Leave Your Message

In the ever-evolving landscape of industrial processes, the selection of a Phe Heat Exchanger is crucial for optimizing efficiency and ensuring operational effectiveness. According to Dr. Emily Stanton, a renowned expert in thermal management systems, "Choosing the right Phe Heat Exchanger isn't just about performance; it's about understanding the unique requirements of your specific application." This insight underscores the importance of tailoring your choice of heat exchanger to the distinctive needs of your industry.

Selecting the appropriate Phe Heat Exchanger involves a careful assessment of various factors, including thermal performance, fluid properties, and space considerations. The decision-making process can significantly impact energy consumption and overall productivity. As industries strive for sustainability and cost-effectiveness, understanding the nuances of these heat exchangers becomes increasingly vital. Emphasizing the significance of tailored solutions, Dr. Stanton notes that "a well-matched Phe Heat Exchanger can lead to marked improvements in both energy usage and maintenance costs." This highlights the essential balance between technical specifications and practical application, paving the way for informed decision-making in today's industrial environment.

Plate heat exchangers (PHEs) are critical in various industrial applications, ranging from food processing to chemical manufacturing. Understanding the basic operating principles and functionalities of PHEs can help engineers and decision-makers choose the right system for their industrial needs. PHEs consist of multiple plates that create channels for fluids to pass through, allowing for a highly efficient heat transfer process. According to the U.S. Department of Energy, PHEs can improve energy efficiency by 10-30% when properly selected and applied, thereby significantly reducing operational costs.

The applications of PHEs are diverse, encompassing industries such as HVAC, pharmaceuticals, and power generation. These heat exchangers are preferred due to their compact design, superior thermal efficiency, and ease of maintenance. A report by MarketsandMarkets states that the global PHE market is projected to reach $10 billion by 2025, driven by increased demand for energy-efficient systems. In addition, the growing emphasis on sustainability and reduced energy consumption has led to heightened interest in innovative PHE designs that enhance heat recovery, making them an integral part of contemporary industrial systems.

When selecting a PHE (Plate Heat Exchanger) for industrial applications, there are several key factors to consider to ensure optimal performance and cost efficiency. First and foremost is the thermal efficiency required for your specific process. This involves assessing the temperature range and heat transfer requirements, which will dictate the size and design of the PHE. A thorough understanding of your operational parameters is essential in identifying a heat exchanger that can handle the requisite thermal load without compromising efficiency.

Another critical factor is the compatibility of the materials used in the construction of the PHE with the fluids involved. Different applications may expose the exchanger to corrosive fluids, which necessitates the use of materials specifically designed to withstand such conditions. Additionally, consider the pressure drop across the heat exchanger, as excessive pressure loss can lead to increased operational costs.

Ease of maintenance and cleaning should also be factored in, as this will impact the longevity and reliability of the heat exchanger in your industrial setting. Evaluating these elements will guide you in making an informed decision that meets your industrial needs effectively.

When selecting the right plate heat exchanger (PHE) for industrial applications, evaluating efficiency and performance metrics is crucial. According to the "2021 Heat Exchanger Market Report," PHEs demonstrate a thermal efficiency of up to 90%, significantly higher than conventional heat exchangers. This is largely due to the large surface area provided by the plates, which enhances heat transfer while occupying less physical space. Productivity gains can be realized through the adoption of PHEs as they enable tighter temperature control, reducing energy costs by approximately 20–30% in operations relying on thermal energy exchange.

Performance metrics such as the overall heat transfer coefficient (U-value) are essential in determining the suitability of a PHE for specific applications. Industry studies indicate that U-values can range from 500 to 700 W/m²K for PHEs, compared to 200–500 W/m²K for shell and tube heat exchangers. This substantial difference underscores the importance of selecting a PHE that aligns with the operational pressure and temperature conditions of the system. Furthermore, a lower pressure drop in PHEs can lead to enhanced fluid flow dynamics, which is vital for industries such as food processing and pharmaceuticals where maintaining product quality and integrity is paramount. Evaluating these metrics not only impacts efficiency but can also lead to a notable reduction in operational costs and energy consumption over time.

