Leave Your Message

In the world of marine engineering, efficiency is key. "A well-designed Marine Heat Exchanger can make all the difference," says Dr. Emily Carter, a leading expert in marine cooling systems. The importance of choosing the right heat exchanger is undeniable. It directly impacts vessel performance and operational costs.

Marine Heat Exchangers play a crucial role in cooling systems for boats and ships. They ensure engines do not overheat, improving safety and longevity. Selecting the best models can be challenging. Numerous options exist, each with unique benefits and drawbacks.

Many overlook the need for regular maintenance and upgrades. Ignoring this can lead to inefficiencies or even failure. The landscape of marine heat exchangers is evolving. New technologies emerge, offering better performance and environmental sustainability. In this article, we explore the ten best marine heat exchangers available today, highlighting their features and advantages.

Marine heat exchangers play a crucial role in maintaining efficient cooling systems within marine vessels. These devices transfer heat from one fluid to another, ensuring optimal temperatures for equipment and engines. A recent industry report highlighted that heat exchangers can improve thermal efficiency by up to 25%, reducing operational costs and emissions. Their efficient design is vital for long voyages, as they help in prolonging the lifespan of critical machinery.

The importance of selecting the right heat exchanger cannot be overstated. Size, material, and design all contribute to performance. For instance, improperly sized exchangers can lead to inadequate cooling and potential equipment failure. Industry trends indicate that many marine operators overlook routine maintenance, which can further diminish heat exchanger efficiency. Regular inspections and cleaning can enhance performance, yet compliance with these practices is often inconsistent.

Improving cooling efficiency contributes to better fuel economy. Reports suggest that poor heat exchange could increase fuel consumption by 10%, impacting overall operating costs. Thus, investing in high-quality marine heat exchangers is not just a technical choice; it's a financial strategy. The industry faces challenges, including evolving regulations and environmental standards, making the choice of marine heat exchanger even more critical.

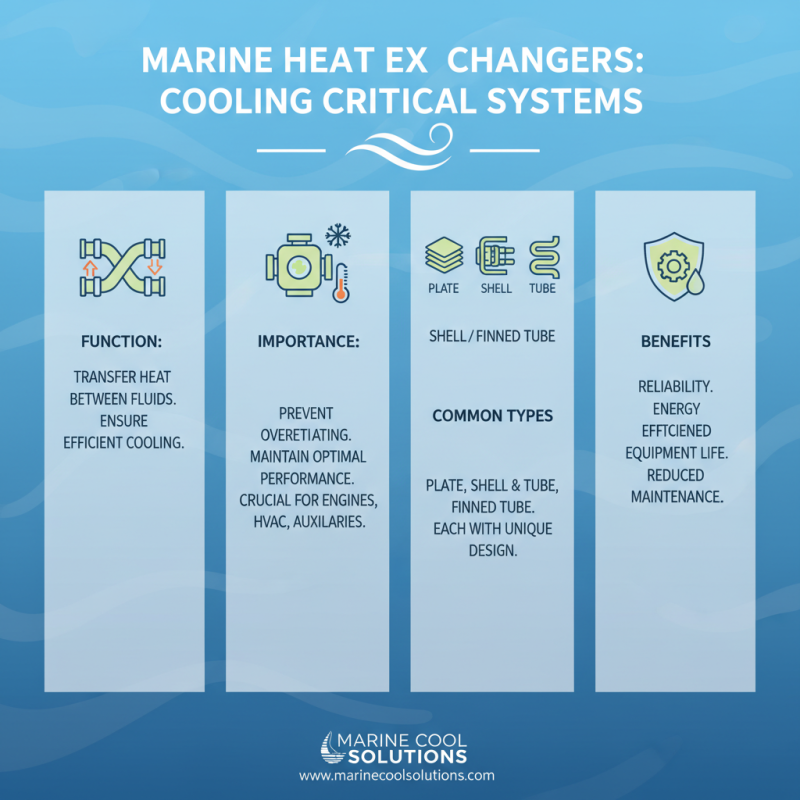

Marine heat exchangers play a crucial role in cooling systems. They transfer heat from one fluid to another, ensuring efficient cooling for various applications. There are several types of these exchangers, with each having its unique operational characteristics.

