Leave Your Message

In today's increasingly interconnected global market, the sourcing of Plate Exchangers has become a crucial factor for businesses aiming to enhance their operational efficiency and sustainability. According to a report by MarketsandMarkets, the global heat exchanger market is projected to reach USD 23.8 billion by 2026, with Plate Exchangers accounting for a significant portion of this growth due to their compact design and superior thermal transfer capabilities. As industries ranging from oil and gas to food processing seek to optimize their thermal management solutions, understanding the best practices for sourcing these essential components is more important than ever. This comprehensive guide will explore seven key strategies that can help companies navigate the complexities of global sourcing, ensuring they select the right Plate Exchangers for their unique applications while maintaining cost-effectiveness and reliability.

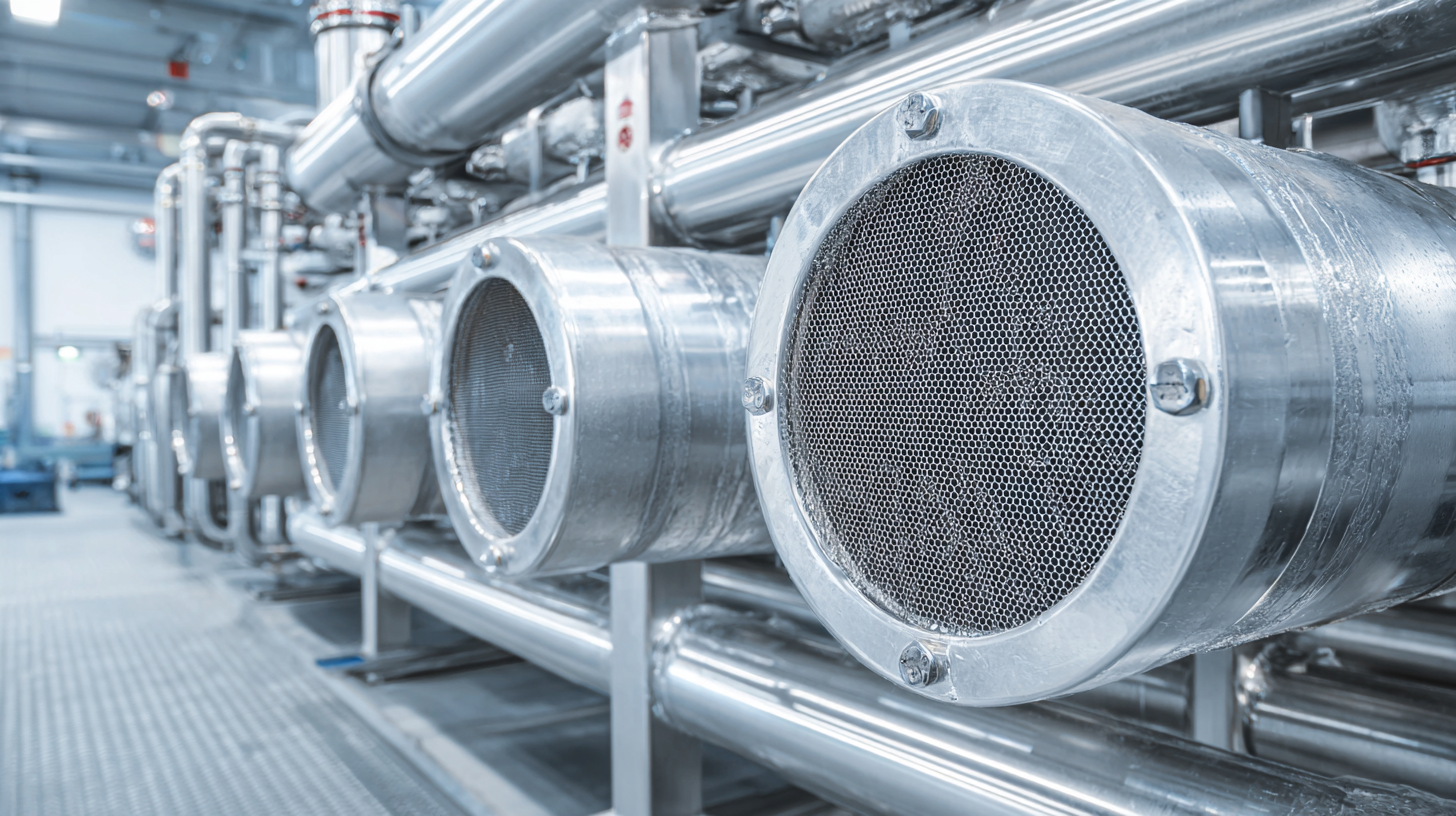

Plate heat exchangers (PHEs) play a pivotal role in various global industries, from oil and gas to food processing and HVAC systems.

According to a report by Markets and Markets, the global plate heat exchanger market is projected to reach approximately

$4.16 billion by 2026, growing at a CAGR of 8.5% from 2021. This growth highlights the increasing dependency of industries on efficient heat transfer solutions to

optimize processes, reduce energy consumption, and minimize environmental impact.

Plate heat exchangers (PHEs) play a pivotal role in various global industries, from oil and gas to food processing and HVAC systems.

