Leave Your Message

The significance of thermal management in various industrial applications cannot be overstated, particularly in processes requiring precise temperature control. One of the most effective solutions in this domain is the Plate Heat Exchanger (PHE), known for its compact design and efficient heat transfer capabilities. According to a recent report by the Global Heat Exchanger Market, the average heat exchange efficiency of PHE can reach up to 90%, significantly higher than traditional shell and tube exchangers. This remarkable efficiency not only helps in reducing energy consumption but also minimizes operational costs, making Heat Exchanger PHE a vital component in enhancing the overall performance of energy systems.

In addition to efficiency, Heat Exchanger PHEs offer substantial benefits in terms of maintenance and longevity. A study conducted by the Heat Transfer Society highlighted that PHEs require less maintenance than conventional systems, thanks to their modular design, which allows for easy access to individual plates for cleaning or replacement. Furthermore, the robust materials used in their construction contribute to their durability, further validating the investment in Heat Exchanger PHE systems for various industries, including food processing, HVAC, and chemical manufacturing. As businesses strive for sustainability and energy savings, understanding the top benefits of Heat Exchanger PHE becomes essential for making informed choices in thermal management solutions.

Heat exchangers, particularly Plate Heat Exchangers (PHE), have become essential in a variety of industries, offering efficiency and versatility in thermal management. One compelling benefit of PHEs is their ability to recover waste heat, which can lead to significant energy savings. According to a report from the Department of Energy, optimizing waste heat recovery can improve industrial energy efficiency by up to 30%. This reduction not only cuts operational costs but also minimizes the carbon footprint of manufacturing processes, aligning with global sustainability goals.

Another key advantage of PHEs is their compact design, which allows for a high heat transfer area within a limited space. This is particularly beneficial in applications where layout constraints demand efficient thermal management solutions. Additionally, PHEs operate at lower maintenance costs due to their streamlined design, which typically results in less fouling compared to traditional heat exchangers. As highlighted by industry studies, maintaining efficiency within these systems can enhance overall system performance by up to 20%.

**Tip:** To maximize the efficiency of your heat exchanger system, regularly inspect and clean your PHE to prevent fouling. Implementing a preventive maintenance schedule can significantly enhance thermal performance and prolong equipment lifespan.

**Tip:** When selecting a heat exchanger, consider factors such as fluid properties, operating temperatures, and pressure drops. Tailoring these parameters to your specific application can lead to optimal thermal management and improved energy efficiency.

