Leave Your Message

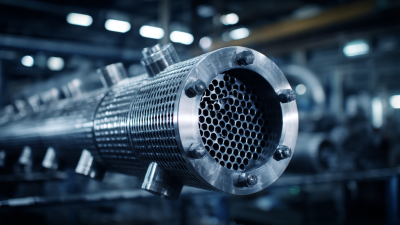

The Bpx Heat Exchanger represents a significant advancement in thermal management technology, offering a variety of benefits across multiple industries. As energy efficiency becomes increasingly crucial for businesses facing rising operational costs, the innovation behind the Bpx Heat Exchanger is gaining attention for its impressive performance and reliability. This device is designed to maximize heat transfer while minimizing energy loss, making it an essential component in applications ranging from industrial manufacturing to HVAC systems.

In addition to its functionality, the Bpx Heat Exchanger boasts a range of key features that set it apart from traditional heat exchangers. With its compact design, enhanced resistance to corrosion, and ability to handle extreme temperature variations, the Bpx Heat Exchanger is not only versatile but also more durable. Understanding its various applications and the specific advantages it offers will provide valuable insights for engineers and decision-makers looking to optimize their systems for better efficiency and sustainability. This article delves deeper into the workings of the Bpx Heat Exchanger, highlighting its importance in modern engineering solutions.

A Bpx heat exchanger is a crucial technology designed to facilitate the transfer of heat between two or more fluids without mixing them. This equipment operates on the principle of thermal conduction, where heat moves from the warmer fluid to the cooler one through a series of metal plates or tubes. Typically constructed from high-conductivity materials such as stainless steel or aluminum, Bpx heat exchangers enhance thermal efficiency and can be found in various applications, including HVAC systems, refrigeration, and industrial processes.

The advantages of Bpx heat exchangers are significant. They provide improved energy efficiency, helping facilities reduce operational costs while minimizing environmental impact. In addition, their compact design allows for easy installation in space-constrained environments. These heat exchangers also contribute to consistent temperature control, which is vital for maintaining process integrity in industries such as food and beverage, pharmaceuticals, and chemical processing. As the push for sustainability in industrial practices grows, Bpx heat exchangers are becoming an integral component of eco-friendly technologies.

| Dimension | Details |

|---|---|

| Type | Plate Heat Exchanger |

| Material | Stainless Steel |

| Efficiency | Up to 95% |

| Temperature Range | -20°C to 180°C |

| Applications | Food Processing, HVAC, Chemical Industries |

| Benefits | Compact Design, High Efficiency, Versatile |

| Key Features | Easy Maintenance, Customizable Sizes, Corrosion Resistance |

Bpx heat exchangers are gaining attention across various industries due to their efficient thermal management capabilities. One of the key benefits of these systems is their compact design, which allows for space-saving configurations and easier installation in heating and cooling applications. As energy demands rise, particularly in heavy-duty industrial operations, the Bpx heat exchangers offer enhanced performance that aligns with growing infrastructure needs.

The market for plate heat exchangers, which includes Bpx models, is expected to witness substantial growth, projected to increase from $6.5 billion in 2024 to $10.52 billion by 2032, with a CAGR of 6.2%. This surge is driven by the necessity for efficient heat transfer solutions in various sectors, including food processing, pharmaceuticals, and HVAC. Additionally, the air-cooled heat exchanger market is forecasted to reach $10.3 billion by 2035, highlighting the robust demand for advanced heat exchange technologies. With features such as improved energy efficiency and reduced maintenance costs, Bpx heat exchangers stand to significantly benefit organizations looking to optimize their operational efficiency while adhering to sustainability goals.

Bpx heat exchangers are becoming increasingly essential in modern technology, serving a wide variety of applications across multiple industries. One significant application is in HVAC systems, where these exchangers facilitate efficient temperature regulation, ensuring optimal comfort in commercial and residential buildings. Their ability to reclaim waste heat leads to notable energy savings and enhanced environmental sustainability.

In the chemical processing sector, Bpx heat exchangers play a crucial role in managing thermal energy during various reactions. They enable precise temperature control, which is vital for maintaining product quality and optimizing reaction rates. Additionally, in the power generation industry, these heat exchangers are employed in both fossil fuel and renewable energy plants to enhance thermal efficiency, improving overall productivity and reducing operational costs. The versatility and efficacy of Bpx heat exchangers make them indispensable in advancing technological efficiency across numerous fields.

BPX heat exchangers are increasingly recognized in various industries for their distinctive features that enhance performance and efficiency. One of the essential features is their advanced thermal design, which maximizes heat transfer efficiency. According to a recent report by the Heat Transfer Research Institute, the innovative design of BPX exchangers can improve heat transfer rates by up to 30% compared to traditional models, leading to significant energy savings for operators.

Another standout characteristic is their corrosion resistance. BPX heat exchangers are often constructed from advanced materials that withstand harsh environments, reducing the likelihood of system failures and maintenance costs. Industry data indicates that equipment failure due to corrosion can account for roughly 40% of total operational downtime in chemical processing plants. By employing BPX heat exchangers, facilities can effectively lower this risk.

Moreover, BPX heat exchangers are designed for enhanced modularity, allowing them to be easily integrated into existing systems. This flexibility is particularly beneficial in industries like food and beverage, where process adaptation is crucial. The ability to customize configurations not only supports different applications but also optimizes operational performance, aligning with the growing trend for energy-efficient solutions in manufacturing.

The Bpx heat exchanger is gaining traction as a highly efficient alternative to traditional heat exchanger options such as shell-and-tube or plate type heat exchangers. One of the most significant benefits of Bpx heat exchangers is their ability to enhance thermal performance while reducing energy consumption. According to a recent industry report by TechSci Research, Bpx heat exchangers can result in energy savings of up to 25% compared to conventional models due to their unique design and materials used.

When comparing Bpx heat exchangers to traditional options, it is important to consider their compact size and adaptability. Traditional heat exchangers often require substantial installation space and may not fit well in retrofitting situations. In contrast, Bpx models are designed with a modular approach, making them suitable for a range of applications, from chemical processing to HVAC systems. This versatility can lead to substantial cost savings in both installation and maintenance.

Tips: When selecting a heat exchanger, consider the specific thermal requirements of your application. Additionally, assess the available installation space to determine if a Bpx heat exchanger’s compact design will benefit your project. Lastly, always consult industry data to benchmark performance metrics against your current systems to make informed decisions.