Leave Your Message

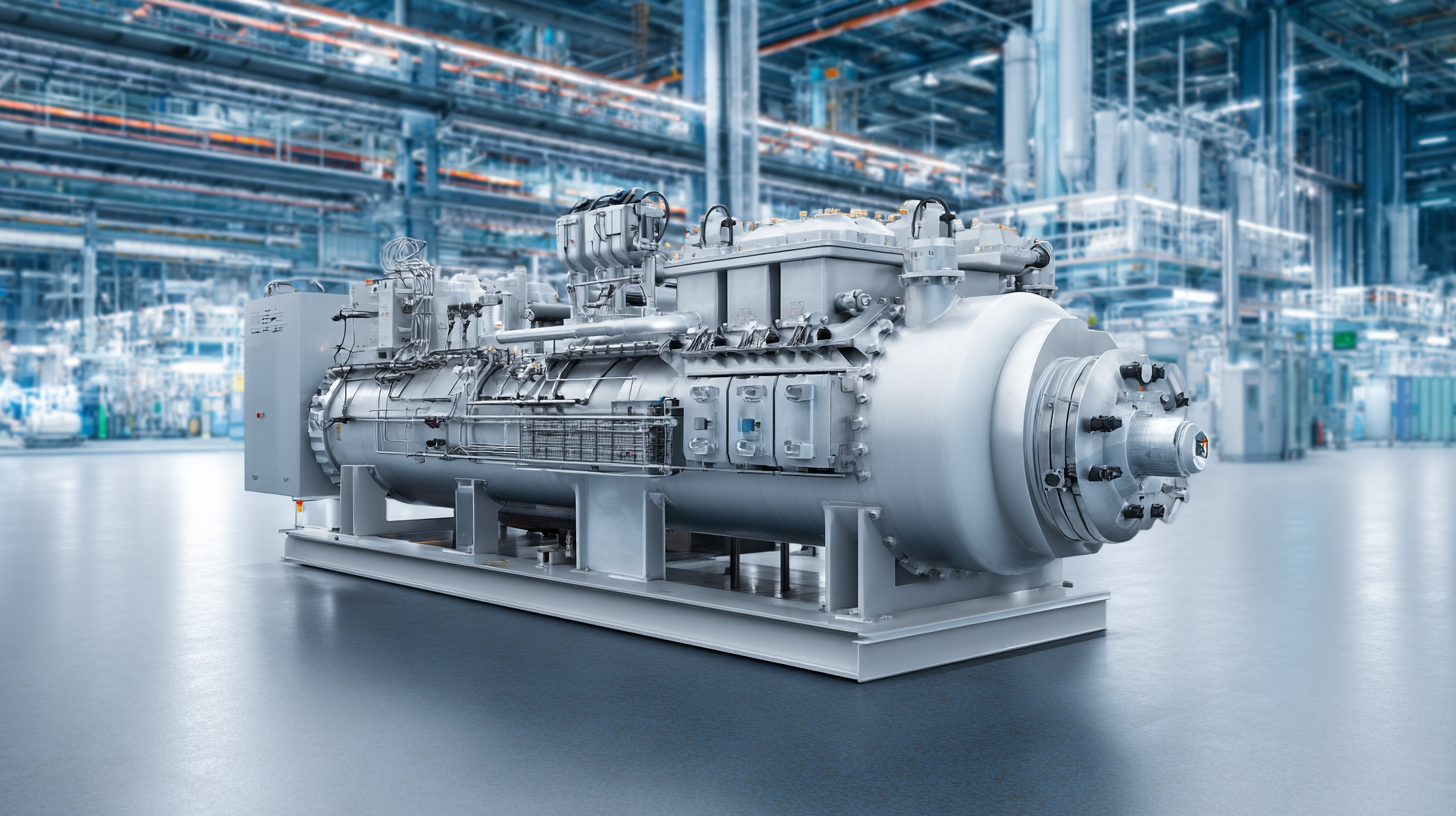

In modern industrial applications, efficiency and sustainability have become paramount, driving the need for advanced technologies that enhance operational performance. One such innovation is the Bpx Heat Exchanger, an essential component designed to optimize heat transfer processes in various sectors. By harnessing the capabilities of the Bpx Heat Exchanger, industries can achieve significant energy savings, reduce waste, and improve overall system reliability.

This article aims to explore the numerous benefits of employing Bpx Heat Exchangers in contemporary settings, highlighting their versatility and effectiveness across different applications. We will delve into how these systems function, their advantages over traditional heat exchangers, and real-world case studies that illustrate their impact. Understanding the role of Bpx Heat Exchangers is crucial for any organization looking to enhance efficiency and sustainability in today's competitive industrial landscape.

