lead to a reduction of up to 30% in energy consumption, translating into substantial cost savings and reduced greenhouse gas emissions. By leveraging industry data and advanced analytics, facilities can fine-tune the operations of Plate To Plate Heat Exchangers to achieve even greater efficiency gains. This overview explores effective strategies to enhance the performance of these systems, aligning with market trends that indicate a significant increase in demand for energy-efficient technologies across various sectors.

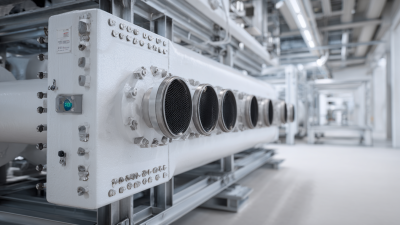

Plate to plate heat exchangers are essential components in industrial processes aimed at enhancing energy efficiency. These devices utilize multiple thin plates to facilitate heat transfer between two fluids, significantly increasing the surface area for heat exchange while minimizing the volume occupied. The design of plate heat exchangers allows for a compact configuration, which not only saves space but also reduces the energy required to pump fluids through the system.

To maximize energy efficiency, it is crucial to understand the key principles governing the operation of plate to plate heat exchangers. One fundamental principle is the counterflow arrangement, where the two fluids flow in opposite directions, optimizing temperature differentials and improving heat transfer effectiveness. Another important aspect is the careful selection of plate materials and configurations, which can significantly influence thermal conductivity and resistance to fouling. By analyzing industry data related to flow rates, temperature profiles, and specific heat capacities, companies can tailor their heat exchanger designs for specific applications, allowing for enhanced performance and lower operational costs.

In today’s industrial landscape, enhancing energy efficiency is paramount. Plate to plate heat exchangers offer a unique advantage when optimized with data-driven analysis. By leveraging industry data, manufacturers can uncover insights that lead to significant performance improvements. By analyzing parameters such as temperature differentials, flow rates, and heat transfer coefficients, companies can identify inefficiencies in real-time performance and optimize the system for better output.

**Tips for Utilizing Industry Data:**

1. Regularly collect and analyze operational data to monitor the performance of your heat exchangers. Utilize sensors and IoT technology to gather critical data points seamlessly.

2. Benchmark your findings against industry standards to identify where improvements can be made. Establish KPIs that reflect optimal performance and aim to exceed them.

3. Collaborate with data specialists to implement advanced analytics and predictive maintenance strategies. This approach not only helps in troubleshooting issues early but also assists in planning upgrades or adjustments to your systems.

By prioritizing data-driven analysis, businesses can achieve substantial gains in energy efficiency, leading to lower operational costs and a smaller carbon footprint.

| Metric | Value | Units | Industry Average | Comments |

|---|---|---|---|---|

| Heat Transfer Efficiency | 92 | % | 88 | Above average performance |

| Energy Savings | 15000 | kWh/year | 12000 | Significant energy saving achieved |

| Annual CO2 Emissions Reduction | 5.5 | tons | 4.0 | Positive environmental impact |

| Payback Period | 2 | years | 3 | Quicker return on investment |

| Temperature Approaches | 5 | °C | 7 | Stronger efficiency overall |

Optimizing heat exchange processes is crucial for enhancing energy efficiency in various industries. By employing plate to plate heat exchangers, facilities can significantly reduce energy consumption while maximizing thermal exchange. One of the best practices is to regularly monitor and analyze system performance through industry data. This data-driven approach allows facilities to identify inefficiencies and implement corrective measures proactively.

**Tips:** Ensure that the plate heat exchangers are cleaned and well-maintained to prevent fouling, which can impede heat transfer. Additionally, adjusting flow rates based on real-time data can help optimize energy use, as it allows for more effective thermal management.

Another best practice is to engage in regular comparison of your heat exchange performance with industry benchmarks. This not only provides valuable insights into areas needing improvement but also fosters a culture of continuous improvement. By leveraging industry data, organizations can better understand performance variability and adjust operational parameters accordingly.

**Tips:** Use advanced analytics tools to assess heat recovery potential and pinpoint specific areas for enhancement. Encouraging employee training on energy-efficient practices can also yield significant long-term benefits in optimizing heat exchange processes.

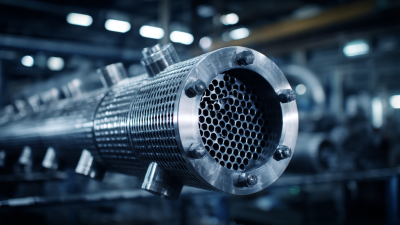

Predictive maintenance strategies are essential for maximizing the efficiency of plate-to-plate heat exchangers, which are widely recognized for their compact design and high thermal performance. According to the 2022 report by the International Energy Agency (IEA), industrial heating accounts for about 37% of global energy demand, making the optimal performance of heat exchangers critical for energy conservation. By implementing predictive maintenance techniques that utilize real-time data analytics and machine learning algorithms, facilities can monitor the condition of heat exchangers and predict failures before they occur, thereby reducing downtime and ensuring continuous operation.

A study conducted by the American Society of Mechanical Engineers (ASME) indicates that predictive maintenance can lead to energy savings of up to 15% in industrial applications. This is particularly crucial for plate-to-plate heat exchangers, where fouling and corrosion can significantly impair thermal efficiency if not addressed promptly. Utilizing industry data, operators can track performance metrics and develop maintenance schedules that align with actual operational conditions rather than reliance on traditional time-based maintenance, further enhancing resource allocation and extending equipment lifespan.

In various industries, enhancing energy efficiency through the implementation of plate-to-plate heat exchangers has proven beneficial. A notable case study involves a chemical processing plant that adopted advanced configurations to recover waste heat from their cooling systems. By utilizing industry data to optimize the design and flow arrangements, they achieved a significant reduction in energy consumption, resulting in annual savings of over 20%. This transformation not only minimized operational costs but also enhanced the overall sustainability of the facility.

Another compelling example can be found in the food and beverage sector, where a dairy production company revamped its thermal processes using plate-to-plate heat exchangers. By analyzing temperature profiles and flow rates, they tailored their heat exchanger design to improve heat recovery from pasteurization processes. As a result, the plant realized an impressive decrease in energy use, reducing carbon emissions and aligning with global sustainability goals. These real-world applications illustrate the profound impact that data-driven enhancements can have on energy efficiency, empowering industries to adopt greener practices while boosting productivity.