Leave Your Message

In the quest for optimizing thermal efficiency and maximizing energy savings in various industrial applications, the Brazed Plate Heat Exchanger has emerged as a formidable option. This advanced heat exchanger design utilizes a series of thin metal plates that are brazed together to facilitate efficient heat transfer between two fluids. With a compact structure and a remarkable ability to handle high pressure and temperature, Brazed Plate Heat Exchangers are reshaping the landscape of thermal management systems across multiple sectors.

The benefits of employing Brazed Plate Heat Exchangers are manifold, ranging from enhanced thermal performance and reduced footprint to superior durability and low maintenance requirements. As industries increasingly demand sustainable solutions that minimize energy consumption and operational costs, understanding the top advantages of this innovative technology becomes essential. In the following sections, we will delve into the key benefits that make Brazed Plate Heat Exchangers a preferred choice for engineers and facility managers looking to upgrade or implement efficient heat transfer systems.

Brazed plate heat exchangers (BPHE) are advanced thermal transfer devices composed of multiple thin plates. These plates are tightly packed and bonded together using brazing techniques, creating a compact design that maximizes heat transfer efficiency. BPHEs are renowned for their ability to handle a variety of fluids while providing superior thermal conductivity. Their compact size allows them to fit into tight spaces, making them an ideal choice for applications where limited space is a concern.

The construction of brazed plate heat exchangers promotes enhanced heat transfer due to the large surface area created by the plates. This increased surface area facilitates more effective thermal exchange between the fluids. Furthermore, the rigid structure of BPHEs ensures durability and reliability under high-pressure and high-temperature conditions. Their versatility enables them to be used in different industries, including HVAC, refrigeration, and process engineering, providing a vital solution for energy-efficient thermal management.

| Benefit | Description |

|---|---|

| Compact Design | Brazed plate heat exchangers have a smaller footprint compared to traditional heat exchangers, making them suitable for space-constrained applications. |

| High Efficiency | These heat exchangers provide significant thermal efficiency due to enhanced heat transfer surfaces. |

| Durability | Made from stainless steel, brazed plate heat exchangers are resistant to corrosion and high-pressure conditions. |

| Wide Range of Applications | They are versatile and can be used in various industries including HVAC, refrigeration, and oil and gas. |

| Easy Installation | Their compact size allows for easier setup and installation in new and existing systems. |

| Low Maintenance | Brazed plates are designed to minimize fouling, reducing the frequency and cost of maintenance. |

| Energy Savings | Improved efficiency leads to lower energy consumption and operational costs over time. |

| Safety | They are designed to handle high pressures safely, minimizing risk in critical operations. |

| Customized Solutions | Manufacturers can tailor Brazed plate heat exchangers for specific requirements and fluids. |

| Environmental Benefits | Enhanced heat recovery means less waste and better sustainability practices. |

Brazed plate heat exchangers (BPHEs) have emerged as a highly efficient solution for thermal management across various industries. Their compact design allows for a significant heat transfer area within a small footprint, which is particularly advantageous in applications like refrigeration and heating systems. The unique brazing process enhances the structural integrity of the plates, ensuring durability and reliability even under extreme temperature and pressure conditions.

One of the key advantages of BPHEs is their exceptional thermal efficiency. The plates are stacked in a way that maximizes surface area contact, promoting optimal heat exchange between the fluids. This efficiency not only leads to reduced energy consumption but also minimizes operational costs. Additionally, the absence of gaskets in brazed plates eliminates the risk of leakage and contamination, making them an ideal choice for demanding applications where hygiene is critical, such as in food and pharmaceutical industries. The versatility in construction allows for customization in flow patterns and plate configurations, further enhancing their performance in diverse heat transfer scenarios.