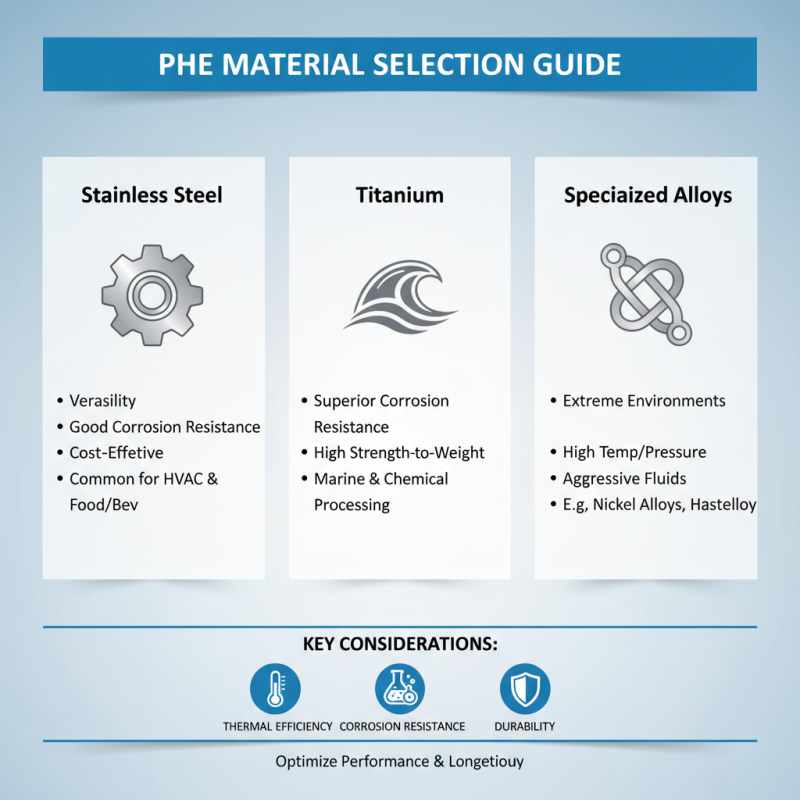

When it comes to selecting the right materials for your Plate Heat Exchanger (PHE), several factors must be considered to ensure optimal performance and longevity. The choice of materials greatly influences the thermal efficiency, corrosion resistance, and overall durability of the heat exchanger. Common materials for PHE components include stainless steel, titanium, and specialized alloys, each offering unique advantages based on the application and environmental conditions.

**Tips:** Always assess the fluid properties that will flow through the PHE. For aggressive chemicals or high temperatures, materials like titanium might be necessary to withstand corrosive effects. On the other hand, stainless steel is ideal for food and beverage industries due to its hygienic qualities and robustness.

Additionally, consider the pressure and temperature requirements of your industrial process. Selecting materials that can handle the specific pressure ranges will prevent failures and system inefficiencies. It's also wise to account for maintenance and cleaning processes, as easier-to-clean materials can reduce operational downtime.

**Tips:** When in doubt, consult with material experts who can provide insights into suitable alloys and treatments that enhance heat exchanger performance. Always prioritize the compatibility of materials with the fluids they will be exposed to in order to maximize effectiveness and lifespan.

Maintaining PHEs (Plate Heat Exchangers) is crucial for ensuring their longevity and optimal performance in industrial applications.

One of the best practices is to implement a regular inspection and cleaning schedule.

Over time, deposits can accumulate on the plates, which can hinder heat transfer efficiency and lead to increased energy costs.

Periodic cleaning, whether through chemical methods or mechanical processes, can help mitigate these issues and restore the heat exchanger's operational efficiency.

Another key aspect of maintenance involves monitoring the operating parameters closely.

Keeping track of temperature,

pressure, and flow rates allows operators to identify any anomalies early on.

Maintaining correct operating conditions not only enhances the efficiency of the heat exchanger but also prevents undue stress on the system, reducing the risk of premature wear or failure.

Additionally, training personnel on proper handling and operational procedures can foster a culture of maintenance that prioritizes the equipment's performance and longevity.