Leave Your Message

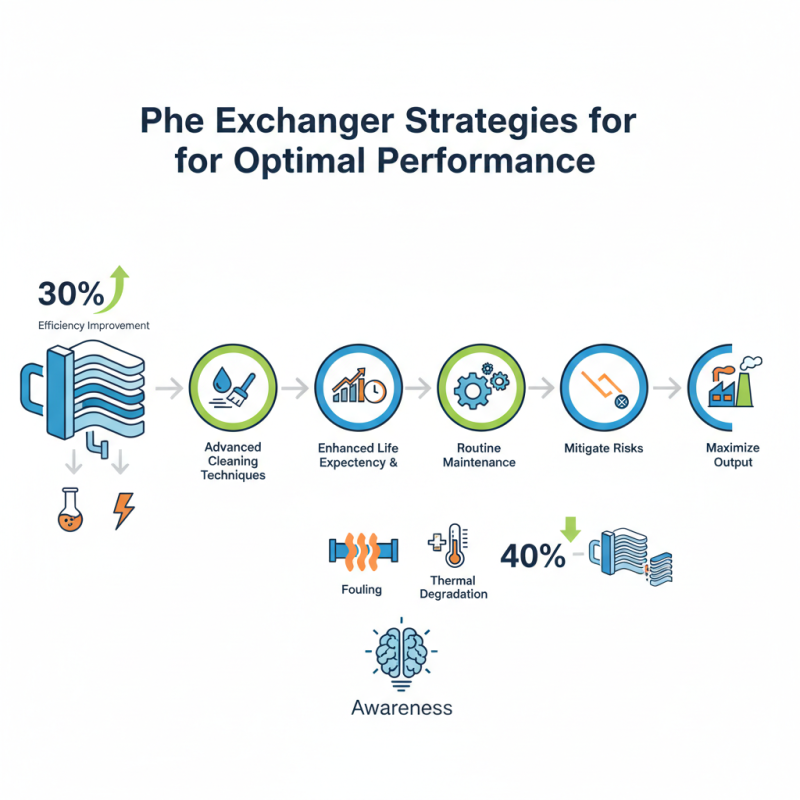

The performance of Phe Exchanger systems plays a critical role in various industries, especially in chemical processing and energy production. Recent studies have shown that optimizing these systems can lead to efficiency improvements of up to 30%. This change is significant as industries increasingly focus on sustainability and energy conservation.

Phe Exchangers handle thermal energy transfer in various applications. However, many structures face challenges, such as fouling and thermal degradation. Reports indicate that nearly 40% of heat exchangers in operation suffer from efficiency loss due to these issues. Companies must address performance gaps to maintain competitiveness.

Investing in the best Phe Exchanger strategies can mitigate risks and maximize output. For instance, employing advanced cleaning techniques can enhance life expectancy and reliability. However, organizations often overlook routine maintenance, which can lead to costly downtimes. Becoming aware of these factors is crucial for anyone involved in heat exchange systems.

The significance of plate heat exchangers (PHE) technology in industrial processes cannot be overstated. PHE units excel in transferring heat efficiently between fluids. They occupy less space than traditional methods, making them ideal in cramped environments. Their modular design allows for easy scaling and maintenance, enhancing operational flexibility.

In various industries, such as food processing and HVAC, PHE technology is pivotal. However, the choice of materials and design can impact performance. Some manufacturers overlook material compatibility, which may lead to corrosion. This oversight can drastically reduce efficiency and lifespan.

Understanding the specific heat transfer requirements is crucial for optimal performance. Moreover, proper maintenance of PHE systems is often neglected. Regular checks can prevent blockages and scaling. These issues can disrupt fluid flow and lead to costly downtimes. Operators must reflect on past maintenance practices to improve reliability.

By addressing these challenges, industries can harness the full potential of PHE technology.

