Leave Your Message

In the rapidly evolving landscape of industrial technology, 2025 is set to bring transformative changes to heat exchanger maintenance practices. As industries increasingly focus on optimizing efficiency and reducing operational costs, understanding the top trends in heat exchanger maintenance becomes essential. Industry expert Dr. Julia Thompson, a leading authority in thermal systems management, emphasizes the significance of proactive maintenance strategies by stating, "The future of heat exchanger maintenance lies not just in repair, but in predictive analytics and real-time monitoring."

As we anticipate the challenges and opportunities of 2025, an emphasis on data-driven approaches is evident. The integration of digital solutions with traditional maintenance practices promises not only to enhance the lifespan of heat exchangers but also to maximize their performance. Companies will need to adapt to these innovations to stay competitive, ensuring that their maintenance operations are not just reactive, but strategic.

With the focus on sustainability and operational excellence, the industry is poised for a revolution in heat exchanger maintenance. This outline will delve into the most impactful trends that practitioners and enterprises should be aware of to successfully navigate the complexities of maintaining these vital components in industrial processes. Embracing these trends will not only ensure compliance with regulations but also contribute to a more sustainable and efficient operational future.

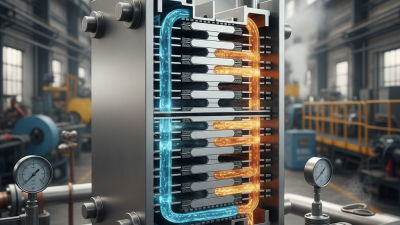

Emerging technologies in heat exchanger monitoring and maintenance are transforming the industry, paving the way for enhanced efficiency and reduced operational costs. According to a recent report by MarketsandMarkets, the global heat exchanger market is expected to reach $23.5 billion by 2025, driven by increasing demand for energy-efficient solutions in various sectors. One of the most impactful advancements is the integration of Internet of Things (IoT) sensors in monitoring systems, which facilitate real-time data collection and analysis. This technology allows operators to track crucial performance metrics and identify potential issues before they escalate, thereby minimizing downtime.

Moreover, predictive maintenance strategies leveraging artificial intelligence (AI) are becoming increasingly prevalent. By analyzing historical data alongside real-time performance indicators, AI algorithms can predict potential failures with remarkable accuracy. A study by Deloitte highlights that predictive maintenance can reduce maintenance costs by up to 30% and can increase equipment uptime by 25%. As heat exchanger systems become more complex, these technological innovations will play a critical role in ensuring their reliable operation, ultimately leading to more sustainable industrial practices.

Predictive maintenance is revolutionizing the approach to heat exchanger care, enabling facilities to enhance the longevity and efficiency of these critical systems. By employing advanced data analytics and real-time monitoring technologies, operators can identify potential issues before they become major problems. This proactive strategy allows for timely interventions, reducing both the frequency and severity of unexpected breakdowns. For instance, sensors integrated into heat exchangers can track temperature anomalies, pressure variations, and fluid flow rates, providing a comprehensive view of performance metrics.

Furthermore, predictive maintenance aligns with the principles of Industry 4.0, as it leverages machine learning algorithms to analyze historical data and forecast future maintenance needs. This ensures that maintenance schedules are optimized, minimizing downtime and extending the operational life of heat exchangers.

As organizations increasingly adopt these technologies, not only do they reduce operating costs, but they also contribute to a more sustainable and efficient industrial environment. By embracing these innovative maintenance strategies, companies can ensure their heat exchangers are running at peak performance, providing reliable service while optimizing resource utilization.

The focus on sustainable practices in heat exchanger cleaning and repair is becoming increasingly vital as industries strive to reduce their environmental impact. According to a report by the Global Heat Exchanger Market, nearly 30% of the operational costs in energy-intensive sectors can be attributed to inefficient heat exchanger maintenance. By adopting eco-friendly cleaning methods, companies can enhance efficiency while minimizing their carbon footprint.

One effective sustainable practice is the use of biodegradable cleaning agents. These agents not only reduce harmful chemical usage but also ensure a safer working environment for maintenance personnel. Additionally, investing in advanced technologies, such as ultrasonic cleaning, can significantly decrease water and energy consumption. A recent study shows that ultrasonic methods can reduce cleaning time by up to 50%, highlighting their effectiveness in improving maintenance efficiency.

Tips: To maximize sustainability, regularly schedule maintenance to prevent extensive cleaning processes. Incorporating heat exchanger optimization techniques can also lead to better energy management, ultimately resulting in reduced downtime and lower operational costs. Engaging with suppliers who prioritize environmentally friendly products will further support your maintenance goals in 2025 and beyond.

The integration of AI and machine learning (ML) in heat exchanger maintenance is set to revolutionize performance optimization by 2025. A recent report from MarketsandMarkets predicts that the global Heat Exchanger market, valued at $15.45 billion in 2020, is anticipated to grow to $20.75 billion by 2025, showcasing the increasing importance of these systems. By harnessing AI and ML, operators can gain predictive insights into heat exchanger behavior, thereby reducing unplanned downtime by up to 30%, as highlighted in a study by McKinsey & Company.

AI algorithms analyze vast amounts of operational data in real-time, identifying patterns and anomalies that human operators might miss. For instance, AI-driven predictive maintenance models can forecast potential failures with an accuracy rate of 85%, significantly mitigating the risks associated with manual inspections. Additionally, a report from the International Journal of Heat and Mass Transfer details that advanced machine learning techniques can enhance the efficiency of heat transfer processes, increasing overall system effectiveness by approximately 15%, which is critical for industries striving for sustainability and reduced energy costs.

In 2025, the heat exchanger maintenance landscape will be significantly influenced by new regulatory changes aimed at enhancing safety and efficiency standards across various industries. As global markets for heat exchangers, such as the plate and frame types, are projected to grow substantially, these changes will focus on compliance with environmental regulations, energy efficiency mandates, and safety protocols that ensure optimal performance. Companies will need to adapt their maintenance practices to align with these evolving standards, adopting more rigorous monitoring techniques and technologies to ensure their systems meet the required benchmarks.

Additionally, the emphasis on sustainability and reduced carbon footprints will drive innovation in heat exchanger maintenance. Organizations are expected to invest in advanced predictive maintenance tools and data analytics to anticipate issues before they arise, thus minimizing downtime and maximizing operational efficiency. As the market approaches an estimated value of USD 10.50 billion by 2030, staying abreast of these regulatory shifts will be crucial for stakeholders aiming to leverage growth opportunities while ensuring compliance and operational excellence in heat exchanger maintenance.

| Trend | Description | Impact on Maintenance | Regulatory Change |

|---|---|---|---|

| Digital Monitoring | Utilization of IoT sensors for real-time monitoring of heat exchangers. | Improved predictive maintenance capabilities. | Increased regulations around emissions and performance monitoring. |

| Sustainability Focus | Integration of environmentally friendly materials and practices. | Enhanced efficiency and reduced environmental footprint. | New government incentives for sustainable operations. |

| AI in Maintenance | Artificial intelligence for scheduling and predictive analysis. | Reduced downtime through intelligent scheduling. | Compliance requirements for risk management and safety protocols. |

| Thermal Performance Testing | More rigorous standards for thermal performance assessments. | Increased maintenance frequency to meet standards. | Updates in thermal efficiency regulations for industrial systems. |