Leave Your Message

In today's rapidly evolving energy landscape, the pursuit of efficient energy recovery solutions has never been more critical. PHE heat exchangers, or Plate Heat Exchangers, have emerged as a vital component in optimizing energy transfer processes across various industries. According to Dr. Mark Thompson, a leading expert in thermal engineering, "The adoption of PHE heat exchangers can significantly enhance energy recovery and system efficiency, paving the way for more sustainable industrial practices." His insights highlight the importance of these systems in reducing energy waste and improving overall operational performance.

The versatility of PHE heat exchangers allows them to be employed in diverse applications, from chemical processing to HVAC systems, making them an integral part of modern energy management strategies. By facilitating effective heat transfer between two fluids, PHE heat exchangers contribute to not only energy savings but also reduced emissions, aligning with global efforts towards sustainability. As industries increasingly recognize the benefits of incorporating PHE technology, understanding the top advantages of these innovative systems becomes essential for engineers and decision-makers alike.

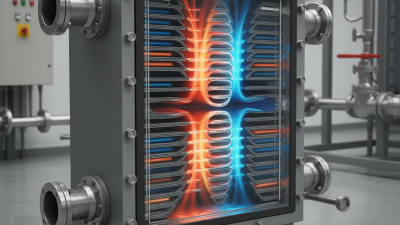

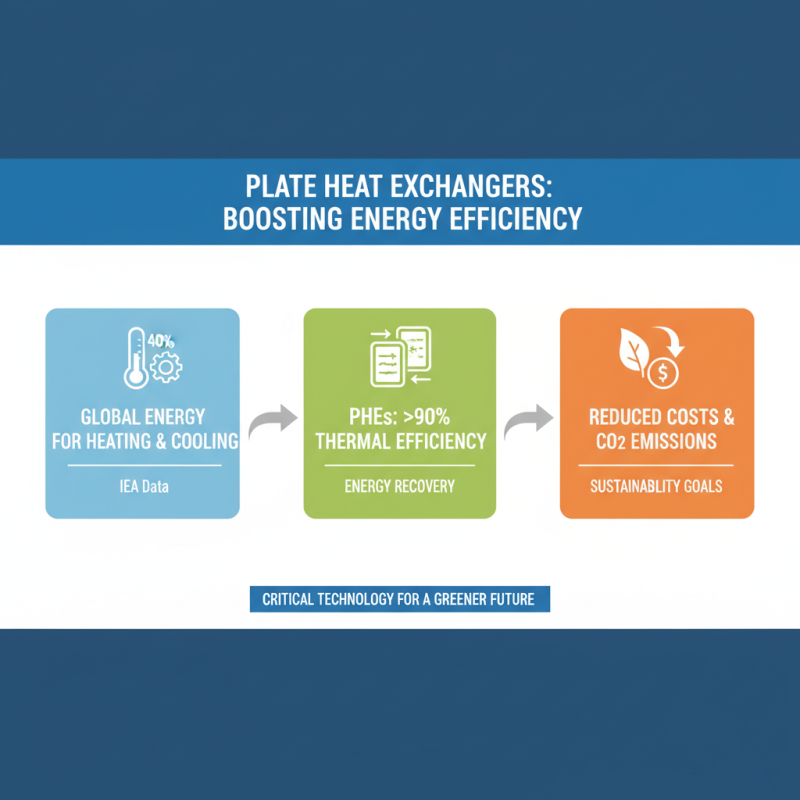

Plate Heat Exchangers (PHE) have emerged as a critical technology for enhancing energy efficiency across various industrial applications. According to the International Energy Agency, nearly 40% of the world's energy consumption is linked to heating and cooling processes. PHEs offer significant advantages in these areas, particularly in terms of energy recovery, where they can achieve thermal efficiencies exceeding 90%. This capability leads to reduced energy costs and lower carbon emissions, aligning with sustainability goals for many organizations.