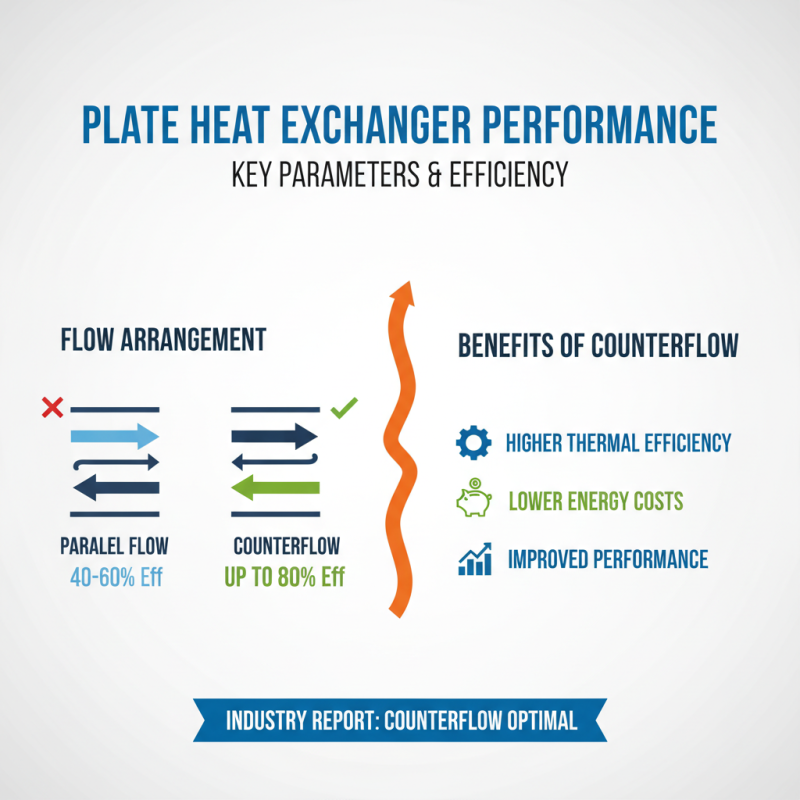

The performance of plate heat exchangers (PHEs) is heavily influenced by various key parameters. The flow arrangement is critical. Counterflow designs often yield better thermal efficiency than parallel flow. In a recent industry report, it was stated that counterflow configurations can achieve up to 80% efficiency in certain applications. This efficiency gain can significantly lower energy costs.

Another important factor is the temperature difference between the two fluids. A larger temperature gap typically enhances heat transfer rates. Nevertheless, cooling and heating demands may not always allow for such variations. In many cases, the optimal temperature difference is often missed, leading to reduced performance.

The material of the plates also plays a significant role. Stainless steel offers excellent corrosion resistance, but it's more expensive. Meanwhile, alternatives like titanium present affordability issues. Each material choice comes with its own pros and cons, requiring careful consideration. A mismatch can lead to severe efficiency drops. It's essential to assess not only the operational conditions but also long-term reliability. Maintaining an optimal PHE configuration demands ongoing attention to these parameters to truly maximize performance.

