Leave Your Message

In the ever-evolving landscape of energy efficiency, the Gasketed Plate Heat Exchanger (GPHE) stands out as a critical component in various industrial applications. As industries face increasing pressure to reduce energy consumption and improve thermal management, insights into cutting-edge technologies become indispensable. According to Dr. Emily Carter, a renowned expert in thermal engineering, “The advancement of Gasketed Plate Heat Exchangers is pivotal in achieving higher energy savings while maintaining thermal efficiency.”

As we look ahead to the year 2025, it is essential to explore the innovative trends and applications of GPHEs that promise to revolutionize energy usage across various sectors. This exploration not only sheds light on the technical enhancements that drive performance but also emphasizes the importance of sustainable practices. With the integration of smart monitoring systems and advanced materials, the potential of Gasketed Plate Heat Exchangers is set to redefine standards in thermal efficiency, paving the way for significant energy savings.

The following insights will delve into the latest developments and expert opinions surrounding GPHE technology, offering a comprehensive view of its future trajectory and the implications for energy management in the coming years. By harnessing these insights, industries can better position themselves to meet the challenges of energy conservation.

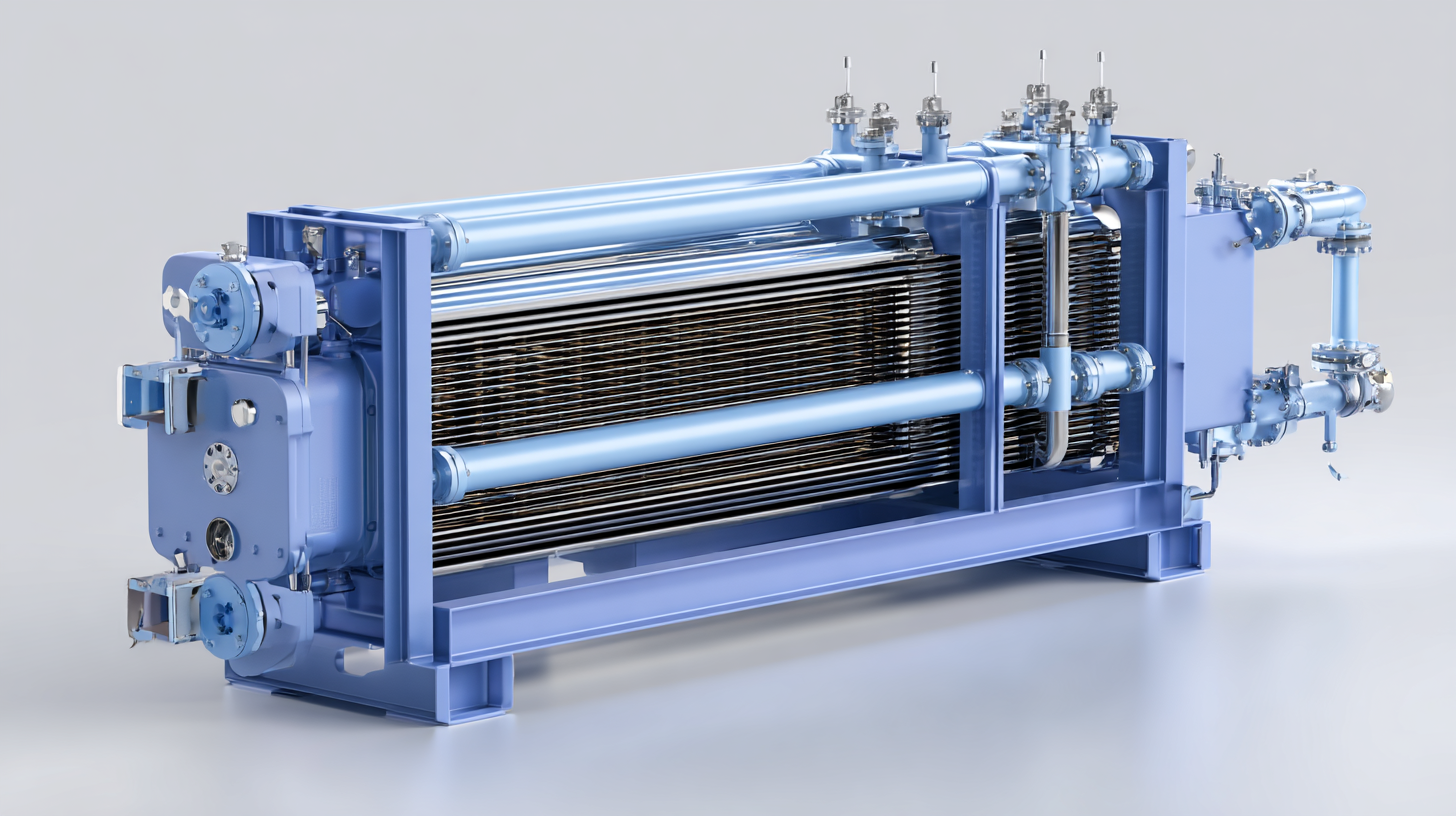

Gasketed plate heat exchangers are vital components in various industries, particularly in food and beverage processing, where they enhance thermal efficiency and facilitate energy savings. Understanding their fundamentals can help manufacturers optimize performance while minimizing operational costs. These heat exchangers operate by having multiple plates that create channels for hot and cold fluids to flow in close proximity, allowing for efficient heat transfer. According to a recent industry report, effective implementation of gasketed plate heat exchangers can lead to energy savings of up to 30% compared to traditional heat exchange methods.