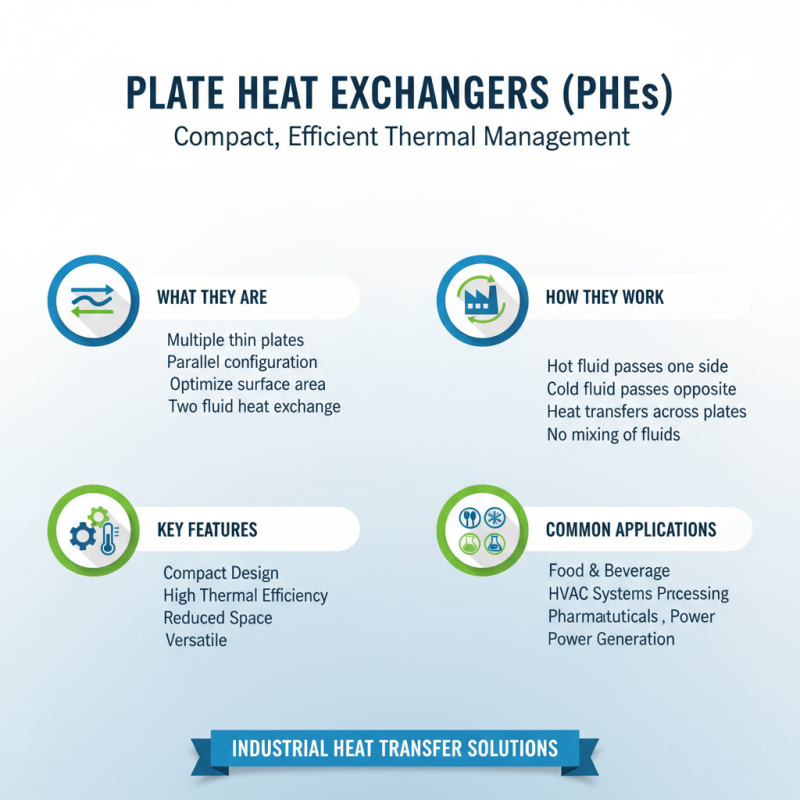

Plate heat exchangers (PHE) are essential components in various industrial applications, adeptly facilitating thermal management through efficient heat transfer. Their design, characterized by multiple thin plates arranged in a parallel configuration, optimizes the surface area for heat exchange between two fluids. This compact design not only reduces space requirements but also enhances thermal efficiency, making PHEs a preferred choice in industries ranging from food and beverage to HVAC systems and chemical processing.

The functionality of plate heat exchangers hinges on the principles of convection and conduction. As hot and cold fluids flow through alternating channels, heat is transferred from the hot fluid to the cold fluid without the two ever mixing. This process is further enhanced by the turbulence created as fluids pass over the corrugated plates, ensuring maximum surface contact and heat transfer. Moreover, the modular nature of PHEs allows for easy maintenance and scalability, accommodating varying thermal loads across different industrial settings. This flexibility ensures they continue to serve critical roles in maintaining optimal operating temperatures and energy efficiency across diverse processes.

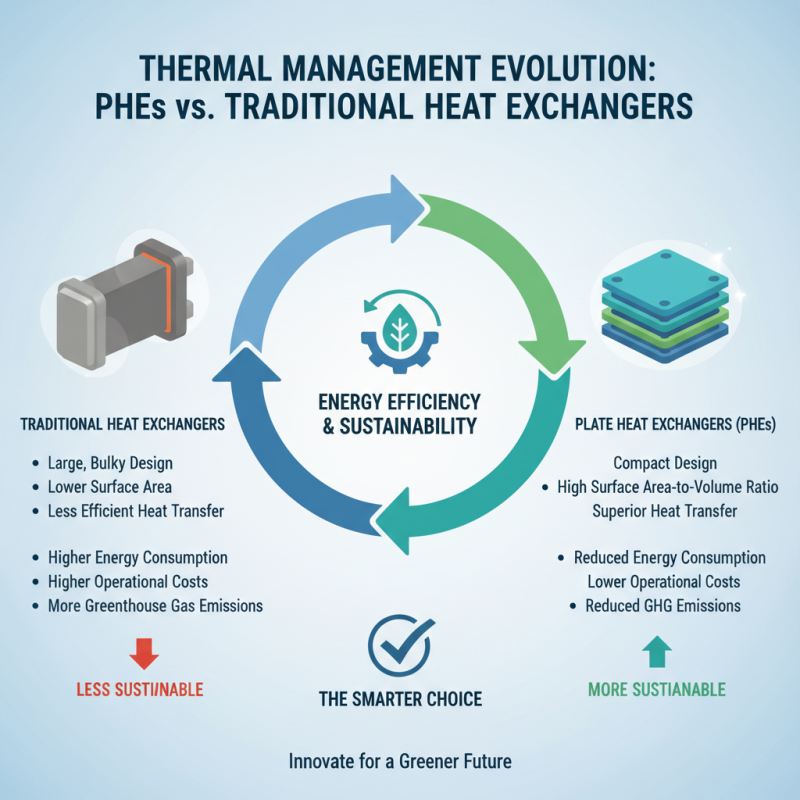

The evolution of thermal management technology has highlighted the importance of energy efficiency metrics, particularly when comparing Plate Heat Exchangers (PHEs) with traditional heat exchangers. PHEs utilize a compact design and a high surface area-to-volume ratio, which allows them to transfer heat more effectively while consuming less energy. This enhanced efficiency translates not only into reduced operational costs but also into lower greenhouse gas emissions, making PHEs a favorable choice in industries aiming for sustainability.

When evaluating the energy efficiency of heat exchangers, consider the overall heat transfer coefficient and the pressure drop across the system. PHEs generally show superior performance in these metrics due to their design, which minimizes flow resistance and maximizes heat transfer. This means that for facilities looking to optimize their energy consumption, switching to PHEs could lead to significant savings and improved performance.