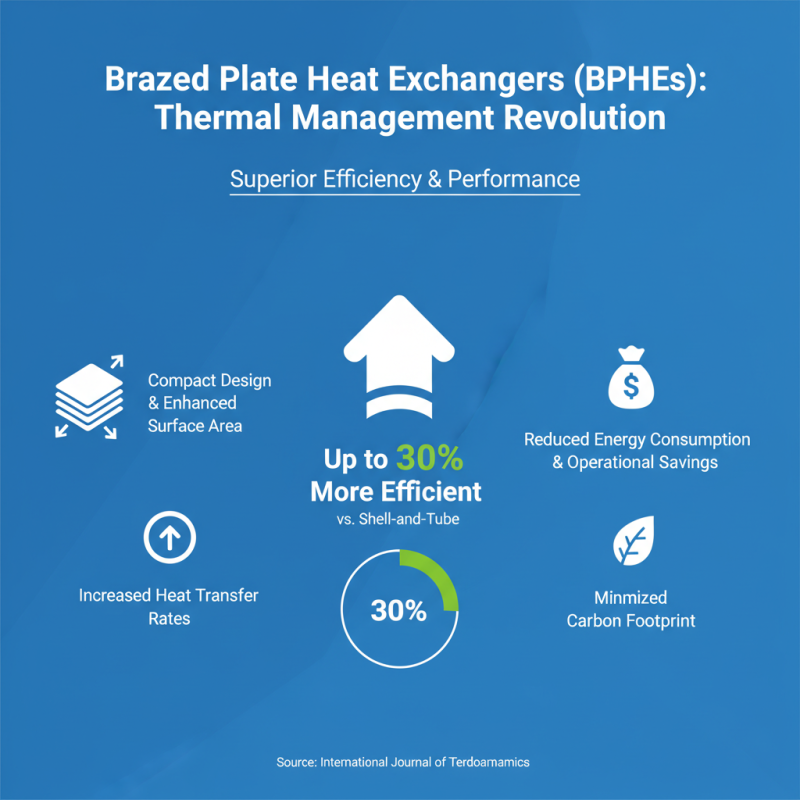

Brazed plate heat exchangers (BPHEs) are revolutionizing the landscape of thermal management in various industries due to their superior efficiency and performance. With their compact design and enhanced surface area, BPHEs allow for increased heat transfer rates, which can significantly reduce energy consumption. According to a report from the International Journal of Thermodynamics, BPHEs can improve heat exchange efficiency by up to 30% compared to traditional shell-and-tube heat exchangers. This not only leads to operational cost savings but also minimizes the carbon footprint of industrial operations.

Furthermore, the durability and reliability of brazed plate heat exchangers contribute to their performance advantages. The process of brazing creates a solid bond with high resistance to thermal cycling and mechanical stresses. Research published in the Journal of Mechanical Engineering shows that BPHEs have a longer lifespan, with reduced maintenance requirements, leading to further operational efficiencies. By maintaining high performance over time, industries can achieve consistent output and quality while reducing downtime attributed to equipment failures. These benefits make brazed plate heat exchangers an attractive choice for many applications, ranging from refrigeration to power generation.

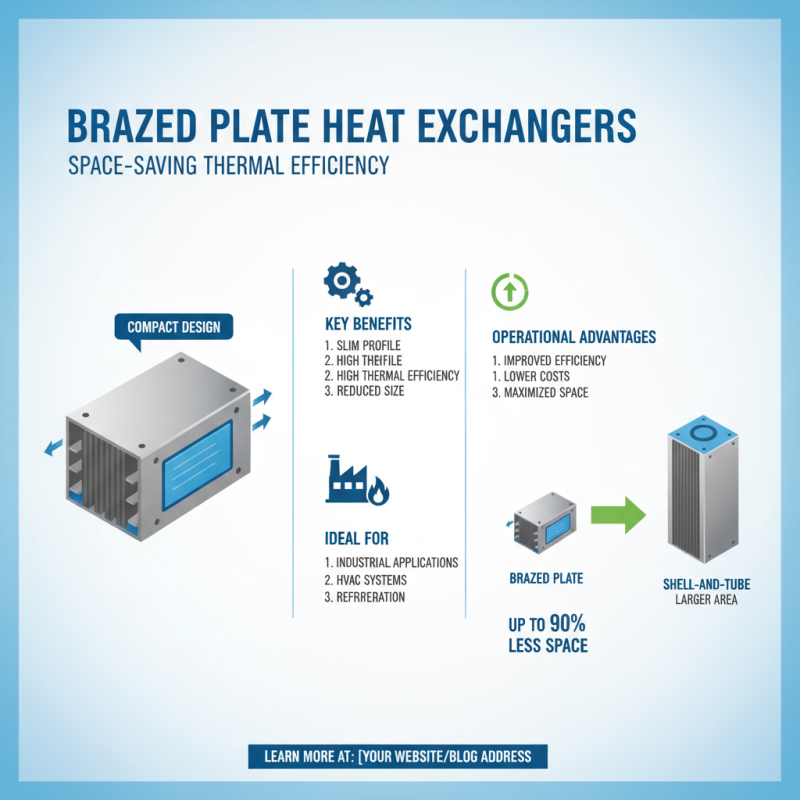

Brazed plate heat exchangers are notable for their compact design, making them an excellent choice for environments where space is at a premium. Their slim profile allows for high thermal efficiency while occupying significantly less area compared to traditional shell-and-tube heat exchangers. This is particularly beneficial in industrial applications, HVAC systems, and refrigeration setups, where maximizing usable space can lead to improved operational efficiency and reduced construction costs.

Additionally, the space-saving benefits of brazed plate heat exchangers extend to their installation versatility. Their lightweight construction means they can be fitted into tight spaces with minimal structural modifications. This flexibility is ideal for retrofitting existing systems or designing new installations in compact areas. Moreover, the enhanced efficiency of these heat exchangers allows for more effective heat transfer in a smaller unit, significantly contributing to energy savings in the long run. This combination of compactness and efficiency positions brazed plate heat exchangers as a smart investment for various applications.

Brazed plate heat exchangers (BPHEs) have become increasingly popular in various industries due to their exceptional cost-effectiveness and durability. According to a report by the International Energy Agency (IEA), using BPHEs can lead to energy efficiency improvements of up to 30% compared to traditional heat exchangers. Their compact design not only translates to lower installation costs but also reduces the amount of space required for heat transfer applications. For industries dealing with heat recovery and refrigeration, these devices can offer a significantly lower total cost of ownership over time, primarily due to their high thermal efficiency and reduced maintenance requirements.

Durability is another critical advantage of brazed plate heat exchangers. Constructed from corrosion-resistant materials and designed to withstand high-pressure scenarios, BPHEs can operate effectively for years without significant degradation. A study published in the Journal of Thermal Engineering indicated that BPHEs can maintain up to 90% of their thermal performance even after extensive cycles of thermal stress, which is much higher than that of traditional shell-and-tube heat exchangers. This resilience not only enhances their lifespan but also diminishes the likelihood of operational disruptions. The integration of these heat exchangers not only leads to cost savings but also provides a reliable solution for industries committed to sustainability and efficient energy use.