Leave Your Message

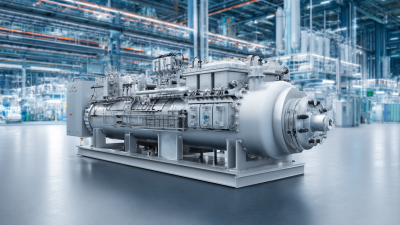

In the realm of industrial heat exchange, the Bpx Heat Exchanger stands out for its efficiency and innovation. According to Dr. Emily Renshaw, a leading expert in thermal engineering, “The Bpx Heat Exchanger transforms how industries manage heat.” This technology is not only critical for energy conservation but also essential for improving process reliability.

Industries today face numerous challenges, from rising energy costs to increasing operational demands. The Bpx Heat Exchanger provides a viable solution, optimizing thermal performance while minimizing environmental impact. With its unique design, this heat exchanger ensures enhanced heat transfer rates, reducing waste and maximizing output. However, implementing this technology requires careful consideration of various factors, including compatibility with existing systems.

While the advantages are significant, users must acknowledge potential drawbacks too. Installation and maintenance of the Bpx Heat Exchanger can be complex, requiring skilled personnel. Moreover, there may be initial costs that deter some companies from making the switch. Reflecting on these aspects is crucial in making informed decisions for better industrial processes.

Heat exchangers play a crucial role in industrial processes. They transfer heat between fluids efficiently. Bpx heat exchangers stand out due to their unique design. They maximize surface area, which leads to enhanced heat transfer. Industries benefit from this efficiency in various ways.

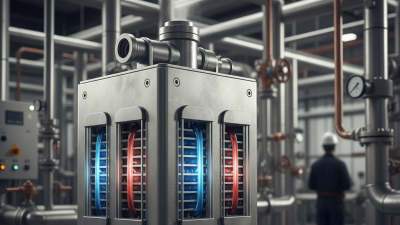

In manufacturing, temperature control is vital. A Bpx heat exchanger can maintain optimal conditions. This is important for processes like chemical reactions. If the temperature is not regulated, the outcome can be inconsistent. That can lead to wasted resources. It's essential to understand this balance in operations.

Maintenance can be a challenge too. While Bpx exchangers are designed for durability, regular checks are necessary. Over time, buildup might occur, affecting performance. Operators should remain vigilant. Identifying small issues early can prevent larger failures later. Adequate training for staff is critical. They must know how to monitor and maintain these systems effectively.

Bpx heat exchangers are gaining popularity in the industrial sector due to their distinctive advantages. These units offer improved thermal efficiency when compared to traditional models. According to recent industry reports, Bpx exchangers can enhance heat transfer efficiency by up to 30%. This leads to reduced energy consumption and lower operational costs.

Another appealing aspect of Bpx heat exchangers is their compact design. Space-saving solutions are increasingly crucial for industries facing space constraints. The smaller footprint of Bpx units enables easier installation, even in tight areas, reducing overall setup time. This can directly translate to faster project timelines.

**Tips:** Consider the specific heat load requirements of your application. This will ensure optimal performance from your Bpx heat exchanger. Regular maintenance is also essential. Neglecting upkeep can lead to diminished efficiency and higher costs. Additionally, while Bpx units are efficient, not all applications suit them perfectly. A careful evaluation is necessary to avoid potential performance issues in specific scenarios.

Bpx heat exchangers are versatile tools used in many industries. They provide efficient heat transfer solutions, which are crucial for various applications. In power generation, for example, they help optimize thermal efficiency. These systems ensure that energy waste is minimized. This process is fundamental, especially in sectors where energy costs significantly impact profitability.

In chemical processing, Bpx heat exchangers play a critical role. They facilitate controlled reactions by regulating temperatures. This precision enhances product quality and consistency. However, challenges can arise. Sometimes, maintenance is overlooked, leading to efficiency drops. Regular checks are important to ensure optimal performance.