**Tips:** Always conduct a thorough analysis of your specific application needs to ensure that you select the most suitable type of heat exchanger. Regular maintenance and cleaning of PHEs can vastly improve their efficiency and longevity. Additionally, employing advanced monitoring systems can help identify potential inefficiencies early, allowing for timely adjustments and optimizations in thermal management strategies.

The rising demand for energy efficiency in industrial processes has placed a significant emphasis on optimizing thermal management systems.

Plate Heat Exchangers (PHE) have emerged as a leading solution for maintaining effective heat transfer while simultaneously reducing energy consumption. By maximizing the surface area for heat transfer and minimizing fluid hold-up, PHEs facilitate efficient heat recovery and exchange between fluids, enabling operations to run with lower energy input.

One of the most notable benefits of implementing PHE systems is cost savings derived from reduced energy consumption. Traditional heat exchangers often suffer from fouling and limited heat transfer efficiency, leading to increased operational costs as more energy is needed to maintain desired temperatures. In contrast, PHEs maintain higher efficiency levels over time due to their design, which limits fouling and degradation of performance. This sustained efficiency translates to lower energy bills, allowing organizations to redirect these savings towards other operational improvements or innovations.

Moreover, as industries face growing pressure to minimize their environmental impact, the role of energy-efficient systems like PHEs becomes even more crucial. By significantly decreasing energy requirements, businesses not only cut costs but also contribute to a reduced carbon footprint. This dual benefit of financial savings alongside environmental responsibility makes PHEs an attractive option for industries aiming for sustainable growth and optimal thermal management.

Plate Heat Exchangers (PHE) have revolutionized the way thermal management is approached across various industries. One of the standout features of PHE systems is their enhanced thermal performance, particularly evident in the heat transfer coefficients. The unique design of plates creates multiple flows that maximize the surface area for heat exchange, ensuring optimal thermal efficiency. This results in both energy savings and improved process control, making PHE a preferred choice for many applications.

When considering PHE for your systems, it’s important to keep in mind a few tips to enhance their performance. Firstly, ensure that the flow rates of fluids are optimized to achieve the best heat transfer rates. Balancing the flow can often lead to significant improvements in thermal performance. Secondly, regular maintenance of PHE systems is crucial; accumulated fouling can drastically reduce heat transfer efficiency. Periodic cleaning of the plates will help maintain optimal performance and extend the lifespan of the equipment.

Another aspect to consider is the selection of materials used in PHE construction. Different applications may require specific materials to withstand varying temperatures and pressures, thus affecting the overall heat transfer coefficients. Choosing the right material not only optimizes efficiency but also ensures the durability of the system under operational conditions.

| Benefit | Description | Heat Transfer Coefficient (W/m²K) |

|---|---|---|

| High Efficiency | PHEs provide superior heat transfer efficiency compared to other types of exchangers. | 1500 - 5000 |

| Compact Design | The compact design saves space within the facility. | N/A |

| Flexibility | PHEs can be customized and modified easily to meet specific needs. | N/A |

| Corrosion Resistance | Made from various materials to withstand corrosive environments. | N/A |

| Low Maintenance | Easier to clean and service without the need for extensive downtime. | N/A |

| Enhanced Thermal Performance | Higher heat exchange rates result in improved energy efficiency. | 2000 - 8000 |

| Temperature Control | Allows for precise temperature regulation in various processes. | N/A |

| Energy Savings | Reduction in energy costs due to improved heat recovery. | N/A |

| Sustainability | Contributes to lower carbon footprint and energy usage. | N/A |

The article "Top 10 Benefits of Heat Exchanger PHE for Efficient Thermal Management" explores the advantages of Plate Heat Exchangers (PHE) in various industrial applications. It delves into how PHEs function effectively to manage thermal energy, highlighting their superior energy efficiency compared to traditional heat exchangers. The article emphasizes the significant cost savings that result from reduced energy consumption and enhanced thermal performance, thanks to improved heat transfer coefficients in PHE systems.

Furthermore, it discusses the longevity and low maintenance requirements of Plate Heat Exchangers, illustrating their reliability in continuous operations. Overall, the insights provided underscore the critical role of Heat Exchanger PHEs in optimizing energy use and ensuring efficient thermal management across multiple sectors.