Leave Your Message

Choosing the right heat exchanger parts is a critical decision for optimizing energy efficiency and system performance in various industrial applications. According to a report by the International Energy Agency, heat exchangers account for approximately 25% of industrial energy consumption. With the growing emphasis on sustainability and cost reduction, selecting high-quality components tailored to specific operational requirements can significantly influence overall system reliability and efficiency. Moreover, research indicates that proper maintenance and part selection can lead to up to a 15% increase in energy efficiency in heat exchange processes. As industries face tighter regulations and rising energy costs, understanding the nuances of heat exchanger parts becomes essential for engineers and decision-makers aiming to enhance performance while minimizing environmental impact.

When selecting the right heat exchanger parts for your system, it is crucial to first identify the specific needs and specifications of your application. Recent advancements in heat exchanger technologies, such as finned tube heat exchangers, have shown to significantly enhance the thermal performance of phase change materials (PCMs). This is particularly beneficial in scenarios where efficient charging and discharging cycles are vital, such as in building energy management systems. According to experimental studies, these systems can optimally integrate PCMs, leading to improved energy efficiency in residential buildings.

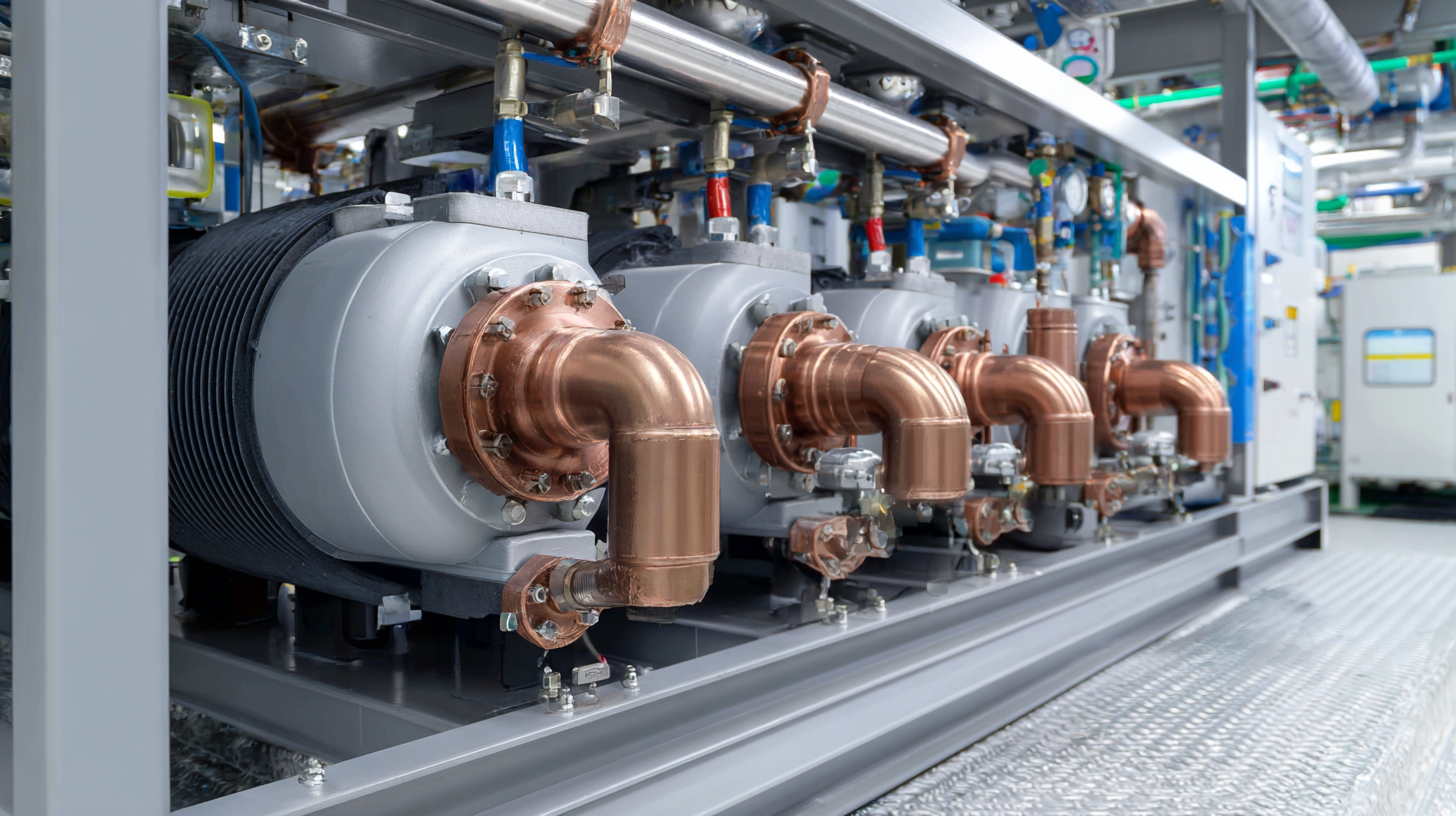

Additionally, a comprehensive review of recent research highlights the importance of dynamic system models that incorporate components like heat pumps and thermal energy storage. For instance, an extensive field study analyzed sensor data from over 1,000 heat pumps, revealing insights into their operational efficiency. Such data underscores the significance of matching the heat exchanger's design to the operational parameters of the system to achieve maximum efficiency.

