Leave Your Message

In today’s industrial landscape, the efficient transfer of heat plays a pivotal role in enhancing processes across a multitude of sectors, from HVAC systems to food processing. The Brazed Plate Heat Exchanger (BPHE) stands out as a formidable solution due to its compact design and high thermal efficiency. According to the International Journal of Refrigeration, BPHEs can achieve up to 50% greater efficiency compared to traditional tubular heat exchangers, making them an attractive choice for applications requiring maximum performance with minimal footprint.

However, selecting the right Brazed Plate Heat Exchanger requires a thorough understanding of both the system requirements and the operating conditions. With the heat exchanger market projected to reach USD 39.9 billion by 2027, driven by advancements in energy systems and increasing demand for heat recovery solutions, the need for tailored designs becomes increasingly crucial. Factors such as maximum pressure, temperature range, and fluid type are pivotal in determining the optimal selection of a BPHE, ensuring not only efficiency but also reliability and longevity in operations.

By carefully evaluating these key parameters and understanding the specific application needs, businesses can leverage the advantages of Brazed Plate Heat Exchangers to improve their thermal management systems, reduce energy consumption, and comply with environmental regulations, ultimately contributing to a more sustainable future.

Brazed plate heat exchangers (BPHEs) are compact, efficient thermal devices widely used in various industries. Their unique construction, which involves bonding thin metal plates together, allows for superior heat transfer and reduced thermal resistance. According to a recent report by the International Energy Agency, BPHEs can achieve efficiency levels upwards of 90%, making them ideal for applications requiring heat recovery, refrigeration, and process cooling. Industries such as HVAC, food and beverage, and pharmaceuticals increasingly rely on these exchangers for their ability to provide high performance in limited space.

The versatility of brazed plate heat exchangers extends to their use in numerous applications. They are particularly beneficial in systems where space is at a premium, such as district heating, industrial processes, and even renewable energy systems like solar thermal. A study published by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlighted that BPHEs can effectively handle fluids with varying viscosities and temperatures, enhancing their applicability in diverse environments. Their robust design and ability to withstand high pressures also contribute to lower maintenance and operational costs over time, further solidifying their role in modern thermal management solutions.

| Feature | Standard Dimension | Material | Application | Efficiency |

|---|---|---|---|---|

| Heat Transfer Area | 1.5 - 50 m² | Stainless Steel | HVAC Systems | Up to 95% |

| Operating Pressure | 25 - 50 bar | Copper | Industrial Heating | High Efficiency |

| Connection Size | 1/2" - 4" | Titanium | Marine Applications | Very High |

| Temperature Range | -196°C to 200°C | Aluminium | Chemical Processing | Optimized |

When selecting a brazed plate heat exchanger, several key factors must be considered to ensure optimal performance and efficiency. First, it is essential to understand the specific heat transfer requirements of your application. Calculating the necessary heat transfer area based on the desired temperature exchange and the fluids involved will help identify the right size and capacity for the heat exchanger. Additionally, evaluating the thermal properties of the fluids is crucial, as factors such as viscosity, specific heat, and thermal conductivity can significantly impact the exchanger's overall performance.

Another important aspect to consider is the working pressure and temperature of the system. Brazed plate heat exchangers are designed to withstand certain ranges of pressure and temperature, and exceeding these limits can compromise efficiency or lead to failure. Furthermore, it’s vital to assess the potential for fouling and scaling based on the fluids used. Choosing materials that resist corrosion and fouling can prolong the lifespan of the unit and maintain its heat transfer efficiency. Lastly, installation space and integration with existing systems should also be taken into account, ensuring that the selected heat exchanger fits well within the design constraints and is compatible with other components in the system.

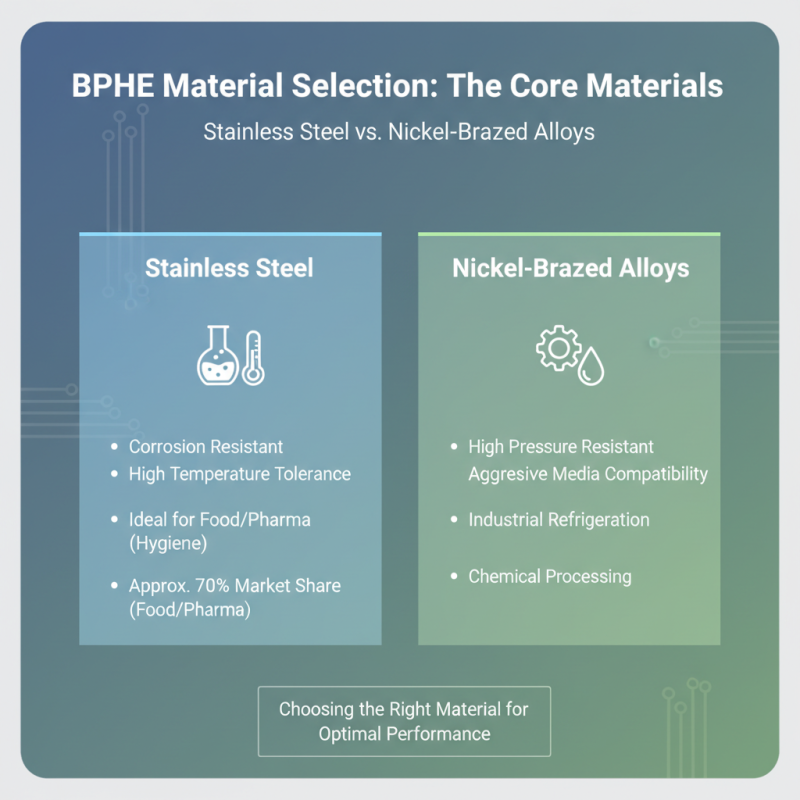

When selecting a brazed plate heat exchanger (BPHE), understanding the material types available is crucial for ensuring optimal performance. The most common materials used in BPHEs are stainless steel and nickel-brazed alloys. Stainless steel offers excellent resistance to corrosion and high temperatures, making it ideal for applications in industries such as food processing and pharmaceuticals. Reports indicate that around 70% of BPHEs in these industries utilize stainless steel due to its durability and hygiene properties.

