Leave Your Message

In the realm of thermal management, the Bpx Heat Exchanger has emerged as a crucial component across various modern applications. Renowned industry expert Dr. Emily Hartman has noted, "The Bpx Heat Exchanger not only enhances energy efficiency but also plays a pivotal role in reducing operational costs for companies worldwide." This innovative heat exchanger is designed to optimize heat transfer between two or more fluids, making it an essential element in sectors ranging from manufacturing to power generation.

As industries increasingly seek sustainable solutions to manage energy consumption, the Bpx Heat Exchanger stands out for its advanced design and functionality. Its ability to handle high temperatures and pressures while maintaining efficiency has made it a preferred choice among engineers and energy managers. By facilitating the efficient transfer of heat, this technology not only improves system performance but also contributes to environmental sustainability, reducing carbon footprints in various sectors.

Understanding how the Bpx Heat Exchanger operates and its applications can provide valuable insights for professionals looking to enhance efficiencies in their systems. In this discussion, we will explore the mechanisms behind this technology and its wide-ranging implications in today’s energy-driven world.

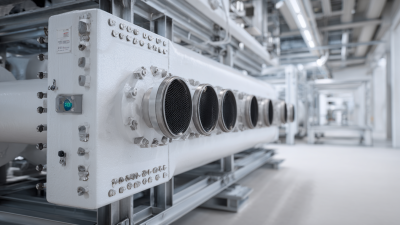

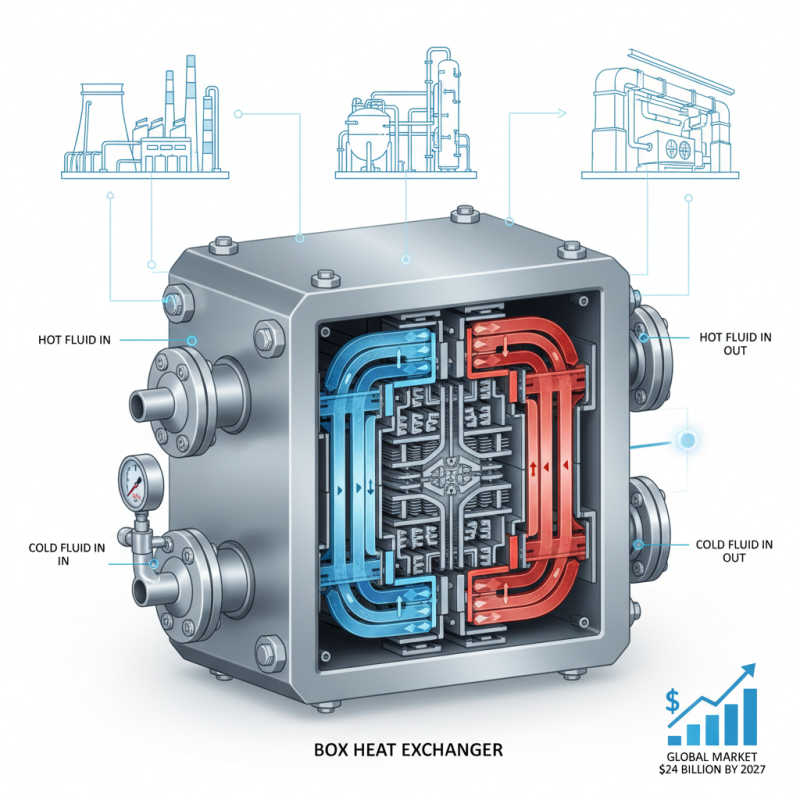

A box heat exchanger is a type of heat exchanger that is designed in a compact box-like structure, optimizing space and efficiency in a variety of applications. It typically consists of two or more fluid streams that flow through separate channels or plates, allowing heat to transfer between them without mixing. This design is particularly advantageous in systems where space is limited or where a high level of heat transfer is required, such as in HVAC systems, industrial processes, and energy systems.

The operational principle of a box heat exchanger hinges on the concept of thermal conductivity. As one fluid passes through the exchanger, it absorbs heat from or transfers heat to another fluid flowing through adjacent channels. The materials used in the box heat exchanger are chosen for their thermal efficiency and resistance to corrosion, ensuring prolonged performance and reliability. The modularity of the box design allows for easy maintenance and scalability, making it a preferred choice in modern engineering applications where energy efficiency and compact design are critical.

| Dimension | Description | Application | Efficiency |

|---|---|---|---|

| Design | Compact and modular design, improving space utilization. | Industrial heating and cooling processes. | High thermal efficiency (up to 90%). |

| Material | Typically made from stainless steel and titanium. | Chemical processing environments. | Enhanced corrosion resistance. |

| Maintenance | Requires regular cleaning to maintain efficiency. | Power generation and HVAC systems. | Low maintenance costs compared to traditional exchangers. |

| Applications | Used in refrigeration, heating, and cooling applications. | Food and beverage processing. | High reliability in thermal transfer. |

| Performance | Handles high pressures and temperatures. | Oil and gas processing. | Consistent performance metrics under load. |

A Box Heat Exchanger (Bpx) is a highly efficient thermal management system designed to transfer heat between two or more fluids. Its operation is based on the principles of thermal conductivity and fluid dynamics. Typically, a Bpx consists of a series of plates or tubes arranged to facilitate maximum surface area contact between the fluids while minimizing mix and contamination. The design allows fluids to flow in counter-current or crossflow arrangements, enhancing the heat transfer process. Reports indicate that Bpx heat exchangers can achieve thermal efficiencies of over 90%, making them a preferred choice in industries such as chemical processing, power generation, and HVAC systems.