By understanding the specific thermal demands and energy recovery capabilities of your system, you can make informed decisions about which heat exchanger components to incorporate, ensuring optimal performance and sustainability in your heating and cooling solutions.

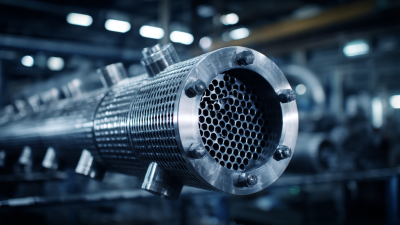

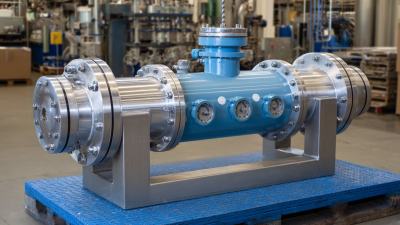

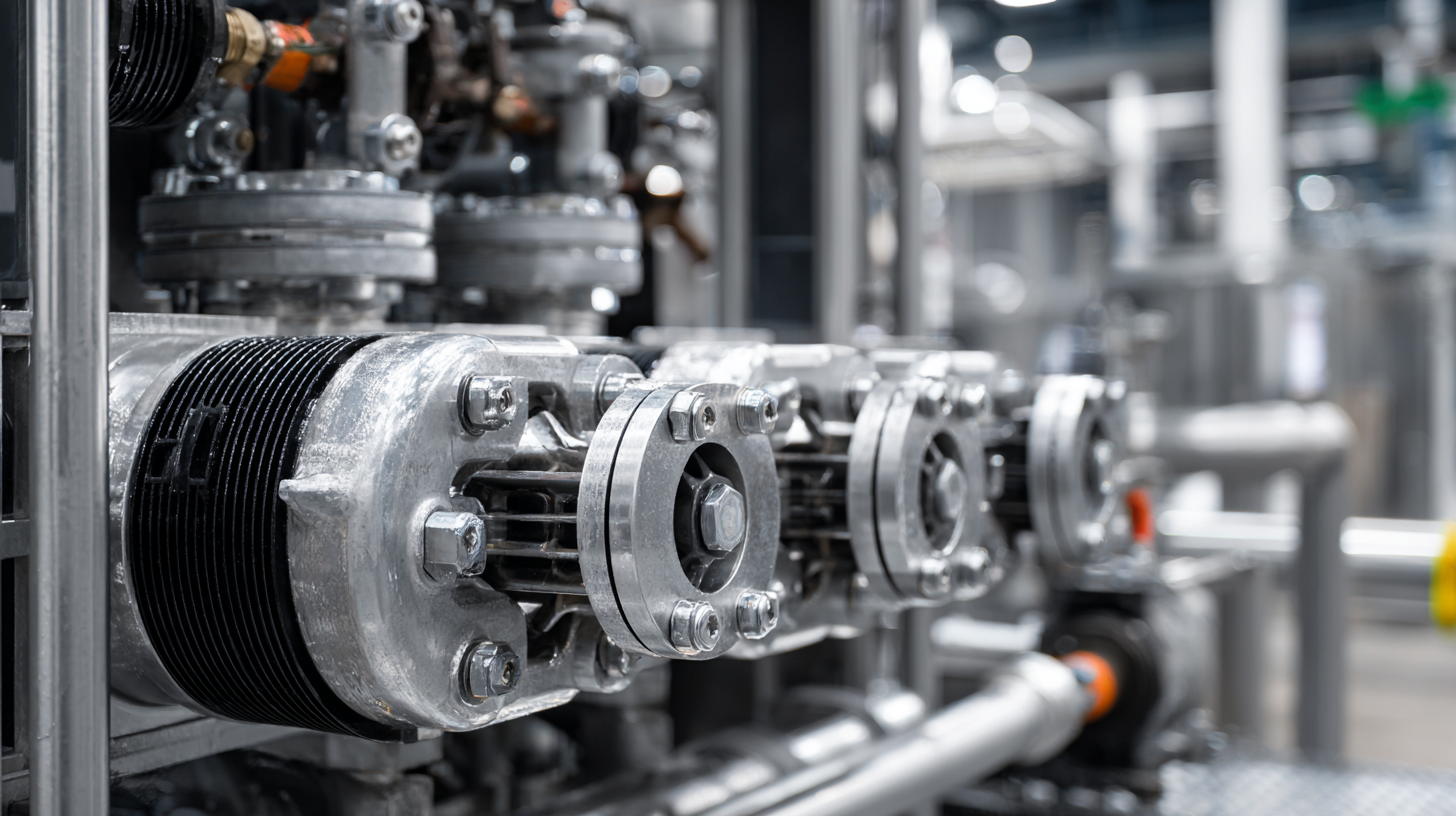

When selecting the right heat exchanger parts for your system, it's crucial to understand the different types of components available in the market. Heat exchangers contain various parts, including tubes, plates, gaskets, and frames, each serving a specific function. For instance, tubular heat exchangers use long, cylindrical tubes to separate hot and cold fluids, making them ideal for high-pressure applications. Plate heat exchangers, on the other hand, consist of thin plates stacked together, allowing for efficient heat transfer with a smaller footprint.

