Leave Your Message

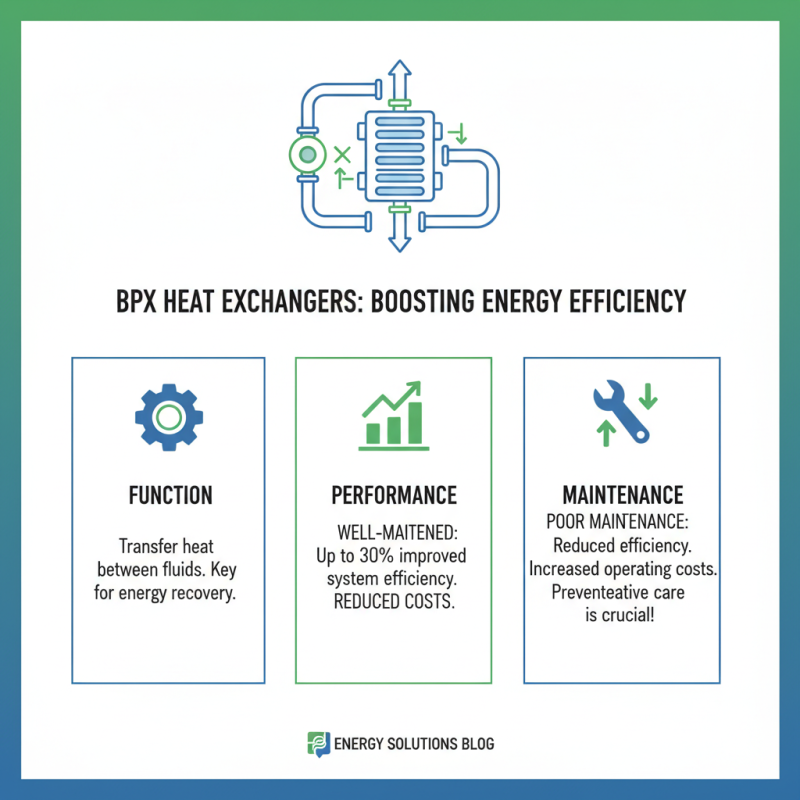

In the world of thermal management, the Bpx Heat Exchanger plays a crucial role. Industry expert Dr. Emily Harper once stated, "Maximizing efficiency in heat exchangers requires careful attention to design and operation." This highlights the importance of understanding how to optimize these systems.

Bpx Heat Exchangers are essential in various applications, from industrial processes to HVAC systems. However, many realize that poor maintenance leads to inefficiencies. A simple oversight can significantly impact performance. Regular cleaning and inspection are often neglected.

To achieve optimal performance, it's vital to assess flow rates and temperature differentials. Efficiency metrics should be tracked, but many teams overlook this data. Understanding your system's unique needs is key. Adapting to these needs can boost overall efficiency. A proactive approach can reveal flaws that were previously unnoticed.

Bpx heat exchangers play a crucial role in maximizing energy efficiency across various industries. These devices transfer heat between two or more fluids effectively. According to a recent study, well-maintained heat exchangers can improve a system's efficiency by up to 30%. However, improper maintenance can lead to performance issues, costing businesses substantially.

Understanding the basics is essential. Bpx heat exchangers work on the principle of thermal conduction. They allow one fluid to absorb heat from another without mixing. This principle is vital for processes like cooling and heating in HVAC systems, chemical plants, and food processing. Yet, even slight inefficiencies, like fouling, can reduce heat transfer rates significantly.

Regular inspection and cleaning are necessary to maintain optimal function. Data suggests that routine maintenance can extend the lifespan of heat exchangers by 20%. Still, many overlook regular checks. They wait until a problem arises, which often leads to costly downtime. Awareness and proactive measures are key to ensuring long-term efficiency and performance.

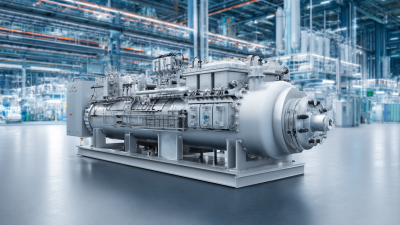

Heat exchangers play a crucial role in various industrial applications. Their efficiency can significantly affect overall system performance. Several key factors influence how well a heat exchanger performs. Understanding these factors is vital for optimal operation.

