Leave Your Message

In the realm of modern industrial applications, the efficiency of thermal management systems is paramount. The Bpx Heat Exchanger stands out as a game-changer in this domain, offering enhanced heat transfer capabilities and energy savings that align perfectly with the demands of contemporary industries. According to a recent report by the International Institute of Refrigeration, effective heat exchanger technologies can lead to energy efficiency improvements of up to 30%, significantly reducing operational costs and environmental impact.

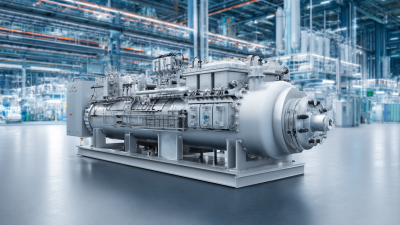

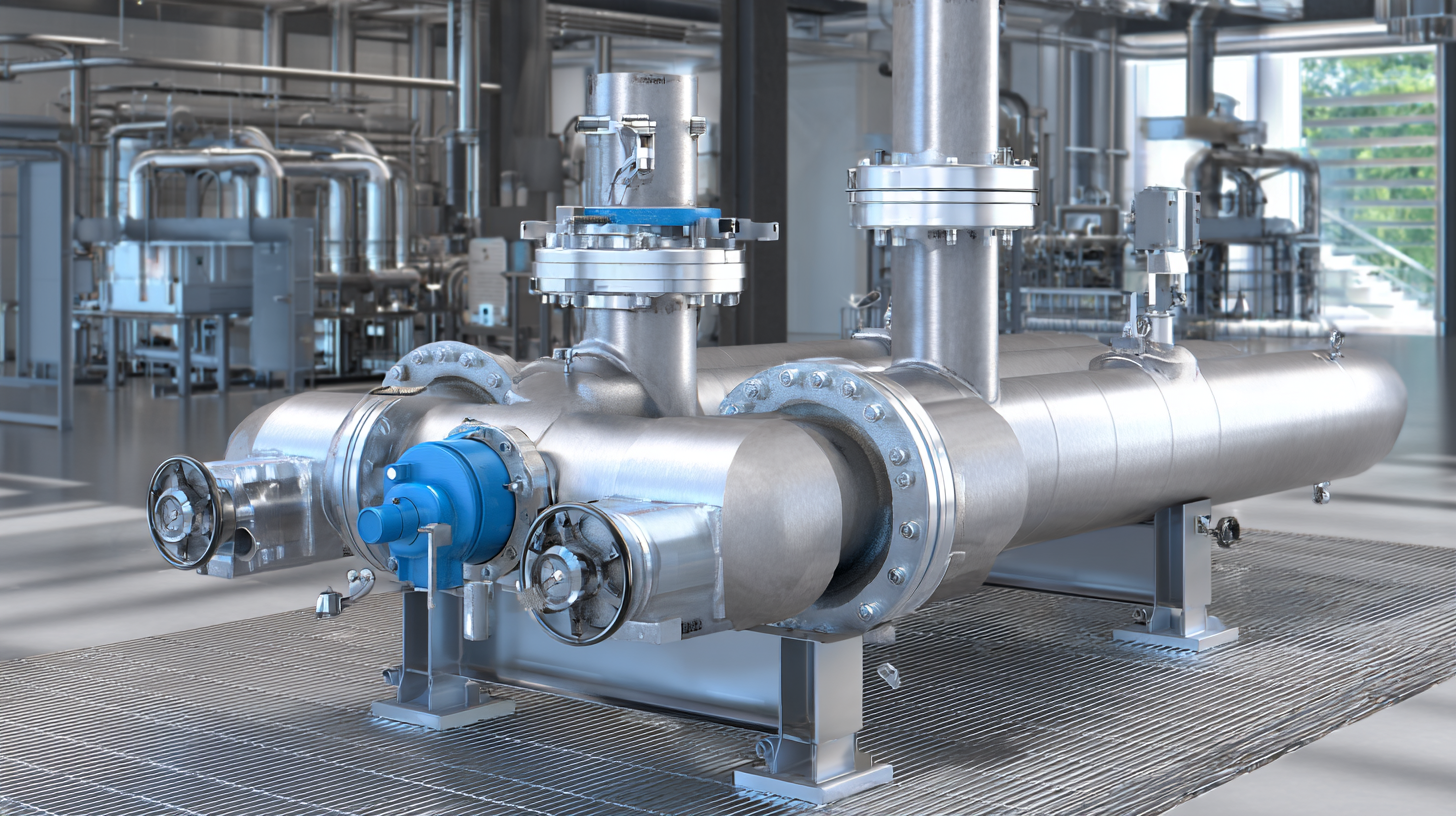

Additionally, the Bpx Heat Exchanger's innovative design facilitates a compact footprint while maximizing thermal performance, making it an ideal solution for sectors such as chemical processing, power generation, and food manufacturing. As industries strive to meet stringent regulatory standards and sustainability goals, the adoption of advanced technologies like the Bpx Heat Exchanger proves crucial in achieving operational excellence and environmental stewardship.