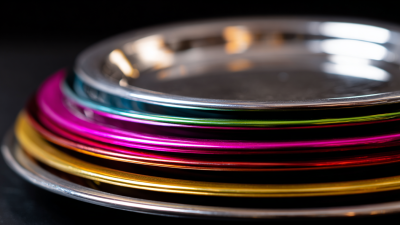

In addition to high thermal efficiency, PHEs are known for their compact design, which allows for better space utilization in facilities. A study published by the U.S. Department of Energy highlights that implementing PHEs can lead to a 20-50% reduction in the heat transfer area compared to traditional heat exchangers. This not only yields economic benefits by minimizing installation space but also enables easier maintenance and increased operational flexibility. Moreover, their ability to handle high-temperature and high-pressure applications makes PHEs suitable for diverse industries, from food processing to petrochemicals, thereby broadening their impact on energy efficiency improvements.

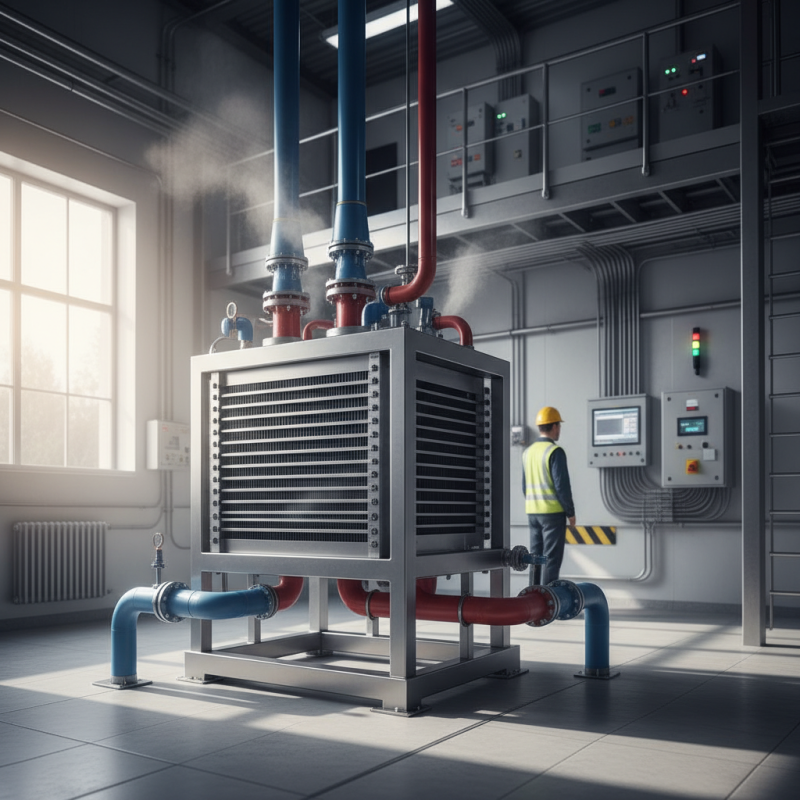

Plate heat exchangers (PHE) have emerged as a crucial technology in the quest for efficient energy recovery, particularly in reducing operational costs across various industries. According to a report from the International Energy Agency (IEA), heat recovery systems can improve energy efficiency by up to 30% in manufacturing processes. PHEs play a pivotal role in this by maximizing the transfer of thermal energy, leading to significant reductions in energy consumption and lower utility bills. By efficiently transferring heat between liquids, PHEs not only enhance energy recovery but also minimize waste heat emissions, contributing to a greener and more sustainable operation.

Implementing PHEs can lead to substantial operational cost savings. A study from the Department of Energy (DOE) highlights that organizations utilizing heat exchangers have reported reduced heating and cooling costs by as much as 20%. This reduction stems from the ability of PHEs to operate effectively under variable temperatures and pressures, allowing industries to optimize their heating and cooling cycles. Moreover, the compact design of PHEs means they require less space and fewer materials, resulting in lower installation and maintenance costs.

**Tips:** When considering the integration of PHEs into your processes, ensure to conduct a thorough analysis of your current energy consumption patterns. Regular maintenance of your PHE system can also prevent efficiency loss and extend the lifespan of the equipment. Additionally, evaluating the thermal requirements and selecting the appropriate capacity for your heat exchanger will significantly enhance energy savings.