A Box Heat Exchanger (Bpx) is a highly efficient thermal management system designed to transfer heat between two or more fluids. Its operation is based on the principles of thermal conductivity and fluid dynamics. Typically, a Bpx consists of a series of plates or tubes arranged to facilitate maximum surface area contact between the fluids while minimizing mix and contamination. The design allows fluids to flow in counter-current or crossflow arrangements, enhancing the heat transfer process. Reports indicate that Bpx heat exchangers can achieve thermal efficiencies of over 90%, making them a preferred choice in industries such as chemical processing, power generation, and HVAC systems.

One of the key design features of a Bpx is its modularity, which allows for easy scaling and maintenance. The compact nature enables installations in confined spaces without sacrificing performance. Additionally, advancements in material technology have led to the use of corrosion-resistant alloys, extending the lifespan and reliability of heat exchangers. According to recent industry analyses, the global heat exchanger market is projected to grow at a CAGR of 6% through the next five years, driven by the increasing demand for energy efficiency and sustainability in industrial processes.

Tips: When selecting a Bpx heat exchanger, consider factors such as fluid properties, required temperature differentials, and maintenance accessibility. Regular inspection and cleaning are essential to ensure optimal performance and avoid fouling, which can significantly impact efficiency. Additionally, utilizing simulation software for thermal and fluid flow analysis can provide deeper insights into the system's design and performance characteristics, leading to well-informed decisions.

Box heat exchangers are widely utilized in various industries due to their efficient thermal performance and compact design. The effectiveness of these systems is largely dependent on the materials used in their construction. Common materials for box heat exchangers include stainless steel, carbon steel, copper, and aluminum, each offering distinct advantages for different applications.

Stainless steel is one of the most popular choices due to its excellent corrosion resistance, strength, and high-temperature tolerance. This makes it ideal for processes involving aggressive fluids or high-pressure environments, ensuring longevity and reliability. Carbon steel, while more cost-effective, is often chosen for applications where the operating environment is less corrosive. On the other hand, copper is recognized for its superior thermal conductivity, making it suitable for situations requiring rapid heat transfer. Aluminum, being lightweight and resistant to corrosion, is used in specific scenarios where weight reduction and efficiency are priorities.

Choosing the right material for a box heat exchanger is essential to optimize performance and durability. Each material's specific properties allow engineers to tailor heat exchanger designs to fit the operational needs, ensuring that the systems are efficient and reliable in modern applications.

Box heat exchangers have become essential in various modern industries due to their efficient thermal management capabilities. Commonly utilized in power generation, chemical processing, and HVAC systems, these devices improve energy efficiency by facilitating effective heat transfer between two fluids. According to a report by Grand View Research, the global market for heat exchangers is expected to reach $24 billion by 2027, highlighting their growing importance in industrial applications.

In the power generation sector, box heat exchangers are employed to recover waste heat from exhaust gases, allowing facilities to enhance energy output while minimizing fuel consumption. The chemical industry also benefits from these systems, where precise temperature control is critical for optimal reactions. Data from the International Energy Agency reveals that implementing advanced heat exchange solutions can reduce energy costs by up to 30%, making these systems not just environmentally friendly but also economically advantageous.

Tips: Ensure proper sizing and design of box heat exchangers to maximize efficiency and minimize fouling, which can lead to significant performance losses. Regular maintenance is crucial for sustaining optimal operation and extending the lifespan of the equipment. Implementing real-time monitoring systems can help in identifying potential issues early on, thus preventing costly downtimes.

Box heat exchangers are widely utilized in modern applications due to their unique advantages, primarily in thermal efficiency and compact design. One of the key benefits of a box heat exchanger is its ability to handle large volumes of fluid while maintaining a small footprint. This design allows for easy integration into existing systems, making them suitable for a variety of industries, including HVAC, chemical processing, and food production. Additionally, their modular nature enables straightforward maintenance and cleaning, which is crucial in environments requiring stringent hygiene standards.

However, box heat exchangers also have limitations that must be considered. They can be more expensive to manufacture compared to traditional heat exchangers, leading to higher initial investment costs. Moreover, their efficiency can be impacted by the potential for fouling, where deposits build up on the heat transfer surfaces, reducing performance over time. Proper maintenance and regular cleaning schedules are essential to mitigate this issue. Furthermore, box heat exchangers may not perform as effectively in extreme temperature or pressure conditions, which could restrict their application in certain high-demand scenarios. Balancing these advantages and limitations is vital for organizations looking to optimize their thermal management systems.