On the other hand, nickel-brazed heat exchangers are favored in situations where aggressive media is involved. Nickel provides enhanced resistance against corrosive fluids, and studies show that it can extend the lifespan of the exchanger by up to 30% in harsh environments. This material type is gaining traction in chemical processing due to its robust performance under extreme conditions.

**Tips:** Consider the specific fluid types and temperatures in your application when choosing a material. For applications involving refrigerants, nickel-brazed exchangers are often more advantageous. Additionally, conducting a thorough analysis of the operating conditions can help you make an informed decision that aligns with your performance requirements and budget constraints. It's also essential to consult technical data sheets for the heat exchanger materials to understand their limits and best applications fully.

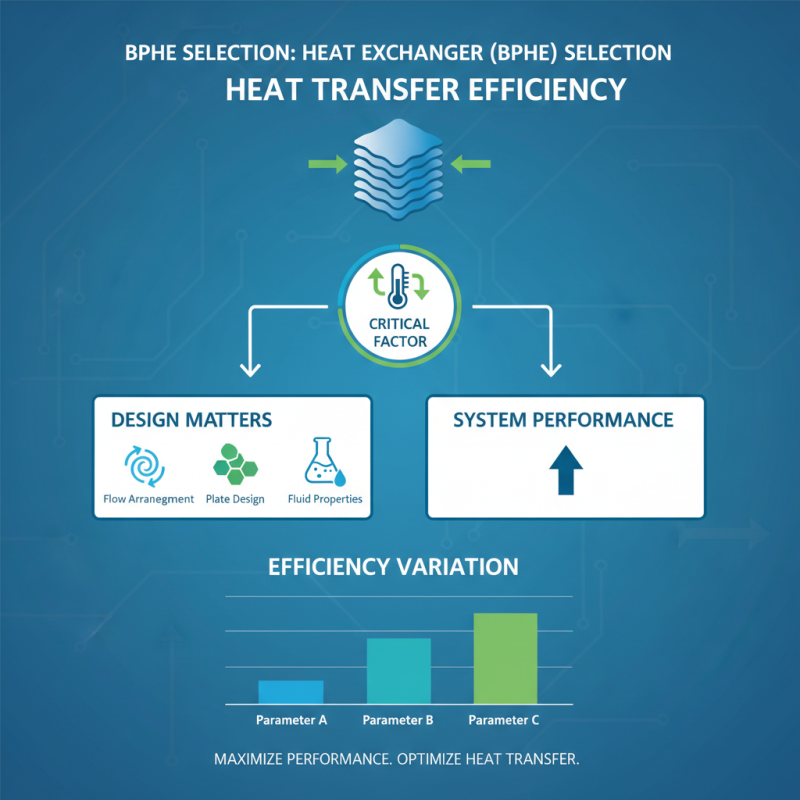

When selecting a brazed plate heat exchanger (BPHE), one of the most critical factors to consider is heat transfer efficiency. This metric is crucial, as it directly influences the overall performance of the system in which the heat exchanger operates. The design of BPHEs, featuring a series of thin plates with a large surface area, allows for effective heat transfer between two fluids. The efficiency can vary significantly based on several parameters, including the flow arrangement, plate design, and the properties of the fluids involved.

To evaluate heat transfer efficiency, it's essential to understand the concept of the heat transfer coefficient, which reflects how well the heat exchanger can transfer thermal energy. Factors such as fluid velocity, temperature difference, and the physical characteristics of the fluids (like viscosity) play pivotal roles in this assessment. It's also advisable to consider the pressure drop across the plates, as excessive pressure loss can lead to reduced flow rates and impact overall efficiency. By carefully analyzing these elements, one can fine-tune their choice of a brazed plate heat exchanger to ensure optimal performance aligned with specific operational needs.

When selecting a brazed plate heat exchanger (BPHE), assessing the appropriate size and capacity is crucial for ensuring optimal performance. The effectiveness of a BPHE is largely determined by its ability to transfer heat efficiently based on the specific application. According to a report by the International Energy Agency, an appropriately sized heat exchanger can improve energy efficiency by up to 30%, making it imperative to consider not only the surface area but also the flow rates of both the heating and cooling fluids.

To achieve the desired performance, one must calculate the required heat transfer rate, which can be derived from the equation Q = ṁ * Cp * ΔT, where Q is the heat transfer rate, ṁ is the mass flow rate, Cp is the specific heat capacity, and ΔT is the temperature difference between the inlet and outlet. Industry data suggests that a typical BPHE operates efficiently with a temperature differential of around 5-10°C. Ensuring that the chosen unit can accommodate these parameters while considering factors like fluid properties and pressure drop will lead to a more effective thermal management solution.

Additionally, it is essential to gauge the specific thermal load demands of your application. A study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that selecting the wrong size can lead to inefficiencies, resulting in energy wastage that can be as high as 20% in residential applications. Thus, careful attention to the sizing and capacity of a brazed plate heat exchanger ensures not only peak performance but also longevity and reliability in heat transfer processes.