Leave Your Message

In the ever-evolving landscape of industrial efficiency, the significance of a Braszed Heat Exchanger cannot be overstated. These advanced heat transfer devices are becoming increasingly essential across various sectors, providing unparalleled performance and reliability that directly impacts operational productivity. As industries continue to push the boundaries of energy efficiency and thermal management, understanding the benefits of the best brazed heat exchangers emerges as a crucial factor for success. From enhanced thermal conductivity to reduced maintenance costs, the advantages provided by these robust systems are not just superficial; they fundamentally transform how heat transfer processes are executed. In this article, we will delve into seven compelling reasons why investing in high-quality brazed heat exchangers can streamline operations, reduce energy consumption, and ultimately lead to significant cost savings for your industrial applications.

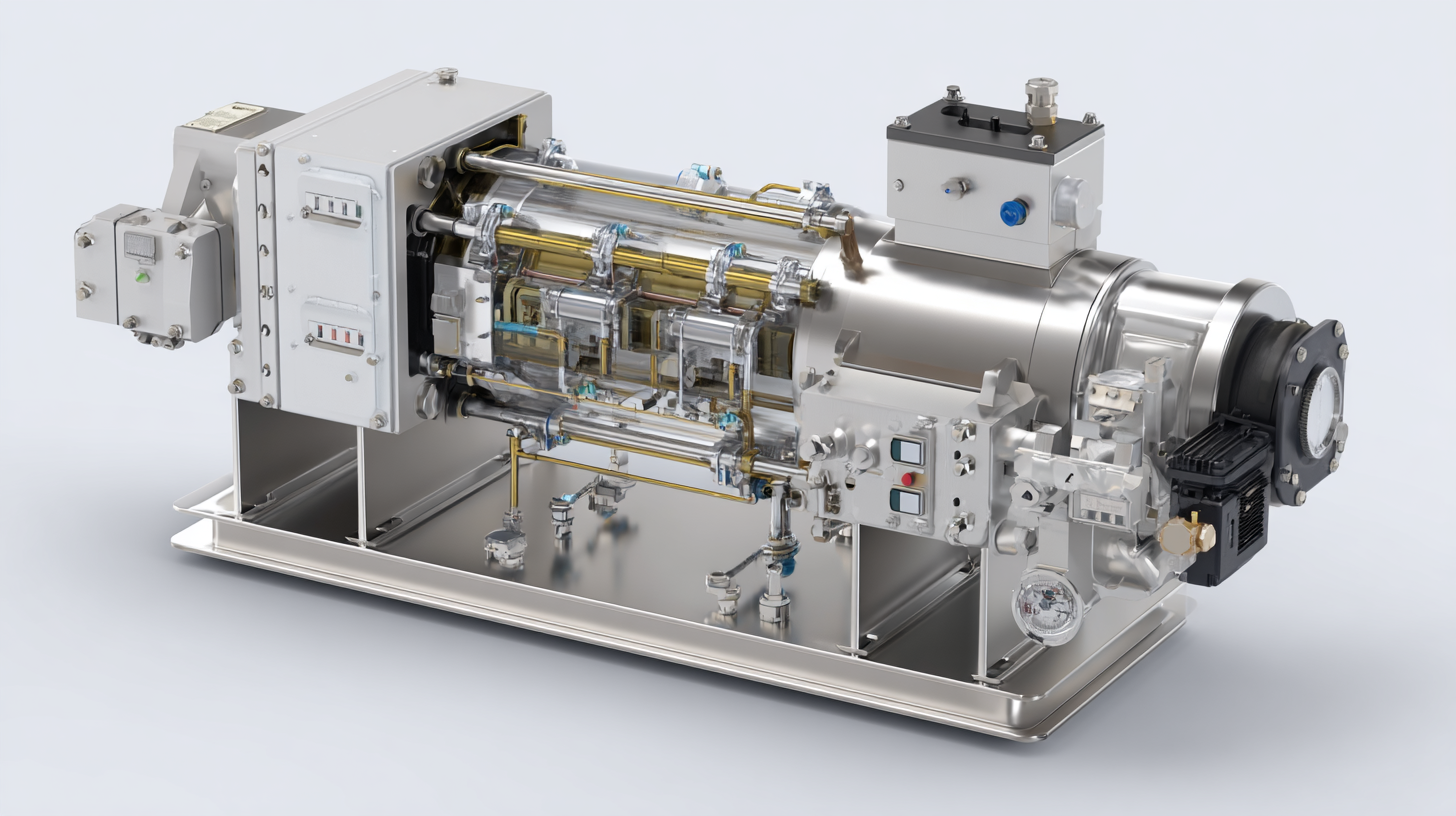

Brazed heat exchangers have become indispensable in various industrial applications due to their superior efficiency and effectiveness in thermal management. Their design enables them to withstand high pressures and temperatures, making them ideal for use in chemical processing, food processing, and power generation industries. This capacity not only enhances the overall performance of industrial systems but also reduces energy consumption, a critical factor in today’s sustainability-focused environment.

