Leave Your Message

In the realm of advanced manufacturing and chemical processing, the efficiency and effectiveness of Phe Exchangers are paramount for optimizing production yields. The importance of these critical components cannot be overstated, as they play a vital role in heat transfer and material exchange across various industries. As industry expert Dr. Emily Chen aptly stated, “A well-designed Phe Exchanger not only enhances operational efficiency but also significantly reduces energy costs.” This insight underscores the need for adherence to the latest best practices and guidelines in the design and maintenance of Phe Exchangers.

As we approach the year 2025, it becomes essential for engineers and plant managers to stay abreast of the evolving standards that dictate optimal usage of Phe Exchangers. With advancements in technology and a growing emphasis on sustainability, the guidelines we outline in this article are geared towards helping professionals harness the full potential of their Phe Exchangers. By integrating innovative solutions and embracing systematic approaches, industries can achieve not just compliance, but a competitive edge in their operations.

This discussion will cover critical factors such as design considerations, maintenance protocols, and efficiency benchmarks that are crucial for maximizing the performance of Phe Exchangers. Together, these guidelines will pave the way for enhanced productivity and environmental responsibility in the ever-evolving landscape of industrial processes.

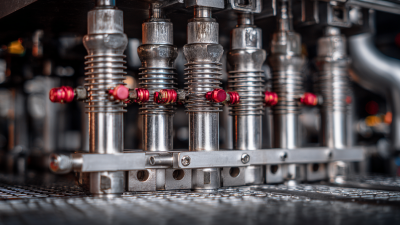

Phe exchangers play a crucial role in various industrial processes, particularly in chemical manufacturing and water treatment systems. As we approach 2025, the need for optimized efficiency in their usage becomes increasingly evident. Phe exchangers facilitate heat transfer between two fluids, allowing for energy recovery and enhanced process efficiency. Their ability to maintain temperature control is vital for maximizing productivity while minimizing energy consumption, making them indispensable in sustainable operations.

In 2025, the emphasis on environmental sustainability and energy efficiency will heighten the significance of phe exchangers. Industries will likely adopt advanced technologies that enhance the performance of these systems, ensuring they meet stringent regulatory requirements and operational efficiency targets. The implementation of smart sensors and advanced control systems can optimize the operation of phe exchangers, allowing for real-time adjustments that respond to varying process conditions. This progressive approach not only conserves resources but also reduces operational costs, making phe exchangers a vital asset for forward-thinking businesses focused on sustainability and long-term viability.

This chart showcases the efficiency of various types of Phe exchangers in 2025, highlighting their heat transfer coefficients and flow rates. The data reflects current performance metrics essential for optimal usage in industrial applications.

The efficiency of plate heat exchangers (PHEs) is heavily influenced by several key factors, which are crucial for maximizing their performance in industrial applications. One of the most significant determinants is the flow arrangement, including counterflow and parallel flow configurations. Reports indicate that counterflow designs can enhance the thermal efficiency by up to 50% compared to parallel flow setups, leading to reduced energy consumption and operational costs. Additionally, the optimal channel design and plate spacing play critical roles; narrower channels can increase turbulence, thereby improving heat transfer rates, but may also lead to higher pressure drop issues if not properly optimized.

Another essential factor is the operating temperatures and pressures. A study by the International Energy Agency (IEA) highlights that operating PHEs at higher temperatures can improve thermal efficiency, but it must be balanced with material limitations and the potential for fouling. The maintenance practices adopted, particularly the frequency of cleaning and monitoring for fouling, also significantly affect the overall efficiency. Regular maintenance schedules can enhance performance by more than 30%, mitigating downtime and extending the equipment's lifespan. Overall, understanding and optimizing these factors are vital for achieving the best efficiency and usage from PHEs in various industrial processes.

| Efficiency Factor | Optimal Value | Impact on Performance (%) | Maintenance Frequency (Months) | Common Issues |

|---|---|---|---|---|

| Heat Transfer Efficiency | 90% - 95% | 25% | 6 | Fouling, Corrosion |

| Pressure Drop | < 0.5 bar | 20% | 12 | Blockage, Wear |

| Material Compatibility | Stainless Steel | 15% | 24 | Leaking, Durability Issues |

| Flow Rate | Optimal Range | 30% | 3 | Inefficiency, Noise |

| Temperature Regulation | 45°C - 60°C | 10% | 6 | Overheating, Efficiency Loss |

To optimize the usage of Phe exchangers, several best practices should be adhered to in order to enhance their efficiency and longevity. First and foremost, it is essential to regularly monitor the operating conditions of the exchanger, including temperature, pressure, and flow rates. Deviations from the optimal parameters can lead to decreased performance and potential damage. Implementing a routine maintenance schedule, which includes cleaning and inspecting the internal surfaces, can significantly prolong the life of the equipment.

Additionally, proper fluid selection is crucial for optimal exchanger performance. Utilizing fluids that are compatible with the materials of the exchanger can prevent corrosion and fouling, which can severely affect heat transfer efficiency. It is advisable to also consider the flow configuration; for instance, counterflow arrangements often yield better performance by providing a greater temperature difference between the two fluids. Training staff on the correct operational procedures and the significance of monitoring these variables is vital to ensure continuous optimal performance of the Phe exchangers.

Proper maintenance and troubleshooting of plate heat exchangers (PHE) are essential for ensuring optimal performance and longevity. Regular inspection is crucial; operators should check for signs of wear, fouling, or corrosion. Visual inspections can help identify buildup on the plates, which can significantly impact heat transfer efficiency. Cleaning schedules should be established based on the system's operational demands and the type of fluids being processed. Using appropriate cleaning methods, such as chemical cleaning or mechanical brushing, is vital to remove deposits without damaging the plates.

Troubleshooting common issues in PHE systems involves a systematic approach. If the heat exchanger shows reduced output efficiency, operators should first check the flow rates and ensure they align with design specifications. Pressure drops can indicate blockages or leaks; therefore, monitoring pressure gauges is crucial. Additionally, if unexpected temperature deviations occur, it is essential to verify the inlet and outlet temperatures and inspect for potential refrigerant or fluid leaks. By remaining vigilant and proactive in maintenance and troubleshooting, operators can enhance the efficiency of their PHE systems, ultimately leading to improved operational reliability and cost savings.

The landscape of Phe exchanger technology is rapidly evolving, driven by innovations aimed at enhancing efficiency and sustainability. Current trends highlight an increasing focus on energy recovery systems integrated into Phe exchangers. According to a recent report by the International Energy Agency, implementing advanced heat exchangers can lead to efficiency gains of up to 25%, optimizing energy consumption in various industrial applications.

Moreover, the future of Phe exchangers is likely to be shaped by the advancement of materials capable of withstanding higher temperatures and corrosive environments. Researchers are investigating the use of composite materials that provide better thermal conductivity while reducing weight. A study published in the Journal of Advanced Materials indicates that these next-generation materials could reduce operational costs and extend the lifespan of heat exchangers, making them a viable choice for industries facing stringent emission regulations.

**Tips:** When selecting a Phe exchanger, consider the specific thermal performance requirements and corrosion resistance of materials relevant to your application. Regular maintenance can further enhance the longevity and efficiency of your equipment. Investing in smart monitoring systems can also offer real-time adjustments, significantly improving overall operational efficiency.