Leave Your Message

Choosing the right industrial heat exchanger is a critical decision for any business involved in processes requiring heat transfer. Industrial heat exchangers come in various types, designs, and materials, each tailored to meet specific operational needs and efficiency requirements. Understanding the fundamental principles of heat exchange, along with your facility's unique operational parameters, is essential in determining the optimal solution.

Choosing the right industrial heat exchanger is a critical decision for any business involved in processes requiring heat transfer. Industrial heat exchangers come in various types, designs, and materials, each tailored to meet specific operational needs and efficiency requirements. Understanding the fundamental principles of heat exchange, along with your facility's unique operational parameters, is essential in determining the optimal solution.

Factors such as temperature range, pressure levels, and the nature of the fluids being processed play significant roles in this selection process. Additionally, considerations around maintenance, space constraints, and budget may also influence your decision.

This guide aims to illuminate the necessary steps and factors to consider, ensuring you make an informed choice that enhances both performance and cost-effectiveness in your industrial applications.

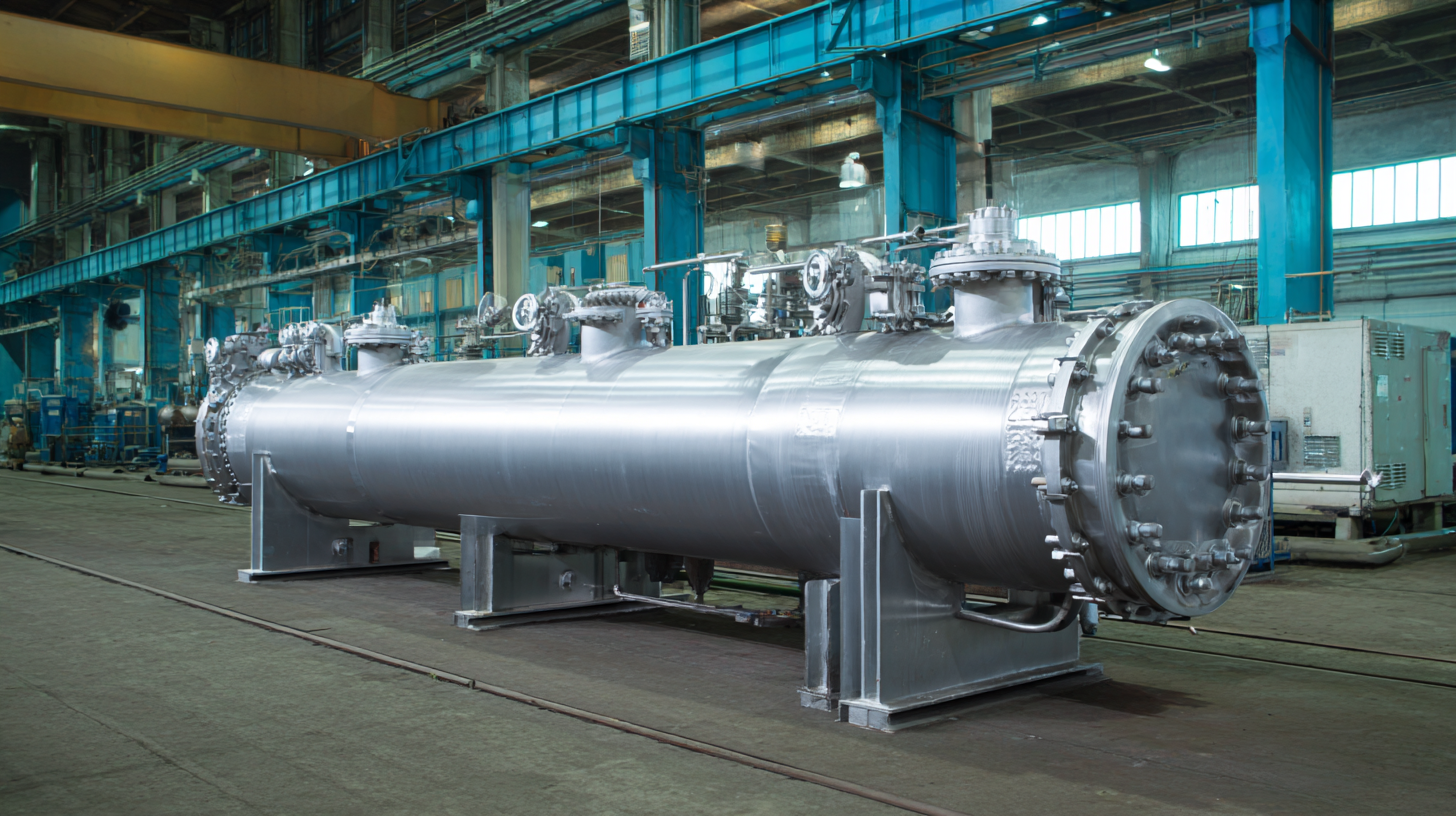

When selecting an industrial heat exchanger, it’s essential to understand the various types available and their specific applications. Common types include shell and tube, plate, and air-cooled heat exchangers, each designed to meet different operational needs. Shell and tube heat exchangers are ideal for high-pressure applications and are widely used in oil refineries and chemical processes due to their robustness. On the other hand, plate heat exchangers are more compact and efficient in transferring heat, making them suitable for food processing and HVAC systems.

