Leave Your Message

In the highly demanding field of thermal management, selecting the right Heat Exchanger Parts is crucial for optimizing system efficiency and performance. According to a recent report by the International Energy Agency (IEA), improperly selected or maintained heat exchangers can lead to energy losses of up to 30%, significantly impacting operational costs and environmental sustainability. As industries strive to meet stringent regulatory standards and reduce carbon footprints, understanding the nuances of heat exchanger components becomes imperative. With advancements in materials and technology, the market for heat exchanger parts is expected to grow at a CAGR of 6.5% through 2027, reflecting an increasing emphasis on efficiency and performance. This blog aims to provide essential tips to guide engineers and decision-makers in selecting the optimal parts for their heat exchange systems, ensuring not only peak operational efficiency but also longevity and reliability.

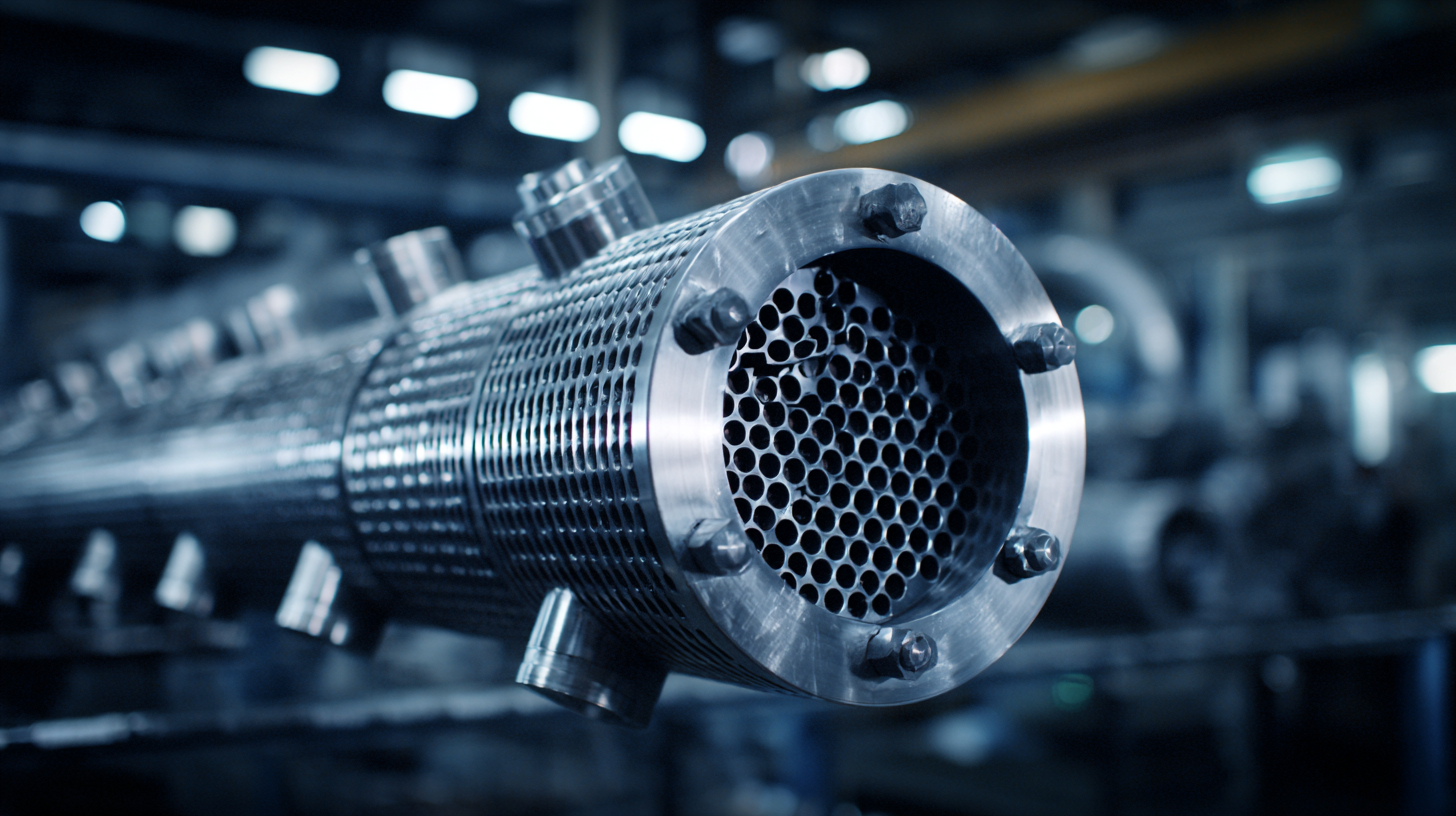

When selecting heat exchanger parts, understanding the key components involved is crucial for ensuring efficient operation. Heat exchangers are comprised of various critical elements, including tubes, fins, and headers. According to a report published by the International Journal of Refrigeration, up to 70% of the energy consumption in industrial processes can be attributed to inefficient heat exchangers. A detailed analysis of these parts reveals that selecting the right materials and configurations can significantly improve thermal efficiency. For instance, using enhanced surface designs, such as corrugated or finned tubes, can increase heat transfer rates by 20-30% compared to standard designs.

Additionally, materials play a pivotal role in the performance of heat exchangers. According to a study by the American Society of Mechanical Engineers (ASME), material selection based on thermal conductivity, corrosion resistance, and mechanical strength can influence the longevity and efficiency of heat exchangers. Stainless steel and titanium are often recommended for their superior corrosion resistance, particularly in harsh environments. Investing in high-quality components not only minimizes downtime but can also lead to lower operational costs, effectively impacting the bottom line of businesses relying on thermal systems.

When selecting heat exchanger parts for your system, several critical factors need to be considered to ensure optimal performance. First and foremost, the material of the heat exchanger components plays a significant role in efficiency and durability. Depending on the working environment and the fluids involved, materials like stainless steel, copper, or specialized alloys may be preferred. Their ability to resist corrosion, withstand high temperatures, and handle varying pressure levels directly impacts the longevity and effectiveness of the heat exchanger.