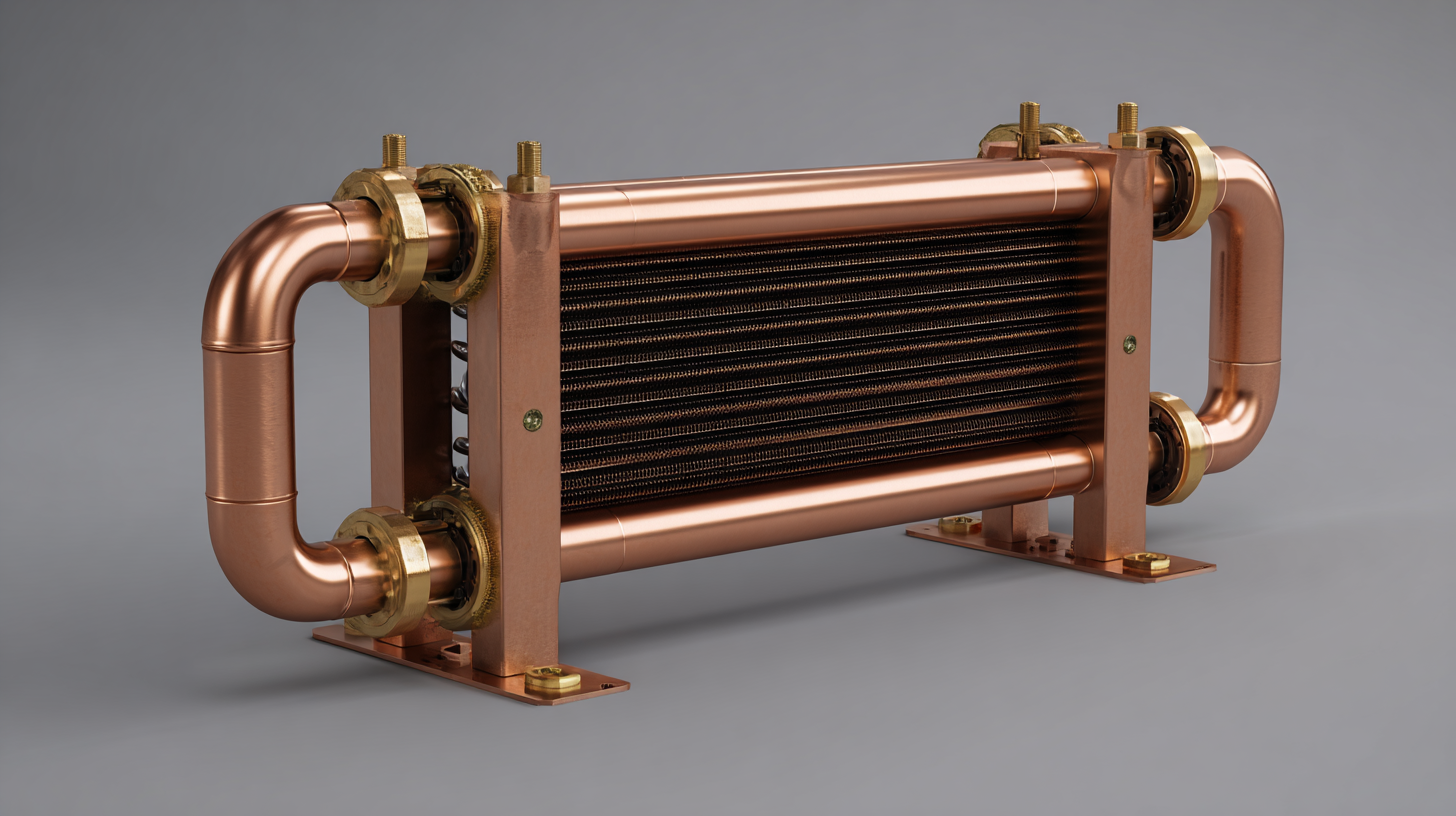

Bpx heat exchangers are engineered with several key design principles that optimize their efficiency in industrial settings. One fundamental aspect is the choice of materials, which must withstand high temperatures and corrosive environments. Typically, materials such as stainless steel or high-nickel alloys are used to ensure durability and longevity. Furthermore, the design must facilitate effective heat transfer while minimizing pressure drop, which is critical for maintaining energy efficiency. This is often achieved through intricate designs, such as the use of multi-tube configurations or finned surfaces that enhance the contact area between the fluids.

