Leave Your Message

In the rapidly evolving landscape of modern industries, the efficiency of thermal management plays a crucial role in enhancing productivity and sustainability. One pivotal technology that has garnered attention is Plate Heat Transfer, which utilizes a series of plates to facilitate efficient heat exchange between fluids. This innovative approach not only maximizes heat transfer rates but also minimizes energy consumption and water use, making it an environmentally friendly option. The versatility of Plate Heat Transfer technology enables its application across various sectors, from food processing and HVAC systems to chemical processing and renewable energy systems.

In the rapidly evolving landscape of modern industries, the efficiency of thermal management plays a crucial role in enhancing productivity and sustainability. One pivotal technology that has garnered attention is Plate Heat Transfer, which utilizes a series of plates to facilitate efficient heat exchange between fluids. This innovative approach not only maximizes heat transfer rates but also minimizes energy consumption and water use, making it an environmentally friendly option. The versatility of Plate Heat Transfer technology enables its application across various sectors, from food processing and HVAC systems to chemical processing and renewable energy systems.

As industries increasingly prioritize energy efficiency and ecological sustainability, understanding the benefits and practical applications of Plate Heat Transfer technology becomes essential for thriving in today’s competitive market. This exploration will delve into the significant advantages offered by this method, highlighting its role in shaping the future of thermal management in diverse industrial settings.

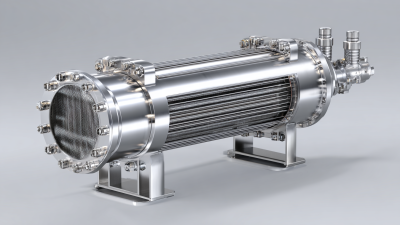

Plate heat transfer technology has gained significant traction in various modern industries due to its efficient heat exchange mechanisms. This technology employs thin, corrugated plates which provide a larger surface area for heat transfer compared to traditional heat exchangers, resulting in enhanced thermal performance. According to a report from the International Energy Agency, plate heat exchangers (PHEs) can achieve thermal efficiency levels exceeding 90%, making them particularly advantageous in industries like chemical processing, food production, and HVAC systems.

The mechanisms behind plate heat transfer involve the principles of conduction and convection. When fluids pass through the narrow channels formed by the plates, turbulent flow increases the heat transfer surface area, promoting quicker temperature equalization. Research from the American Society of Heating, Refrigerating and Air-Conditioning Engineers noted that PHEs can reduce operational energy consumption by 20-30% compared to traditional shell-and-tube designs. This efficiency not only leads to lower energy costs but also supports sustainability efforts by optimizing resource use in industrial applications. As industries strive for improved energy efficiency and lower carbon footprints, the adoption of plate heat transfer technology continues to rise.

| Application | Benefit | Industry | Efficiency Improvement (%) | Heat Recovery Potential (kW) |

|---|---|---|---|---|

| Food Processing | Reduced energy costs | Food & Beverage | 20% | 500 |

| Chemical Processing | Enhanced thermal efficiency | Chemicals | 15% | 800 |

| HVAC Systems | Improved cooling performance | Building Services | 25% | 300 |

| Pharmaceutical Production | Better process control | Pharmaceuticals | 18% | 400 |

| Renewable Energy | Maximized heat transfer | Energy | 30% | 1000 |

Plate heat exchangers (PHEs) have emerged as a pivotal technology across various industries, primarily due to their superior thermal efficiency and compact design. According to a report by Transparency Market Research, the global plate heat exchanger market is anticipated to reach USD 3.2 billion by 2027, growing at a CAGR of 8.5% from 2020. This growth is significantly driven by the food and beverage sector, which requires precise temperature control and sanitation. The capabilities of PHEs to handle both high pressures and varying flow rates make them ideal for pasteurization processes and refrigeration applications.

In the chemical and petrochemical industries, plate heat exchangers provide significant benefits in energy recovery and process optimization. A study by Research and Markets suggests that by implementing PHE technology, companies can reduce energy consumption by approximately 30%. Moreover, their modular design allows for easy maintenance and upgrades, minimizing downtime and enhancing productivity. This adaptability positions plate heat exchangers as a vital component in modernizing industrial processes, aligning with the increasing demands for sustainability and efficiency in today's energy-conscious market.

Plate heat transfer technology has found extensive applications across various industries, showcasing its versatility and efficiency. In the food and beverage sector, for instance, plate heat exchangers are essential for pasteurization processes, allowing for rapid heating and cooling of liquids while minimizing energy consumption. This technology not only ensures food safety but also helps maintain product quality, which is crucial in an industry where freshness is paramount.

Another significant application can be seen in the chemical processing industry. Plate heat exchangers facilitate efficient temperature control during exothermic and endothermic reactions, allowing for more precise management of chemical processes. Their compact design makes them particularly advantageous in facilities with limited space, enabling higher heat transfer rates in a smaller footprint. Additionally, the ability to disassemble plate heat exchangers for cleaning and maintenance contributes to enhanced operational efficiency and longevity, making them a preferred choice for many modern industrial applications.

In recent years, the industrial sector has seen a significant shift towards utilizing plate heat exchangers (PHEs) over traditional heat transfer methods like shell-and-tube exchangers. According to a market research report by Technavio, the global plate heat exchangers market is projected to reach USD 7.13 billion by 2025, growing at a CAGR of 6.5%. This growth is driven by the PHEs' superior efficiency, compact size, and reduced maintenance costs compared to conventional systems.

One of the most notable advantages of plate heat exchangers is their enhanced thermal performance. They offer higher heat transfer coefficients due to their increased surface area and the turbulent flow created by plates. A study published in the International Journal of Thermal Sciences indicated that PHEs can achieve thermal efficiency improvements of up to 30% compared to shell-and-tube designs. Additionally, PHEs require less space, making them ideal for plants with constrained layouts. The ability to clean and maintain these exchangers without extensive downtime further positions them as the preferred choice in industries such as food processing, pharmaceuticals, and HVAC.

The future of plate heat transfer technology is bright, driven by ongoing innovations and increasing demand for energy efficiency across various industries. Recent reports indicate that the global heat exchanger market, valued at approximately $15.8 billion in 2021, is projected to reach $23 billion by 2028, highlighting a robust growth driven in part by advancements in plate heat exchanger designs. Manufacturers are now focusing on compact and lightweight constructions that not only enhance thermal performance but also facilitate easier installation and maintenance.

One of the key trends in plate heat transfer technology is the integration of smart features. With the rise of Industry 4.0, the incorporation of IoT technology into heat exchangers allows for real-time monitoring and predictive maintenance, reducing downtime and optimizing operational efficiency. According to a report by Grand View Research, the demand for smart heat exchangers is anticipated to grow significantly, with an estimated CAGR of over 7% from 2022 to 2030. This integration not only enhances the overall performance but also contributes to sustainability goals, as companies aim to lower their carbon footprint through improved energy management systems.