Leave Your Message

In the quest for energy efficiency, the role of Plate Exchangers cannot be overstated. According to a recent report by the Heat Exchange Society, effective heat transfer systems can save up to 30% in energy costs. Industry experts, like Dr. Emily Carter, emphasize the importance of such technology. She once stated, "The right Plate Exchanger design significantly enhances system performance." This highlights the need for innovative solutions in thermal management.

The demand for Plate Exchangers continues to grow. Industries are increasingly looking for ways to optimize their processes and reduce operational costs. A well-designed Plate Exchanger offers numerous advantages, including compactness and improved heat recovery rates. However, selecting the ideal design can be challenging. Often, companies overlook specific applications, leading to suboptimal performance.

Consideration must also be given to maintenance and operational challenges. While Plate Exchangers provide high efficiency, they require regular upkeep to sustain their benefits. Failure to maintain these systems can result in reduced effectiveness. Therefore, understanding both the advantages and potential drawbacks is essential for maximizing heat transfer efficiency.

Plate exchangers are vital for efficient heat transfer in various industries. Their high thermal efficiency allows for effective energy usage, reducing operational costs. With a compact design, these exchangers can fit in small spaces, making them ideal for confined setups. Many facilities benefit from lower energy consumption and improved sustainability by utilizing plate exchangers.

To maximize their thermal efficiency, consider the fluid type and flow rates. The choice directly impacts heat transfer rates. Maintain a balance; too low a flow rate may lead to inadequate heat exchange. Regular maintenance is also crucial. Check for fouling and leaks, as these can diminish efficiency over time.

When selecting a plate exchanger, evaluate its surface area and configuration. A larger surface area typically enhances heat transfer. However, don't neglect the potential challenges of cleaning and maintenance. Striking the right balance between efficiency and practicality requires careful thought.

Many operators overlook the importance of regular inspections. Neglect can lead to operational inefficiencies. Ensure team members are aware of maintenance schedules. This can prevent unforeseen downtime and costly repairs. Optimal heat transfer can only be achieved through diligence and attention to detail.

Plate heat exchangers are increasingly recognized for their efficiency. They enable effective heat transfer between two fluids, minimizing energy waste. This design enhances heat recovery, allowing systems to reuse energy. As a result, industries can significantly lower operational costs.

The financial benefits of energy recovery are tangible. By reclaiming heat that would otherwise be lost, facilities cut down on fuel costs. Many systems boast a return on investment within a few years. Yet, not all operations manage to achieve this. Some may face challenges in integrating new technology effectively.

Monitoring system performance is crucial. Regular maintenance can prevent costly downtime. It’s essential to assess heat exchanger efficiency periodically. Innovations in design continue to improve performance, but not all adapt quickly. Exploring options is necessary for everyone looking to maximize savings.

Plate heat exchangers (PHEs) offer a compact design. This design significantly contributes to space optimization in various industrial applications. Research shows that PHEs can save up to 50% more space compared to traditional shell-and-tube heat exchangers. In crowded facilities, every square foot counts. Having a compact unit allows for more efficient use of available space.

The efficiency of heat transfer in plate exchangers is impressive. Their large surface area enhances heat exchange rates, making them ideal for tight spaces. A study revealed that when PHEs are used, energy consumption decreases by about 20% in some applications. However, it's essential to remember that the design may complicate maintenance.

While many facilities see benefits, the compact design does pose challenges. For instance, accessing plates for cleaning can be difficult. This sometimes leads to overlooked maintenance tasks. Therefore, companies need to evaluate their processes regularly. Understanding the balance between space efficiency and maintenance accessibility is crucial for optimal performance.

Plate exchangers offer remarkable scalability and flexibility in various industrial applications. Their design allows for easy integration into existing systems. Different industries, such as food processing and chemical manufacturing, benefit from this versatility. Adjusting the heat exchanger configuration is simple, accommodating changes in production demands.