Food processing also benefits from Bpx heat exchangers. They are essential for pasteurization and cooling processes. This prevents spoilage and maintains food safety. Yet, there are concerns about ensuring hygiene standards. Any lapse may lead to contamination. Balancing efficiency and safety is an ongoing challenge. These applications highlight the complexity of using Bpx heat exchangers across different sectors.

| Industrial Sector | Heat Exchanger Type | Application | Advantages |

|---|---|---|---|

| Chemical Processing | Shell and Tube | Cooling and Heating of Chemicals | High Efficiency, Durable |

| Oil and Gas | Plate Heat Exchanger | Crude Oil Heating | Compact Design, Low Maintenance |

| Power Generation | Double Pipe Heat Exchanger | Cooling of Turbine Oil | Robust Performance, High Capacity |

| Food and Beverage | Air Cooled Heat Exchanger | Pasteurization Processes | Energy Saving, Hygiene Compliance |

| Pharmaceuticals | Finned Tube Heat Exchanger | Process Cooling | Customized Designs, High Efficiency |

When considering maintenance for Bpx heat exchangers, the focus should be on efficiency and reliability. Regular maintenance can enhance the lifespan of these units significantly. Industry reports suggest that proper care can elevate operational efficiency by up to 30%. Over time, neglecting maintenance can lead to scaling and fouling, which directly impacts heat transfer efficiency.

Monitoring key performance indicators is crucial. For instance, tracking pressure drops across the heat exchanger can indicate potential issues early. A 2019 study highlighted that facilities that adopted predictive maintenance saw a 20% reduction in downtime. While maintenance might seem straightforward, many operations struggle with it. The need for skilled technicians can create gaps in effective upkeep.

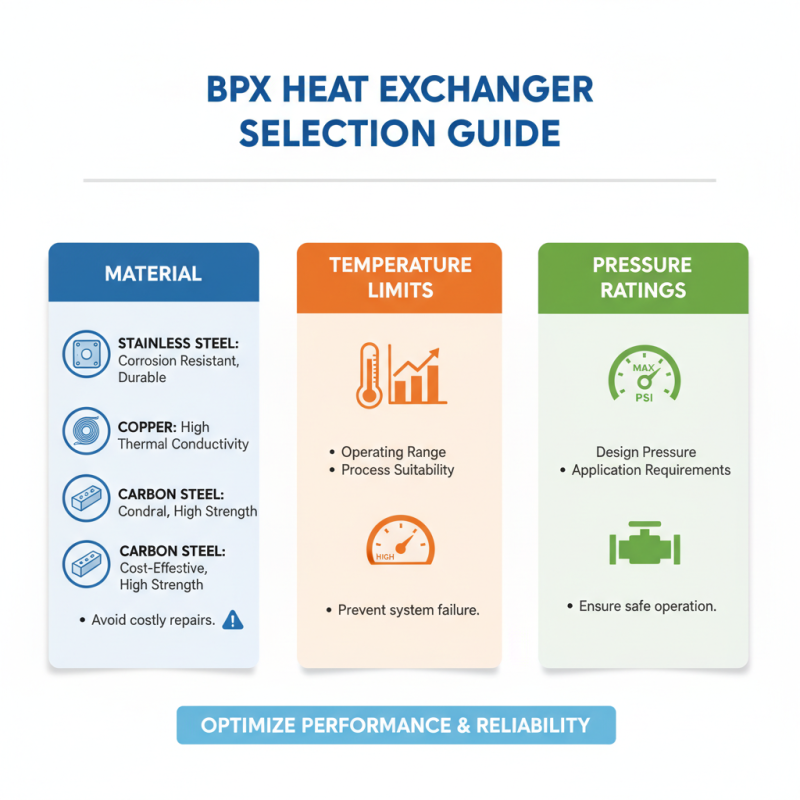

Another consideration is the materials used in these exchangers. Corrosion resistance needs assessment based on operating conditions. A material mismatch can lead to premature failures. The challenge lies in balancing cost with long-term performance. Many industries face this dilemma, often prioritizing short-term savings over longevity. Awareness of these factors can reinforce better maintenance strategies in the long run.

When selecting a Bpx heat exchanger, multiple factors come into play. The material is crucial. Stainless steel, copper, or carbon steel can significantly affect durability and efficiency. Choosing the wrong material can lead to costly repairs and downtime. Consider the temperature limits and pressure ratings required for your specific applications. A mismatch could cause failure.

Another critical factor is the design type. Whether you need a shell-and-tube or plate-and-frame design will depend on your space and performance needs. Adequate surface area affects heat transfer efficiency. It’s essential to understand your system’s flow rates, as this influences the exchanger's size. Sometimes, specifications get overlooked, leading to operational inefficiencies.

Maintenance should not be ignored. Easy access can save time and costs in the long run. However, choosing a model that accommodates easy cleaning or part replacement can be challenging. Not every design offers this feature. Reflect on these aspects thoroughly to avoid future headaches. Sometimes, the smallest details can lead to significant setbacks.