Another crucial design principle is the flow arrangement within the heat exchanger. Common configurations include counterflow, parallel flow, and crossflow, each offering distinct advantages depending on the application. Counterflow arrangements, for instance, provide the highest thermal efficiency by allowing the hot and cold fluids to flow in opposite directions, maximizing the temperature gradient. Additionally, optimizing the flow rates and ensuring appropriate fouling management strategies are essential for maintaining performance over time. By adhering to these design principles, Bpx heat exchangers not only improve energy efficiency but also contribute to cost savings and sustainability in modern industrial applications.

Bpx heat exchangers have emerged as critical components across various industries, thanks to their superior thermal efficiency and adaptability. In chemical processing, for example, a recent report by the International Energy Agency highlights that Bpx heat exchangers can enhance heat recovery by up to 25%, significantly reducing energy consumption and operational costs. This efficiency is particularly valuable in processes such as distillation and crystallization, where maintaining specific temperature profiles is crucial.

In the power generation sector, Bpx heat exchangers also play a vital role in improving the overall efficiency of thermal power plants. According to a study published by the International Journal of Heat and Mass Transfer, implementing Bpx technology can lead to efficiency improvements of 5-10% in boilers and condensers. Moreover, the versatility of these heat exchangers allows for their use in renewable energy applications, such as geothermal and solar thermal systems, making them instrumental in the transition towards sustainable energy solutions.

Furthermore, the food and beverage industry benefits from Bpx heat exchangers through enhanced hygiene and operational efficiency, with studies indicating that their use can reduce thermal losses by up to 20%. As industries face increasing pressure to optimize energy use and minimize environmental impact, Bpx heat exchangers stand out as a solution that addresses these challenges effectively across diverse applications.

The BPX heat exchanger stands out as a crucial component in enhancing energy efficiency and driving down operational costs in various industrial applications. Studies indicate that adopting advanced heat exchanger technologies can lead to energy savings of up to 40% in some cases, significantly reducing the carbon footprint of manufacturing processes. For instance, according to a report by the International Energy Agency (IEA), optimizing heat recovery systems can result in annual savings amounting to millions for large scale operations, thereby making BPX heat exchangers a smart investment for industries aiming to lower their energy expenses.

One of the primary advantages of BPX heat exchangers is their ability to operate under high pressures and temperatures, enabling better heat transfer rates and enhanced system reliability. This capability not only improves efficiency but also prolongs the lifespan of equipment, further contributing to cost savings. Additionally, their modular design allows for easier maintenance and upgrades, meaning businesses can adapt quickly to changing energy needs without incurring significant downtimes.

One of the primary advantages of BPX heat exchangers is their ability to operate under high pressures and temperatures, enabling better heat transfer rates and enhanced system reliability. This capability not only improves efficiency but also prolongs the lifespan of equipment, further contributing to cost savings. Additionally, their modular design allows for easier maintenance and upgrades, meaning businesses can adapt quickly to changing energy needs without incurring significant downtimes.

Tips: To maximize the benefits of BPX heat exchangers, industries should conduct regular performance assessments to identify potential inefficiencies. Implementing a predictive maintenance strategy can also safeguard against unexpected breakdowns, ensuring continuous operation and optimizing overall energy use. Investing in training for staff on the latest technologies can further enhance the operational effectiveness of heat exchanger systems.