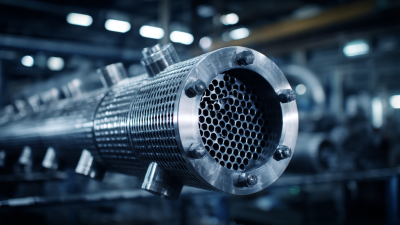

Plate Heat Exchangers (PHEs) have gained significant attention for their superior performance in energy recovery compared to traditional heat exchangers. One of the main advantages of PHEs is their compact design, which allows for a higher heat transfer efficiency in a smaller footprint. This results in a substantial reduction in space requirements, making them ideal for applications where space is at a premium. Additionally, the higher coefficients of heat transfer associated with PHEs lead to improved energy recovery, translating into lower operating costs and a decreased carbon footprint.

In contrast, traditional heat exchangers, such as shell-and-tube models, often suffer from limitations related to size and maintenance. Their larger volume not only demands more installation space but also can lead to reduced efficiency during energy recovery processes. Moreover, the cleaning and maintenance of these older models can be cumbersome due to their complex structure, making them less favorable for continuous operation. PHEs, with their easily accessible plates, enable quicker maintenance, which minimizes downtime and enhances overall system reliability. Ultimately, the comparative benefits of PHEs over traditional models underscore the growing trend towards more efficient and sustainable energy recovery solutions.

| Benefit | PHE Heat Exchangers | Traditional Models |

|---|---|---|

| Higher Thermal Efficiency | Yes | No |

| Compact Design | Yes | No |

| Easy Maintenance | Yes | Limited Access |

| Flexible Configuration | Yes | No |

| Reduced Energy Costs | Yes | Increased Costs |

| Lower Pressure Drop | Yes | Higher Pressure Drop |

| Versatile Applications | Wide Range | Limited Range |

| Enhanced Heat Transfer | Superior | Average |

| Corrosion Resistance | Strong Resistance | Susceptible |

| Sustainability | Yes | Less Eco-Friendly |

PHE heat exchangers, or plate heat exchangers, are gaining traction across various industries for their ability to optimize energy recovery efficiently. Industries such as food and beverage, chemical processing, and HVAC are increasingly implementing PHE technology to enhance their thermal management processes. In the food sector, for instance, these heat exchangers enable the recovery of waste heat from production processes, which can then be redirected for use in pasteurization or heating. This not only minimizes energy consumption but also reduces operational costs.

Tips: When selecting a PHE heat exchanger for your operations, consider the temperature and pressure requirements of your application to ensure optimal performance. Additionally, regular maintenance is crucial for sustaining efficiency—cleaning the plates periodically can help prevent fouling and maintain effective heat transfer.

In the chemical industry, PHEs facilitate more sustainable practices by enabling the recovery of heat from exothermic reactions. This recovered energy can be reused in other parts of the process, leading to substantial energy savings and a lower carbon footprint. The HVAC sector benefits similarly, with PHEs improving the efficiency of cooling systems by recovering heat that can be repurposed for heating water or indoor spaces.

Tips: Integrating smart monitoring systems can help track the performance of PHE heat exchangers, allowing for adjustments that maximize energy recovery and efficiency. Investing in training for staff on how to operate and maintain these systems can further enhance their effectiveness, ensuring that organizations reap the full benefits of PHE technology.

PHE (Plate Heat Exchanger) technology is revolutionizing energy recovery rates across various industries. By utilizing a series of plates to transfer heat between two fluids, PHEs significantly enhance the efficiency of energy recovery systems. Statistical analyses have shown that facilities employing PHE technology can achieve energy recovery rates exceeding 90%. This is a remarkable improvement when compared to traditional heat exchanger systems, which often struggle to surpass the 70% mark. The increased contact surface area provided by PHEs allows for more effective heat transfer, ultimately leading to reduced energy costs and a smaller carbon footprint.

When considering the integration of PHE technology, it is essential to assess the specific heat transfer requirements of your application. One tip is to conduct a thorough energy audit to identify areas where heat recovery is optimal. Additionally, regular maintenance of PHE systems ensures their longevity and efficiency. Another important consideration is the potential for pre-cooling or pre-heating processes, which can further enhance overall system performance and contribute to significant savings. By utilizing PHE technology effectively, industries can not only improve energy efficiency but also drive sustainability initiatives forward.