One key benefit of brazed heat exchangers is their compactness, which allows for significant space savings in manufacturing facilities. This feature facilitates easier installation and maintenance, ultimately leading to reduced downtime. Additionally, the absence of gaskets in brazed designs eliminates potential leaks, further ensuring reliability in critical processes. As industries continue to embrace technological advancements, the demand for efficient heat transfer solutions like brazed heat exchangers is expected to drive market growth, with projections estimating the heat exchanger market to reach $31.52 billion by 2032.

Traditional heat exchangers often face a myriad of challenges that can impede industrial efficiency. One prevalent issue is fouling, which can significantly reduce thermal performance and increase maintenance costs. According to a report by the International Energy Agency (IEA), fouling can lead to energy losses of up to 30%, underscoring the critical need for effective heat transfer solutions. Additionally, the degradation of heat transfer surfaces over time can result in diminished operational reliability, further complicating industrial processes.

Another challenge is the weight and footprint of traditional units. Conventional heat exchangers can occupy substantial space and are often cumbersome, making them less suitable for modern industrial settings that prioritize compactness and efficiency. A study published in the Journal of Industrial Technology noted that investing in advanced brazed heat exchangers can reduce system size by up to 50%, thus enabling better space utilization without sacrificing performance. This compact design also contributes to easier installation and lower transportation costs, making it a strategic advantage in today's competitive industrial landscape.

Brazed heat exchangers play a pivotal role in enhancing energy efficiency across various industrial applications. With the global heat exchanger market projected to grow significantly, the emphasis on energy-efficient technologies is more critical than ever. These heat exchangers excel in transferring heat with minimal energy losses, allowing industries to reduce operational costs and streamline energy use. Their compact design and robust construction lead to improved thermal performance, making them ideal for demanding environments.

In the context of net-zero energy buildings, efficient heating, ventilation, and air-conditioning (HVAC) systems are essential. Brazed heat exchangers contribute to these systems by maximizing heat transfer and minimizing energy consumption, supporting sustainable practices. As energy efficiency regulations tighten, the ability of brazed heat exchangers to reduce energy demand while maintaining system performance will become increasingly valuable, driving their adoption across both commercial and industrial sectors. Their advantages not only foster operational efficiency but also align with global sustainability goals, marking them as a key technology in the pursuit of energy conservation.

When selecting a heat exchanger for your industrial needs, there are several key factors that must be taken into account to ensure optimal efficiency and performance. First and foremost, material compatibility is critical. Different applications may involve corrosive substances or extreme temperatures, necessitating the use of specific materials that can withstand such conditions without degradation. Employing a heat exchanger made from suitable materials can significantly extend its lifespan and boost overall reliability.

Another crucial aspect is the design and configuration of the heat exchanger. Brazed heat exchangers, known for their compactness and high thermal efficiency, can provide substantial space savings in various industrial settings. Additionally, understanding the flow arrangement, whether counterflow or parallel flow, can influence heat transfer efficiency. Finally, maintenance needs should also be considered; selecting a heat exchanger that facilitates easy cleaning and inspection will contribute to greater long-term efficiency and reduce downtime in operations.

With the global heat exchanger market projected to expand at a compound annual growth rate of 8.26% from 2024 to 2032, investing time in these considerations is more essential than ever to stay competitive and capitalize on industry growth.

Brazed heat exchangers have become indispensable across various industrial sectors, especially when it comes to maximizing efficiency and performance. A recent report by Research and Markets highlights that the global heat exchanger market is projected to reach $22.56 billion by 2027, with brazed solutions playing a vital role in this growth.

One compelling case study involves a leading chemical processing facility that implemented brazed heat exchangers to optimized heat transfer processes, resulting in a remarkable 20% reduction in energy consumption. This significant efficiency boost not only improved their bottom line but also contributed to their sustainability goals.

Another success story comes from a major HVAC manufacturer that transitioned to brazed plate heat exchangers, allowing for more compact designs while enhancing thermal performance. By leveraging advanced brazing technology, this manufacturer experienced a 15% decrease in material costs and a 30% increase in overall system efficiency. As these real-world examples demonstrate, investing in the best brazed heat exchangers can lead to substantial operational improvements, proving their essential role in driving industrial efficiency forward.