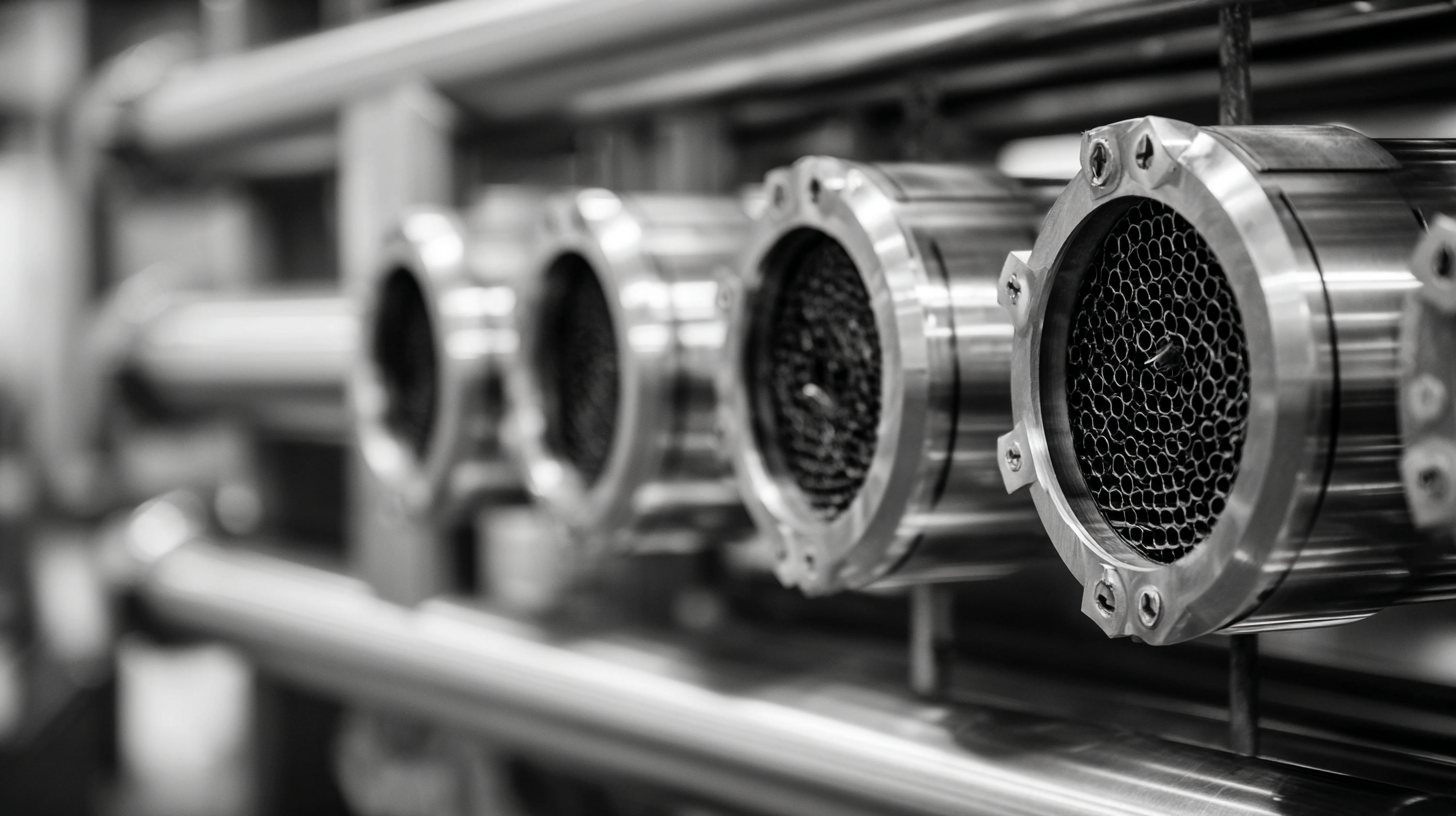

Proper maintenance of Bpx heat exchangers is crucial for ensuring their optimal performance in modern industrial settings. Regular inspections should be conducted to check for signs of fouling or corrosion, which can significantly impact heat transfer efficiency. According to a report by the International Journal of Heat and Mass Transfer, systems that undergo routine maintenance can achieve up to 20% greater thermal efficiency compared to those that are neglected. Cleaning techniques, such as chemical cleaning or high-pressure water jetting, should be employed based on the specific type of fouling encountered.

In addition, monitoring operational parameters like pressure drop and temperature differentials can provide valuable insights into the condition of the heat exchangers. The Heat Exchange Institute suggests that maintaining a consistent temperature differential within the optimal range can prolong the lifespan of Bpx units, reducing the risk of unexpected failures. Leveraging advanced diagnostic tools, such as thermography or ultrasonic testing, can further enhance maintenance efforts by allowing for early detection of potential issues before they escalate, thus safeguarding the overall reliability of industrial processes.

The future of heat exchanger technology is poised for significant advancements, driven by the increasing demand for energy efficiency and sustainability across various industries. As industries strive to minimize their carbon footprints and optimize thermal management systems, innovations in heat exchanger design and material selection are likely to play a pivotal role.

Emerging trends include the integration of advanced materials that enhance thermal conductivity, as well as the application of nanotechnology to improve heat transfer efficiency.

Moreover, the shift towards renewable energy sources is likely to spur the development of heat exchangers that can operate effectively under diverse and variable conditions. For instance, in the data center sector, innovative cooling solutions that utilize heat exchangers will be critical in addressing the escalating energy demands due to data processing and storage.

As these systems evolve, the focus will be on creating more compact, reliable, and efficient heat exchangers that can seamlessly incorporate into existing infrastructures while maintaining optimal performance.

With the market for energy-efficient technologies expected to grow steadily, the role of heat exchangers will be increasingly pivotal in shaping the industrial landscape of the future.