Additionally, materials play a significant role in performance and durability. Common materials include stainless steel, copper, and titanium, each offering different corrosion resistance and thermal conductivity. Gaskets are another vital consideration; they ensure a tight seal between components while resisting high temperatures and pressures. By understanding these diverse types and their individual characteristics, you can make informed decisions that enhance the efficiency and longevity of your heat exchanger system.

| Component Type | Material | Application | Heat Transfer Efficiency | Cost (Approx.) |

|---|---|---|---|---|

| Plate Heat Exchanger | Stainless Steel | HVAC, Food Processing | High | $1,200 - $3,000 |

| Shell and Tube Heat Exchanger | Copper | Oil Refining, Chemical Processing | Moderate | $2,000 - $5,000 |

| Air Cooled Heat Exchanger | Aluminum | Power Plants, Refrigeration | Low | $500 - $3,000 |

| Double Pipe Heat Exchanger | Carbon Steel | Heating and Cooling Systems | Moderate | $1,000 - $2,500 |

| Spiral Heat Exchanger | Titanium | Corrosive Applications, Wastewater Treatment | High | $3,000 - $8,000 |

When selecting heat exchanger parts for your system, evaluating material compatibility is crucial to ensure optimal performance and longevity. The material used in heat exchangers must withstand various thermal and chemical stresses while maintaining efficient heat transfer. For instance, recent research into polymeric shell and tube heat exchangers underscores how material selection can significantly impact heat transfer efficiency while addressing common problems such as fouling. Understanding the thermal conductivity, corrosion resistance, and mechanical properties of materials can lead to improved design choices.

When selecting heat exchanger parts for your system, evaluating material compatibility is crucial to ensure optimal performance and longevity. The material used in heat exchangers must withstand various thermal and chemical stresses while maintaining efficient heat transfer. For instance, recent research into polymeric shell and tube heat exchangers underscores how material selection can significantly impact heat transfer efficiency while addressing common problems such as fouling. Understanding the thermal conductivity, corrosion resistance, and mechanical properties of materials can lead to improved design choices.

Incorporating insights from studies, such as those exploring vacuum glazing for low-carbon buildings, can enhance the sustainability of heat exchanger systems. The examination of thermal efficiency in building applications emphasizes that material compatibility extends beyond mere function—the right materials can contribute to broader energy efficiency goals. This alignment between material selection and sustainability objectives highlights the importance of integrating innovative approaches, like hybrid systems, that optimize the performance of heat exchangers while also supporting renewable energy initiatives and reducing carbon emissions.

When assessing performance metrics for optimal heat exchanger parts, it is essential to consider several key factors that influence efficiency and durability. Thermal performance, for instance, can be evaluated through the overall heat transfer coefficient and the pressure drop across the heat exchanger. A higher overall heat transfer coefficient indicates that the material and design of the exchanger are effectively facilitating heat exchange. Similarly, minimizing pressure drop ensures that the system operates efficiently, reducing energy consumption and enhancing overall performance.

Additionally, the choice of materials significantly impacts the longevity and effectiveness of heat exchangers. Metrics such as corrosion resistance, thermal conductivity, and compatibility with the working fluids should guide the selection process. Materials should be assessed not just for their immediate performance in heat transfer, but also for how they will hold up under varying operational conditions over time. By carefully evaluating these performance metrics, system designers can select heat exchanger parts that not only improve efficiency but also ensure a reliable and long-lasting operation.

When selecting heat exchanger parts, considering maintenance and replacement factors is crucial for ensuring long-term efficiency and reliability. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of industrial heat exchangers experience failures primarily due to inadequate maintenance practices. This statistic highlights the importance of selecting components that are not only compatible with your system but also easy to maintain. For instance, opting for removable bundle designs can facilitate quicker inspections and repairs, thereby reducing downtime.

Furthermore, the longevity of heat exchangers heavily relies on the materials used in their construction. A study by the Heat Exchanger Institute (HEI) states that corrosion is responsible for 25% of the failures in these systems. By choosing corrosion-resistant materials such as titanium or specialized alloys, you can significantly enhance the lifespan of your heat exchangers. Regular assessments and proactive replacements of wear-prone parts can also contribute to smoother operation, as the costs associated with unplanned shutdowns can escalate swiftly. Prioritizing these aspects during the selection process will undoubtedly lead to better performance and reduced total lifecycle costs for your heat exchanger system.