Air-cooled heat exchangers serve a different function by utilizing ambient air to dissipate heat. They are commonly employed in power plants and petrochemical industries where water resources may be limited. Understanding these differences is crucial for choosing the right heat exchanger that aligns with your operational parameters, efficiency requirements, and cost constraints. Evaluating the specific needs of your application will guide you in selecting the most suitable heat exchanger type to optimize performance and reliability.

When selecting the right industrial heat exchanger, several key factors must be carefully evaluated to ensure optimal performance for your specific needs. First, consider the type of fluids involved. The compatibility of the heat exchanger material with the fluids significantly impacts efficiency and durability. For instance, corrosive fluids may necessitate materials like stainless steel or specialized alloys. Additionally, the temperature and pressure of the system should align with the heat exchanger's specifications to prevent operational failures.

Tips: Always consult with your supplier regarding fluid properties and environmental conditions. This preemptive step can prevent costly mistakes and enhance the longevity of your heat exchanger.

Another critical factor to evaluate is the heat transfer efficiency required for your application. Different heat exchanger designs, such as shell-and-tube or plate types, offer varying efficiencies and operational costs. Assessing the required heat transfer rates alongside the space available for installation will guide you toward the most suitable design.

Tips: Conduct a thorough analysis of your thermal requirements using simulation tools to identify the most efficient configuration before purchasing. This investment in time can lead to significant long-term savings in energy costs.

| Factor | Description | Considerations |

|---|---|---|

| Fluid Type | Identify the types of fluids that will be processed (e.g., liquid, gas). | Corrosivity, temperature, and pressure requirements. |

| Thermal Performance | The ability of the heat exchanger to efficiently transfer heat. | Target temperature changes and flow rates. |

| Size and Space | Physical dimensions and footprint of the heat exchanger. | Available installation space and accessibility for maintenance. |

| Material Selection | Materials used for construction based on the fluids and temperatures. | Corrosion resistance and thermal conductivity. |

| Maintenance Requirements | Frequency and ease of maintenance for the heat exchanger. | Access to components and cleaning methods. |

| Cost | Initial purchase price and total cost of ownership. | Budget constraints and long-term operational costs. |

When selecting the right industrial heat exchanger, it's crucial to evaluate performance metrics that indicate efficiency. Recent studies have shown that innovative designs, such as helical coil heat exchangers with twisted tube geometries, can enhance thermal-hydraulic performance significantly. The comparative analysis between conventional circular tubes and these advanced configurations highlights the importance of geometry in optimizing heat transfer and fluid flow.

**Tips:** Focus on the specific thermal requirements of your application when choosing a heat exchanger design. Look for options that offer enhanced features, like dimpled surfaces, which improve heat transfer through increased turbulence. Additionally, consider using computational fluid dynamics (CFD) simulations to predict performance under various conditions.

Moreover, the evolution of heat exchanger technologies, such as segmental baffle designs in shell and tube systems, can greatly influence overall efficiency. The inclination angles and spacing used in these designs play a vital role in the effective management of fluid dynamics. Evaluating these metrics not only aids in selecting the right heat exchanger but also ensures optimal operational performance and reduced energy costs.

This chart illustrates the various performance metrics relevant to industrial heat exchangers. Each metric is assessed based on its effectiveness, with heat transfer efficiency being the most critical factor, followed by pressure drop, cost, maintenance frequency, size, and material durability.

When selecting an industrial heat exchanger, assessing material compatibility and durability is paramount to ensure longevity and optimal performance. According to a recent report by the Heat Transfer Research Institute, over 30% of heat exchanger failures can be traced back to inappropriate material selection. This highlights the need for rigorous evaluation of the materials used in construction, particularly in environments subject to corrosive chemicals or extreme temperatures.

For example, stainless steel is widely favored for its resistance to rust and corrosion, making it suitable for food processing and chemical industries. However, in applications involving high acidity or alkalinity, specialized alloys such as Hastelloy or titanium might be required to enhance durability and prevent premature degradation. A comprehensive material compatibility assessment not only minimizes maintenance costs but also extends the operational lifespan of the heat exchanger, which can considerably reduce total lifecycle costs by up to 20%, as indicated in the 2022 Industrial Equipment Sustainability Report. By prioritizing material compatibility, businesses can optimize their heat exchanger selection process, ensuring that it meets specific operational demands while sustaining efficiency and reliability over time.

When selecting an industrial heat exchanger, the financial considerations of cost versus performance are crucial. While the initial purchase price of a heat exchanger might seem like the primary factor, it’s essential to account for its operational efficiency and long-term durability. An inexpensive unit may save you money upfront, but if it requires frequent repairs or consumes more energy, the overall costs could quickly escalate.

**Tips:** Before making a decision, conduct a life cycle cost analysis. This method evaluates all associated costs, including installation, operation, maintenance, and eventual replacement. Additionally, consider the payback period for your investment; a higher-performing heat exchanger may have a steeper initial cost but could lead to significant savings in energy bills and maintenance over time.

Moreover, assess the specific performance requirements of your application. Different processes might necessitate unique heat transfer capabilities or fluid compatibility. Matching the heat exchanger type and materials to your operational needs can prevent costly inefficiencies and failures in the future. Investing time in a thorough evaluation now can lead to better financial outcomes and operational performance in the long run.