One major factor is the design of the heat exchanger. The surface area available for heat transfer is critical. Larger areas typically enhance efficiency. However, larger units can be less manageable and may require more maintenance, leading to operational challenges. The flow arrangement also matters. Counterflow designs usually outperform parallel flow units, but each has its disadvantages.

Another essential aspect is the working fluid. The properties of the fluids involved, such as viscosity and thermal conductivity, affect heat transfer rates. A fluid with high thermal conductivity will transfer heat more efficiently. However, using such fluids may have other drawbacks, like higher costs.

Regular maintenance is also vital. Deposits can accumulate and reduce efficiency. Neglecting routine checks can lead to unexpected failures and inefficiencies. Addressing these issues requires continuous monitoring and adjustment.

Maintaining a heat exchanger is crucial for its efficiency. Regular cleaning is key. A dirty heat exchanger can reduce performance by up to 30%. This leads to higher energy costs and lower output. Inspections should occur quarterly. They help identify issues early, preventing costly repairs.

Check seals for wear and tear. A failure here can cause refrigerant leaks. Such leaks can reduce efficiency and harm the environment. Pressure imbalances should also be monitored. They can signal blockages or malfunctions. Addressing these issues promptly is vital.

Vibration analysis can be useful too. Unusual vibrations often indicate mechanical problems. Regular monitoring can catch these early. Training staff on proper maintenance practices is essential. Knowledge gaps can lead to errors. Remember, a well-maintained heat exchanger not only saves money but also enhances system longevity.

In optimizing heat exchangers, specific applications require tailored designs. Not all designs suit every industrial process. Research shows that optimizing the thermal performance can boost efficiency by as much as 30%. This can significantly impact energy costs and operational efficiency.

When designing for specific applications, consider fluid flow rates. High flow rates may require larger surface areas for heat transfer. A study indicated that a 10% increase in the heat transfer surface area improves efficiency by 15%. Regular maintenance schedules can help identify design flaws early. Addressing them can prevent downtime.

Tips to enhance performance include selecting the right materials that withstand corrosive environments. Evaluate the surrounding conditions, too. Consider temperature fluctuations in application settings. Additionally, monitor the system regularly to ensure it operates within desired parameters. Small adjustments can lead to substantial efficiency gains. Furthermore, reflect on past performance issues. Understanding these can inform better designs and practices moving forward.

This bar chart illustrates the efficiency percentages of different heat exchanger applications. The data highlights how specific designs can be optimized for tailored performance in diverse operational conditions.

Heat exchangers play a critical role in various industrial processes. However, they often face issues that can hinder their efficiency. Common problems include fouling, leakage, and suboptimal heat transfer. According to industry reports, fouling can decrease efficiency by up to 30%, leading to significant operational losses. Regular maintenance is crucial. Neglecting it can escalate minor issues into major failures.

Leakage poses another challenge. A small leak can disrupt the entire process. It can also lead to costly downtimes. Inspecting seals and joints should be a routine practice. Additionally, monitoring pressure drops helps identify potential problems before they escalate.

Temperature imbalances might also occur. These can indicate a malfunction in the system. A reported 15% of heat exchangers exhibit temperature inconsistencies. This often suggests mistranslation in design or improper installation. Addressing these concerns early can prevent long-term damage. Operators must continuously evaluate performance metrics, ensuring each component functions optimally.

| Issue | Description | Potential Causes | Recommended Solutions | Preventive Measures |

|---|---|---|---|---|

| Inefficient Heat Transfer | Heat exchanger not transferring heat effectively. | Fouling, incorrect flow rates. | Clean regularly, adjust flow rates. | Routine maintenance and inspections. |

| Leaking | Fluid leaks observed. | Corrosion, wear, mechanical failure. | Identify source, repair or replace. | Inspect seals and joints regularly. |

| Pressure Drop | Excessive pressure loss in the system. | Clogged passages, poor design. | Check and clear blockages, redesign if needed. | Flow analysis during design phase. |

| Noise | Unusual sounds from operation. | Vibration, liquid hammer. | Check mounting, control flow rates. | Install silencing equipment. |

| Temperature Fluctuations | Inconsistent temperature in the outlet. | Variable flow, control issues. | Stabilize flow rates, recalibrate controls. | Implement control systems properly. |