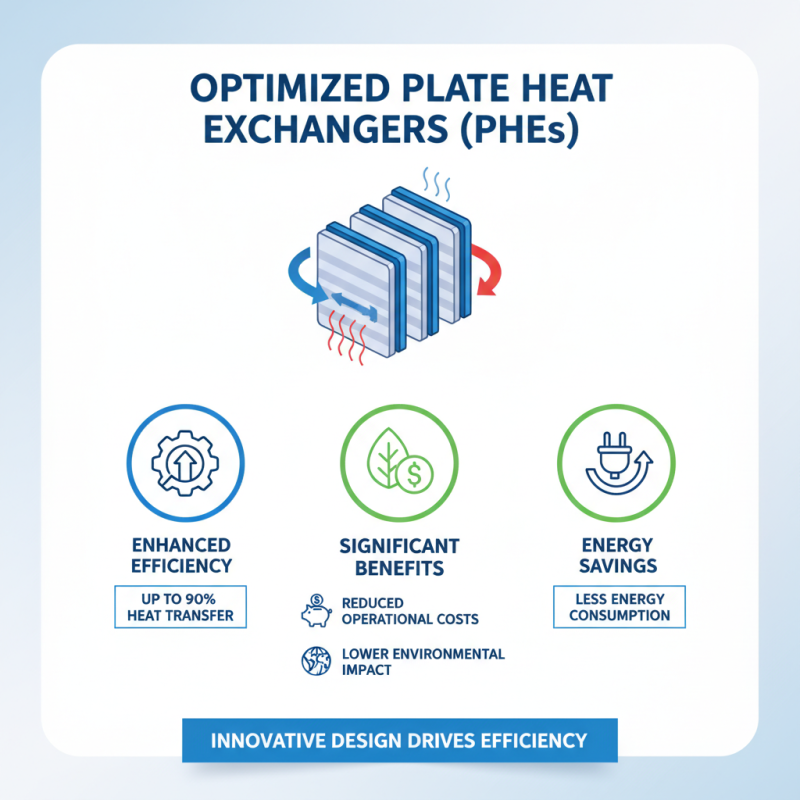

The efficiency of plate heat exchangers (PHEs) hinges on innovative design approaches. Enhanced thermal efficiency can lead to significant energy savings. According to industry reports, optimized PHEs can achieve up to 90% thermal transfer efficiency. This translates to reduced operational costs and lower environmental impact.

One effective strategy involves fine-tuning the plate geometry. Adjusting the corrugation pattern can improve fluid dynamics. Studies show that a redesigned corrugation angle can boost heat transfer rates by 30%. However, it’s crucial to balance this with pressure drop, as excessive turbulence can lead to increased pumping costs. Mistakes in design can negate efficiency gains.

Another important aspect is material choice. Many manufacturers are opting for advanced materials that provide higher heat resistance and durability. Yet, even high-performance materials can face challenges in specific applications. In some cases, unexpected fouling can require frequent maintenance and cleaning. Evaluating long-term performance remains essential in selecting materials. Embracing these innovative strategies demands both creativity and caution in the pursuit of optimal performance in PHEs.

Fouling is a persistent issue in heat exchangers. It reduces efficiency and increases maintenance costs. Understanding the factors that contribute to fouling is essential. Fouling can occur due to scale, biological growth, and sediment accumulation. Regular cleaning schedules are crucial for optimal performance. However, achieving the perfect cleaning routine is challenging. Sometimes, cleaning might not address all fouling types effectively.

Maximizing heat transfer requires a careful balance. Turbulence in fluid flow can enhance heat transfer rates. Yet, increased turbulence may also lead to higher fouling rates. Adjusting flow rates can help achieve this balance. Monitoring temperature differences between inlet and outlet can provide insights on performance. Small adjustments can yield significant improvements. Operators need to be vigilant. Addressing minor fouling issues early can prevent larger problems.

Using advanced materials for heat exchangers is another strategy. Some materials resist fouling better than others. However, the choice of materials is not always straightforward. High-performance materials may come with higher costs. Operators might need to weigh costs against potential benefits. Experimentation with different configurations could yield better results. It's a process of trial and learning.

Case studies highlight the effective implementation of PHE optimization techniques. Many industries have achieved success by applying innovative strategies. For example, one company improved energy efficiency by optimizing flow rates. This not only reduced costs but also enhanced overall performance.

Another case involved adjusting the temperature approach in a heat exchanger system. The adjustments led to significant energy savings, yet the team learned the importance of continuous monitoring. Neglecting this aspect caused some initial setbacks. Real-time data can inform better decisions and prevent operational issues.

Additionally, integrating advanced analytics provided deeper insights. One facility utilized predictive maintenance, which decreased downtime. However, it took time to train staff on new processes. Implementing changes should consider employees' adaptability and skill levels. These reflections suggest that embracing change is vital, but challenges will arise.