One popular type is the shell and tube heat exchanger. It features a series of tubes within a cylindrical shell. This design allows for effective heat transfer between the two fluids. Another type is the plate heat exchanger. Its flat plates maximize surface area, improving efficiency in a compact design. In some marine applications, air-cooled versions are also used, taking advantage of ambient air for cooling.

While these systems are widely used, issues can arise. For example, fouling can reduce efficiency over time. Regular maintenance is often overlooked, leading to potential failures. Additionally, some designs may not be optimal for specific marine conditions. Owners should assess their needs carefully before selecting a heat exchanger. Understanding these options helps ensure better performance in cooling systems.

When selecting a marine heat exchanger, several factors play a crucial role in ensuring efficiency. Size is key. A unit too small may not handle the heat load effectively. Conversely, an oversized unit can lead to higher costs and less efficient operation. According to a recent market analysis by the International Marine Institute, about 30% of marine operators reported inefficient cooling due to incorrect sizing.

Material choice is also vital. Common materials include titanium and copper-nickel alloys. Each has unique thermal conductivity and corrosion resistance properties. A study indicated that titanium heat exchangers could offer up to 20% better lifespan in seawater environments. However, these materials can be significantly more expensive. Thus, balancing cost and performance becomes essential for operators.

Maintenance is often overlooked yet crucial for longevity. Regular checks for fouling can maintain efficiency. Yet, many operators find themselves neglecting routine maintenance. A report noted that 25% of marine systems failed due to inadequate upkeep. Finding the right balance between maintenance schedules and operational demands is often a challenging task for fleet managers. Identifying issues early can save time and resources in the long run.

This chart displays the efficiency ratings of the top 10 marine heat exchangers based on various performance factors. The values represent the cooling capacity (in kW) and heat transfer area (in m²).

Marine heat exchangers play a crucial role in maintaining efficient cooling systems on vessels. They transfer heat between two or more fluids, keeping engines and machinery within optimal operating temperatures. Research indicates that the efficiency of these exchangers can enhance overall system performance by up to 30%. This significant improvement reduces energy consumption, which is essential for sustainability in marine operations.

When selecting a heat exchanger, consider the materials used. Corrosion-resistant materials can prolong the lifespan of the unit, especially in harsh marine environments. According to industry data, exchangers made from stainless steel or titanium show better resistance, increasing durability by 50% compared to standard options. Proper sizing and installation also play a role. Over-sizing can lead to inefficiencies, while under-sizing may result in overheating issues.

It's worth noting that maintenance is often overlooked. Regular cleaning and inspection can improve thermal efficiency. Ignoring these practices can lead to scaling and fouling, drastically reducing performance. In one study, nearly 70% of marine systems struggled because of inadequate upkeep. A proactive approach is essential for maximizing the benefits of marine heat exchangers.

Marine heat exchangers play a crucial role in cooling systems. Regular maintenance is key to keeping them running efficiently. Check the coolant levels frequently. Low coolant can lead to overheating. Make sure to inspect for leaks. Leaks can cause significant performance issues over time.

Cleaning is another vital aspect. Salt and debris can build up in the exchanger. Use fresh water to flush the system. This simple step can enhance performance. Additionally, watch for corrosion. Regularly inspect the materials for signs of wear. Address issues early to avoid costly repairs later.

Don't overlook the importance of expert servicing. Sometimes, self-checks aren't enough. An experienced technician can provide insights into potential problems. This helps maintain optimal performance. Ignoring signs can lead to serious setbacks. Always prioritize proper care and timely interventions.

| Model | Type | Cooling Capacity (BTU/hr) | Material | Dimensions (inches) | Weight (lbs) | Maintenance Tips |

|---|---|---|---|---|---|---|

| Model A | Shell and Tube | 100,000 | Copper | 20 x 10 x 15 | 50 | Regular cleanings every 6 months |

| Model B | Plate | 85,000 | Stainless Steel | 15 x 8 x 12 | 40 | Inspect gaskets annually |

| Model C | Air-Cooled | 70,000 | Aluminum | 22 x 11 x 13 | 35 | Clean fin surfaces regularly |

| Model D | Shell and Tube | 120,000 | Titanium | 18 x 9 x 14 | 55 | Check for leaks quarterly |

| Model E | Double-Pipe | 94,000 | Copper Nickel | 25 x 12 x 16 | 60 | Flush system seasonally |