Heat exchangers play a crucial role in enhancing industrial efficiency by facilitating effective thermal energy transfer between different fluids. According to a report by the International Energy Agency (IEA), heat exchangers account for approximately 40% of the total energy used in industrial processes. This significant percentage highlights their importance in reducing energy consumption and operational costs. By optimizing heat recovery systems, industries can improve their overall productivity while adhering to sustainability goals, as energy-efficient operations substantially lower greenhouse gas emissions.

The use of BPX heat exchangers, in particular, is becoming increasingly prevalent due to their advanced design and superior performance capabilities. A study conducted by TechNavio indicated that the global heat exchanger market is projected to grow at a CAGR of over 6% from 2021 to 2025, driven largely by the adoption of energy-efficient technologies across various sectors. Industries such as chemical processing, oil and gas, and power generation are reaping the benefits of enhanced heat dissipation and lower maintenance costs provided by BPX heat exchangers. These systems not only increase thermal efficiency but also support compliance with environmental regulations by utilizing waste heat more effectively.

Bpx heat exchangers have become integral components in modern industrial applications, particularly in enhancing energy conservation strategies. According to a report from the International Energy Agency (IEA), heat exchangers can improve energy efficiency by up to 30%, significantly reducing operational costs and environmental impact. These devices facilitate optimal thermal energy transfer across systems, minimizing thermal losses which are traditionally a major concern in industrial processes.

In addition to their efficiency, Bpx heat exchangers are recognized for their versatility across various sectors. A study published by the U.S. Department of Energy revealed that implementing advanced heat exchanger technologies could lead to energy savings of approximately 4.9 quadrillion BTUs annually across the industrial sector. This substantial figure underscores the critical role these systems play not only in energy conservation but also in promoting sustainability. Companies adopting Bpx heat exchangers have reported enhanced temperature control and lower emissions, further solidifying their importance in the move toward greener industrial practices.