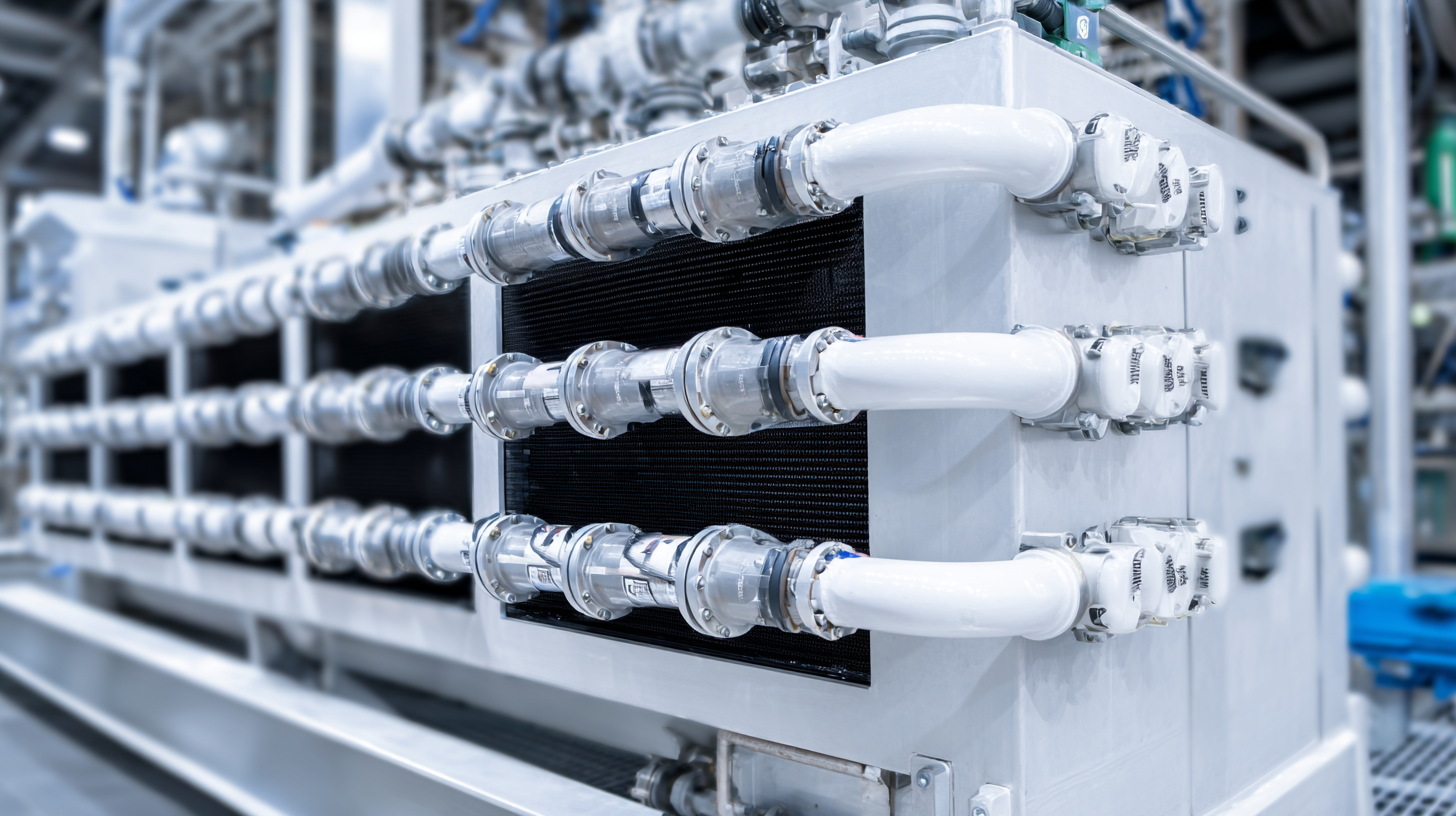

Another vital factor is the size and design of the parts. Proper sizing ensures adequate heat transfer and fluid flow without causing excessive pressure drops or energy losses. It's essential to consider the specific requirements of your application, including flow rates and temperature differentials, to select components that will work together harmoniously.

Additionally, factors such as the type of heat exchanger—be it shell-and-tube, plate, or finned-tube—can influence which parts are most suitable for your system. Taking the time to evaluate these elements will lead to a more efficient and reliable heat exchange process.

When selecting materials for heat exchanger parts, the balance between durability and thermal conductivity is paramount. Common materials include stainless steel, copper, and aluminum, each offering distinct benefits. Stainless steel, for example, is renowned for its corrosion resistance and mechanical strength, which makes it ideal for high-pressure environments. According to a report by the International Energy Agency, stainless steel has an average lifespan of 20 years in harsh conditions, making it a reliable choice for long-term performance.

On the other hand, copper is celebrated for its superior thermal conductivity, which can enhance the efficiency of heat exchangers. Studies show that copper can improve heat transfer rates by up to 30% compared to other materials. However, its susceptibility to corrosion in certain environments must not be overlooked. When choosing copper components, consider applying protective coatings to extend their lifespan.

Tips for Choosing Materials:

When it comes to maintaining the efficiency of heat exchanger parts, regular maintenance is crucial to prolonging their lifespan. One key tip is to schedule routine inspections to identify any signs of wear or corrosion early on. By examining the outer surfaces and the connections for leaks or damage, you can prevent minor issues from escalating into major problems. Additionally, keeping the heat exchangers clean is vital; fouling can significantly reduce heat transfer efficiency. Implementing a cleaning schedule that uses appropriate cleaning agents can aid in avoiding buildup.

