Leave Your Message

A Brazed Plate Heat Exchanger is a highly efficient device used in various industries. It excels in transferring heat between two fluids without mixing them. This equipment is compact, making it suitable for space-limited environments. Its design consists of multiple thin plates that are brazed together, forming a network for fluid flow.

These heat exchangers offer several benefits. They provide excellent thermal performance and save energy. Their smaller size means they are easier to install and maintain. However, some may question their durability compared to larger models. Over time, brazed connections might weaken, demanding careful monitoring.

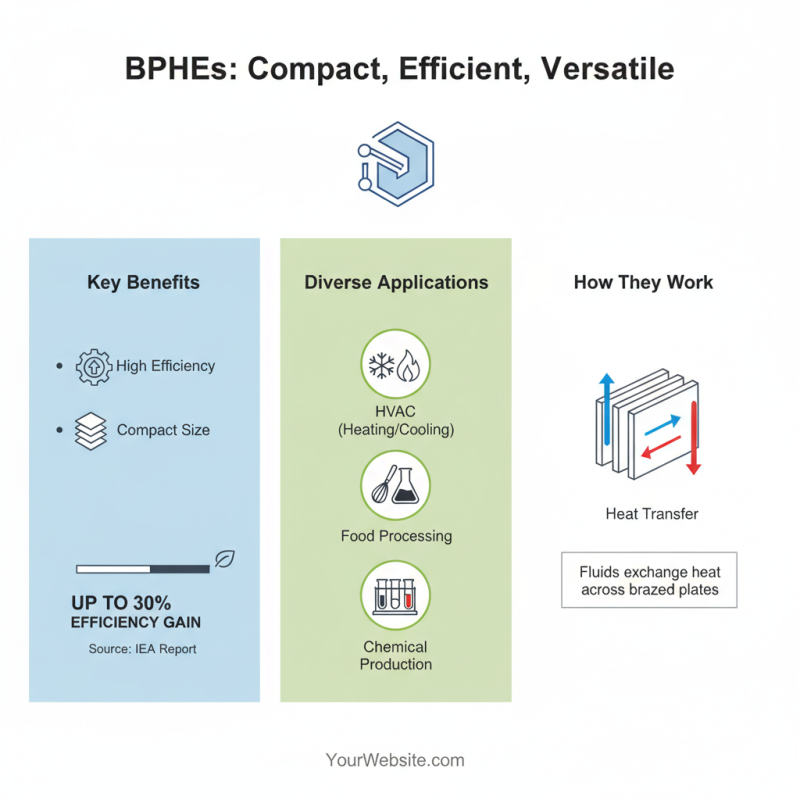

In industries like food processing and HVAC, Brazed Plate Heat Exchanger plays a crucial role. These systems enhance efficiency but must be used properly to avoid issues. While they are innovative, potential users should consider both advantages and limitations.

A brazed plate heat exchanger (BPHE) is a compact equipment designed for thermal transfer. It consists of thin plates that are brazed together, forming multiple channels for fluid flow. This design enhances efficiency by increasing the surface area for heat exchange. The high thermal performance often exceeds traditional shell-and-tube systems. According to industry reports, BPHE can offer efficiency improvements of up to 30%.

The functionality of a brazed plate heat exchanger lies in its unique construction. Hot and cold fluids flow through alternating channels, allowing for effective heat transfer. The small size makes it suitable for various applications, from refrigeration to oil cooling. Researchers have shown that BPHE can operate at high pressures and temperatures, offering versatility in demanding environments.

Tips: When installing a BPHE, ensure proper alignment to reduce potential leaks. Regular maintenance checks can enhance performance longevity. Also, be mindful of fluid compatibility; some aggressive fluids can damage the plates over time. It's essential to choose appropriate materials for the fluids involved to maintain efficiency. Embracing BPHE technology can streamline operations but requires a thorough understanding to avoid common pitfalls.

Brazed plate heat exchangers are efficient devices. Their design features make them distinct. The key components include thin metal plates. These plates are stacked together, forming channels. The liquid flows through these channels, enhancing heat transfer.

The brazing process bonds the plates. This creates a strong, leak-proof unit. However, the design also has challenges. The tight spaces can be hard to clean. Blockages may occur easily, affecting performance.

Moreover, the exchangers are compact. They require less space compared to shell and tube designs. But, their high-pressure capabilities could lead to failures if not monitored. Ensuring proper maintenance is essential. This need for upkeep reflects a common oversight in usage. Users must weigh efficiency against maintenance needs.

Brazed plate heat exchangers (BPHE) and traditional heat exchangers serve similar functions but differ significantly in design. BPHEs consist of thin plates that are brazed together. This design increases surface area while reducing the amount of fluid required for effective heat transfer. In contrast, traditional heat exchangers often use larger and bulkier components. Their size can result in increased material costs and weight.

One notable advantage of BPHEs is their efficiency. They offer better heat transfer rates in a compact size, which is particularly beneficial in space-constrained applications. However, they may not handle very high-pressure situations as well as traditional models. Some users find that BPHEs can be less forgiving regarding maintenance. Their intricate design can complicate cleaning or repairs when necessary.

Maintenance can sometimes be a hurdle for those accustomed to older systems. Traditional heat exchangers often have simpler configurations, and users might prefer their straightforward repair processes. Despite their differences, both types of heat exchangers have unique benefits and challenges. Choosing between them requires careful consideration of application-specific requirements.

Brazed plate heat exchangers (BPHEs) are pivotal in thermal management across various industries.

These compact devices offer high efficiency and reliability.

Their design allows for effective heat transfer, which is essential in sectors like HVAC, refrigeration, and food processing.

According to recent industry reports, BPHEs can improve energy efficiency by up to 30%.

This is significant in reducing operational costs.

Using BPHEs offers several advantages. They occupy less space compared to traditional heat exchangers, making them ideal for tight environments.

Their ability to handle high pressures and temperatures is outstanding. In addition,

the brazing process ensures no leaks, enhancing safety and performance.

Industries can also benefit from lower maintenance costs,

as these devices require less frequent servicing.

Tips: Regularly check for any signs of wear and tear.

Although BPHEs are durable, they are not immune to issues.

Consider operational conditions carefully. High fouling or aggressive fluids can impact performance.

Investing in a robust monitoring system can prevent potential failures.

Brazed plate heat exchangers (BPHEs) are compact and highly efficient devices used in various industries. Their applications span HVAC, food processing, and chemical production. For example, in the HVAC sector alone, BPHEs can improve system efficiency by up to 30%, according to a recent report by the International Energy Agency.

These heat exchangers excel in sectors requiring precise temperature management. In food processing, BPHEs ensure consistent heat transfer and safety standards. They can handle high pressures, which is crucial for applications like pasteurization. Yet, some users find maintenance challenging. The design may not allow easy access for cleaning. Regular inspections are essential to prevent failure.

Performance metrics indicate BPHEs have a thermal efficiency of up to 95%. This high performance often compensates for initial costs over time. However, the material fatigue in high-temperature applications raises concerns. Users must consider the operating conditions carefully. Understanding these factors helps companies maximize benefits while addressing potential drawbacks.