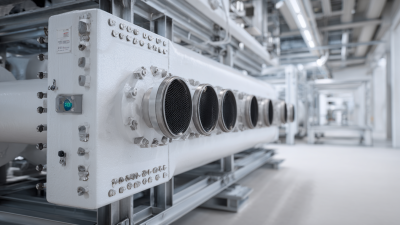

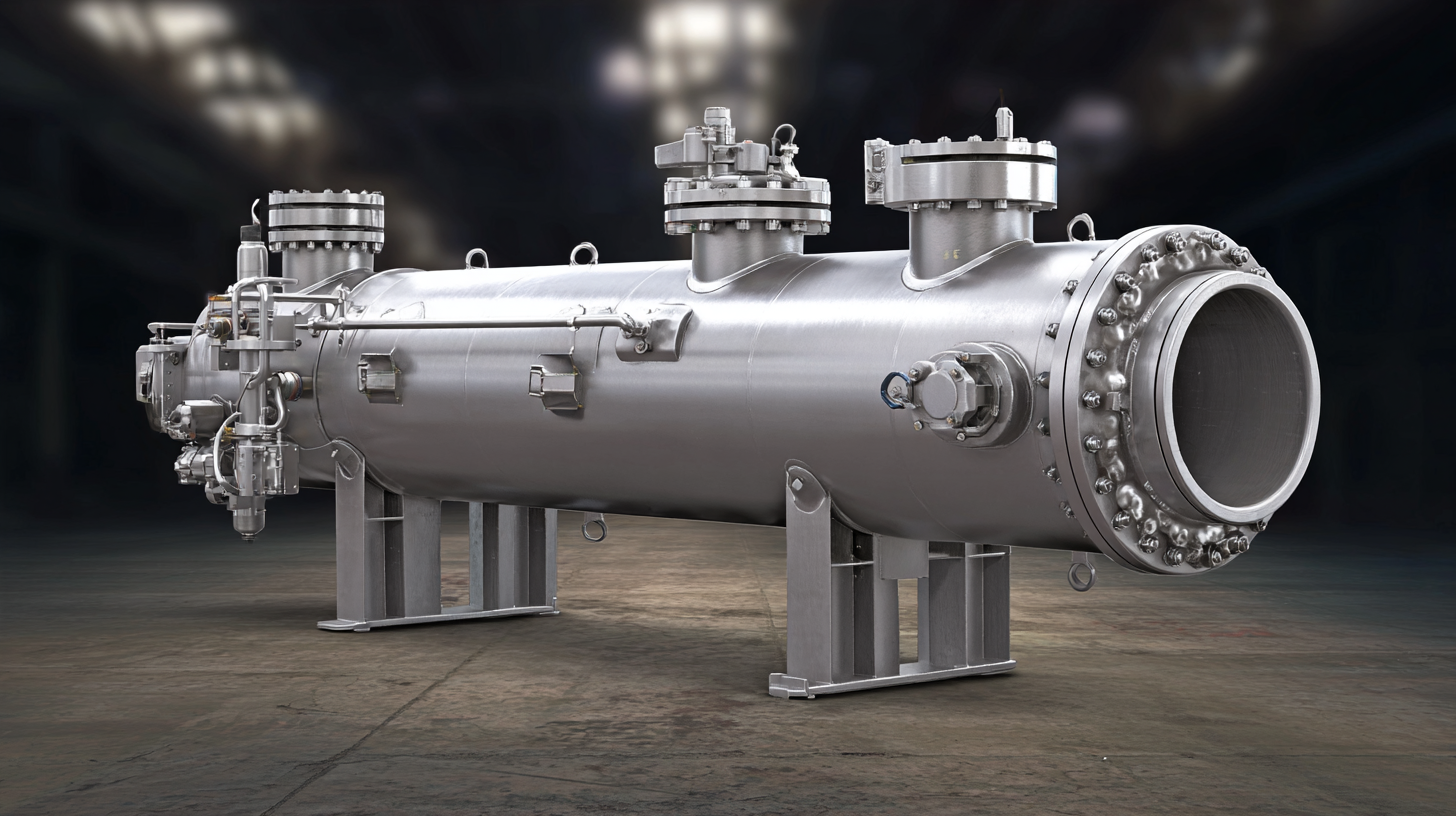

In modern industrial applications, Bpx heat exchangers play a vital role in enhancing process safety and reliability. Their design facilitates efficient heat transfer between fluids, thereby minimizing the risk of overheating and equipment failure. By maintaining optimal operating temperatures, these heat exchangers significantly reduce the likelihood of hazardous incidents, ensuring a safer working environment for personnel and safeguarding equipment integrity.

The recent developments in process engineering, highlighted at events like ACHEMA 2022, demonstrate the growing emphasis on advanced heat exchanger technologies. These innovations not only improve energy efficiency but also contribute to sustainable industrial practices. The integration of state-of-the-art heat exchangers is crucial for industries looking to enhance operational reliability and meet stringent safety standards, further solidifying their importance in today’s competitive market. As demonstrated in recent initiatives, the ongoing refinement of heat exchanger technology underscores its essential role in modern industrial processes.

| Dimension | Measurement | Benefit |

|---|---|---|

| Heat Exchange Efficiency | >90% | Improved energy savings and reduced operational costs. |

| Material Durability | 10-15 years | Enhances overall reliability and reduces maintenance needs. |

| Operating Temperature Range | -50°C to 350°C | Versatile application in various industries. |

| Footprint | Compact Design | Saves space and allows flexible installations. |

| Logistic Support | Global Network | Swift delivery and reliable support services. |

| Safety Features | Dual Safety Mechanisms | Enhances process safety and operational reliability. |

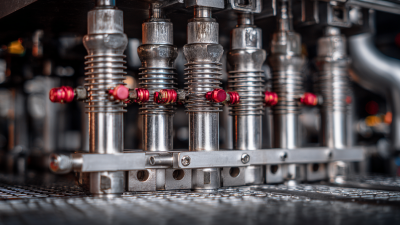

When comparing Bpx heat exchangers to traditional options, it’s essential to consider several key advantages that Bpx technology brings to modern industries. Unlike conventional heat exchangers, which often suffer from inefficiencies due to fouling and maintenance challenges, Bpx heat exchangers are designed with advanced materials and innovative designs that minimize these issues. Their greater durability means they require less frequent maintenance, leading to increased operational uptime and reduced costs over time.

Moreover, the efficiency of Bpx heat exchangers is notable. They leverage enhanced heat transfer capabilities, allowing for better thermal performance while occupying less space. This compact design is particularly advantageous in industries where space is at a premium. Additionally, Bpx units often feature improved energy conservation, lowering operational costs while meeting environmental regulations. By reducing energy consumption, these heat exchangers not only help companies save money but also contribute to sustainability efforts within the industrial sector.

BPX heat exchangers play a crucial role in promoting sustainable industrial practices by enhancing energy efficiency and reducing environmental impact. These advanced systems are designed to optimize heat recovery processes, allowing industries to reuse thermal energy that would otherwise be wasted. This not only lowers energy consumption but also diminishes greenhouse gas emissions, aligning industrial operations with global sustainability goals.

Moreover, the use of BPX heat exchangers contributes to resource conservation. By facilitating effective temperature regulation and minimizing material waste, these exchangers enable industries to operate more effectively while adhering to stringent environmental regulations. The ability to integrate with renewable energy sources further elevates their significance, making them essential in the transition towards greener industrial practices.

As industries strive for greater sustainability, BPX heat exchangers are proving to be indispensable tools in achieving a balance between operational efficiency and ecological responsibility.