Another important aspect of maintenance is monitoring the operating conditions. Ensuring that the heat exchanger operates within the specified temperature and pressure limits can minimize stress on the components. Over time, fluctuations in these parameters can lead to fatigue and failure. Moreover, regular checks of fluid quality are necessary since contaminants can cause erosion and wear. By staying proactive in these maintenance practices, you can enhance the reliability and efficiency of your heat exchanger parts, ultimately ensuring their optimal performance over time.

This chart illustrates the impact of various factors on the performance of heat exchanger parts. Maintaining high material quality and frequent maintenance significantly enhance efficiency, while installation methods and operating conditions also play crucial roles.

When selecting heat exchanger components, one prevalent mistake is overlooking compatibility with existing systems. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), roughly 15% of heat exchanger failures result from mismatched materials leading to corrosion or thermal inefficiency. It’s crucial to ensure that the materials used for new components can withstand the specific corrosive environments and thermal conditions they will encounter, thereby optimizing the overall performance and longevity of the system.

Another common pitfall is neglecting the importance of proper sizing. A study from the Heat Transfer Research Institute indicates that improperly sized heat exchangers can lead to a 20-30% increase in operational costs due to inefficiencies. Sizing should account not only for flow rates but also for the desired temperature change and heat transfer requirements. By carefully analyzing these factors and avoiding assumptions based on previous experiences, engineers can make informed choices that enhance both efficiency and functionality in their heat exchanger systems.