According to a report by Markets and Markets, the global plate heat exchanger market is projected to reach approximately

$4.16 billion by 2026, growing at a CAGR of 8.5% from 2021. This growth highlights the increasing dependency of industries on efficient heat transfer solutions to

optimize processes, reduce energy consumption, and minimize environmental impact.

In the energy sector, PHEs are crucial for improving efficiency in energy recovery systems and maintaining optimal operating temperatures. For instance, in the oil and gas industry, plate heat exchangers are used in cooling, heating, and condensing applications, enhancing the operational performance of plants and contributing to sustainability efforts. As industries continually seek innovative solutions that align with global sustainability goals, the demand for efficient and reliable plate heat exchangers is expected to surge, driving advancements in technology and design.

When sourcing plate heat exchangers on a global scale, several key factors significantly influence decision-making. Firstly, the material quality plays a crucial role, as plate heat exchangers are often exposed to extreme temperatures and corrosive environments. According to a 2022 market analysis by Grand View Research, the demand for durable and efficient materials like titanium and stainless steel has surged, contributing to a projected market growth rate of 8.5% from 2023 to 2030. Sourcing manufacturers that adhere to international quality standards, such as ISO and ASME, ensures that the equipment will withstand rigorous demands.

Another important factor is the technological advancement of the manufacturers. The integration of advanced manufacturing technologies, such as laser welding and 3D printing, has improved the efficiency and performance of plate heat exchangers. A study conducted by Research and Markets found that innovations in design, including compact and lightweight exchanger models, can enhance thermal performance by up to 30%. Furthermore, understanding regional regulations and compliance requirements is vital, as local standards can vary significantly. Companies that navigate these complexities effectively are better positioned to secure high-quality products that meet both performance and regulatory benchmarks.

When sourcing plate exchangers on a global scale, evaluating suppliers is a pivotal component that can significantly impact operational efficiency and product quality. Establishing critical benchmarks and performance metrics is essential to ensure the chosen supplier aligns with your organizational needs and expectations. Factors such as delivery time, product durability, and compliance with industry standards should be systematically measured. By creating a scorecard that includes these metrics, businesses can objectively assess potential suppliers and ensure that they meet the required specifications.

Moreover, effective communication plays a crucial role in the evaluation process. Engaging suppliers in discussions about their production capabilities and quality assurance processes can help identify any potential red flags early on. Additionally, exploring customer feedback and case studies can provide insights into the supplier's performance history. Understanding how they respond to challenges and their approach to innovation can further guide decisions. By implementing a thorough and systematic evaluation strategy, sourcing plate exchangers from global suppliers can lead to fruitful partnerships and enhanced product performance.

| Supplier Criteria | Benchmark | Performance Metrics | Rating (1-5) | Notes |

|---|---|---|---|---|

| Quality Assurance | ISO Certification | Pass rate of 95%+ | 5 | Excellent certifications |

| Delivery Time | Lead Time | Average 4 weeks | 4 | Consistent delivery |

| Cost Competitiveness | Price Quotations | 10% below market average | 4 | Good value |

| Technical Support | Availability | 24/7 support | 5 | Responsive team |

| Innovative Design | R&D Investment | 10% of revenue | 4 | Strong focus on innovation |

| Customer Feedback | Satisfaction Surveys | 80% positive feedback | 4 | Generally positive |

| Environmental Compliance | Regulatory Adherence | 100% compliance | 5 | Very responsible |

When sourcing plate exchangers globally, understanding and navigating regulatory compliance is crucial to ensure a seamless procurement process. Different countries have distinct regulations regarding manufacturing standards, material safety, and environmental impact. It is imperative to familiarize yourself with these local laws before entering new markets. This not only helps in avoiding legal pitfalls but also enhances the credibility of your sourcing operations. Engaging with local compliance experts can provide valuable insights and keep you updated on any changes in regulations.

Moreover, establishing strong relationships with suppliers is essential. Reliable suppliers will be well-versed in compliance requirements and can guide you through the complexities of the regulations applicable to their countries. Collaborating with them can streamline documentation processes, ensuring that all necessary certifications are in place for your plate exchangers. Additionally, consider leveraging technology for better compliance management. Online platforms can help track regulatory changes and maintain an organized repository of documentation, ultimately simplifying the sourcing process while adhering to mandatory standards.

In the ever-evolving landscape of sourcing plate exchangers, leveraging technology can significantly enhance efficiency and streamline operations. Digital tools like advanced analytics and cloud-based systems allow companies to capture real-time data, making the sourcing process more responsive to market trends and demand fluctuations. By implementing an integrated software solution, organizations can gain insights that lead to better decision-making and reduced lead times.

Tip: Utilize automated procurement platforms to facilitate the sourcing process. These platforms can help you quickly compare suppliers, track inventory levels, and manage supply chain risks more effectively. Automation minimizes manual errors and accelerates the overall procurement cycle, allowing teams to focus on strategic tasks.

Another avenue to explore is the use of artificial intelligence (AI) in supplier selection. AI can analyze vast amounts of data to identify the most reliable suppliers and predict potential challenges in the sourcing process. This proactive approach reduces downtime and ensures a consistent supply of quality plate exchangers.

Tip: Invest in AI-driven analytics to assess supplier performance over time. By continuously monitoring key performance indicators, businesses can make informed choices about partnerships, fostering a more resilient sourcing strategy in a competitive global market.