Implementing plate exchangers requires careful planning. Assessing specific needs is crucial. It is essential to choose the right materials for durability. Remember, incorrect choices can lead to inefficiencies. Regular maintenance should be a priority to ensure optimal performance.

Tip: Conduct regular performance evaluations. This will help identify any inefficiencies in the system.

In addition, plate exchangers can adapt to various flow rates and temperatures. This adaptability minimizes downtime during transitions. However, it's important to ensure proper calibration for precise operations. The initial setup might seem daunting, but the long-term benefits are significant. Flexibility can lead to improved energy savings and reduced costs.

Tip: Always keep a close eye on operating conditions. Small changes can make a big difference in efficiency.

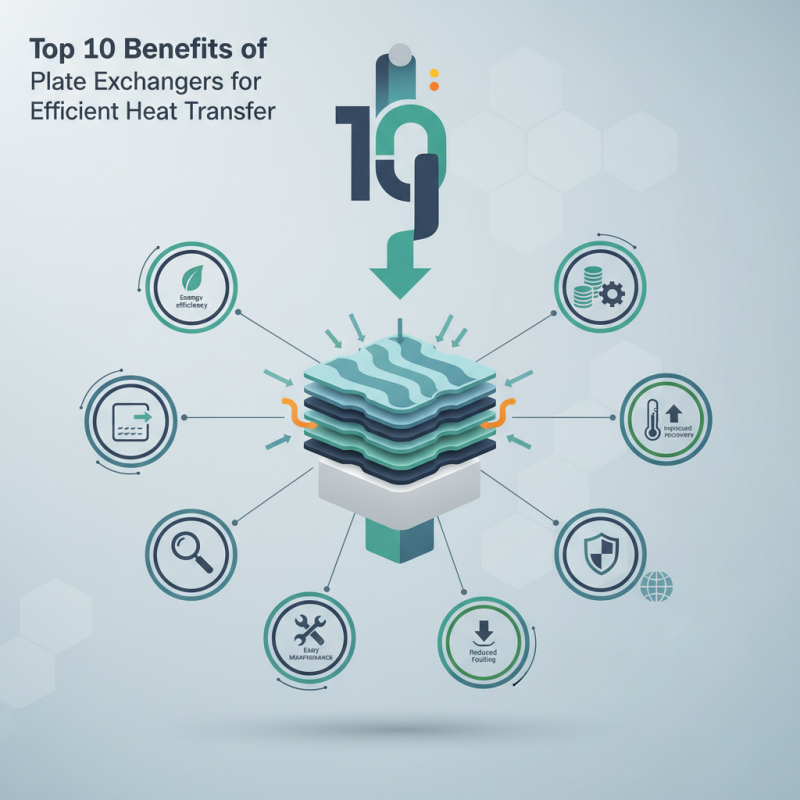

This chart illustrates the top 10 benefits of using plate exchangers for heat transfer, highlighting their various advantages in industrial applications, including enhanced efficiency, scalability, and reduced operational costs.

Plate exchangers are known for their efficient heat transfer capabilities. However, their maintenance and cleaning process plays a crucial role in ensuring longevity. Regular cleaning avoids fouling, which can impede heat transfer efficiency. This is necessary for optimal performance. It keeps the system running smoothly and reduces downtime.

Cleaning a plate exchanger doesn't have to be complex. Many designs allow for easy access to plates. Operators can quickly disassemble units for thorough cleaning. Using the right cleaning agents ensures surfaces are not damaged. Yet, not all operators follow best practices. Some overlook scheduled maintenance, leading to costly repairs.

Routine inspections can catch issues early. During these inspections, replace worn-out gaskets and check for corrosion. Ignoring these tasks can lead to breakdowns. A proactive approach to maintenance is essential for longevity. Moreover, operator training is vital. Staff must understand the importance of frequent cleaning and upkeep. Without this knowledge, efficiency can diminish over time.