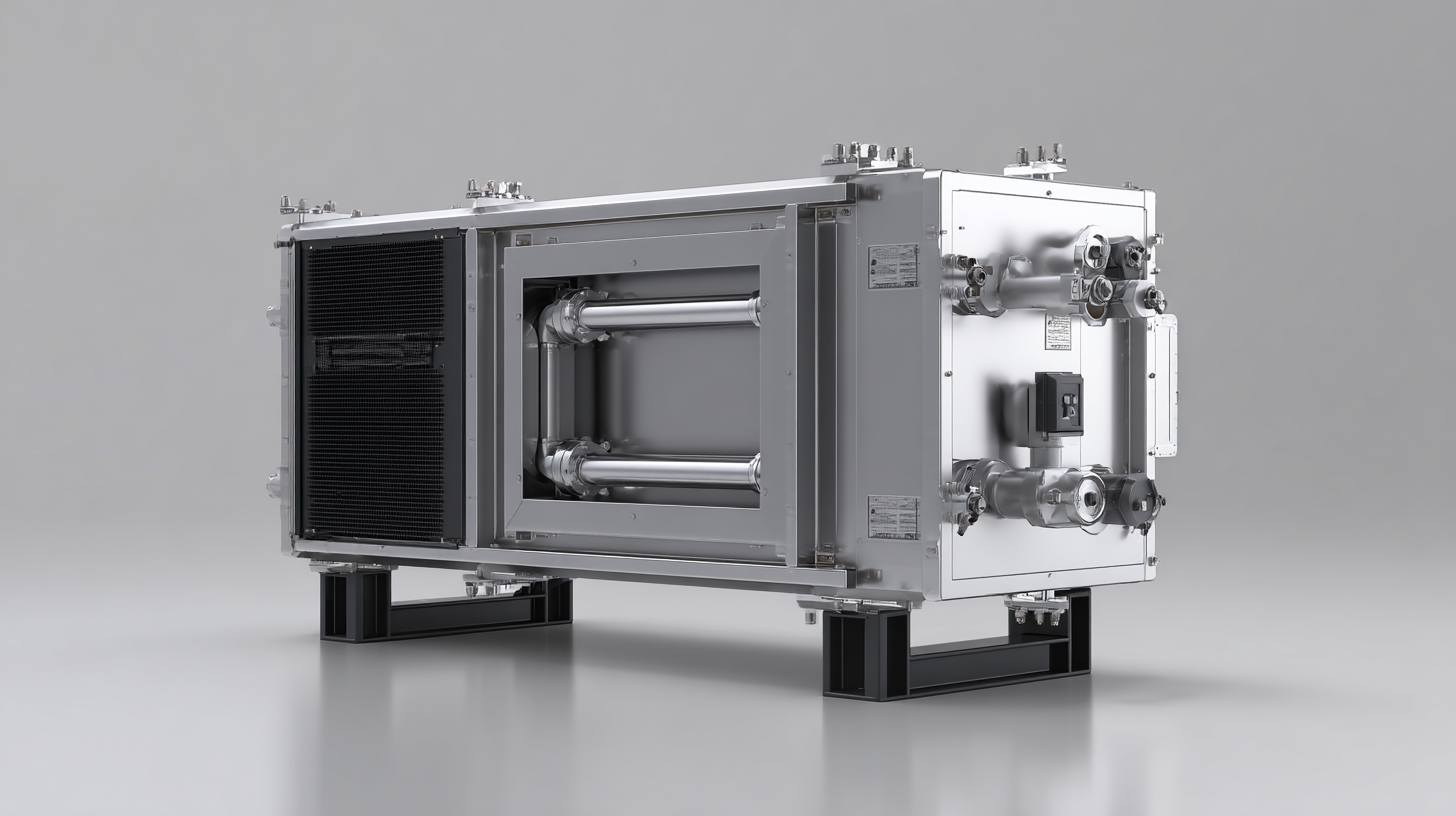

However, as highlighted in recent discussions within the industry, the hidden costs associated with maintenance and repairs of plate heat exchangers can significantly impact overall profitability. The high frequency of repairs, often due to gasket failures, has been a source of concern for manufacturers. Data suggests that downtime from heat exchanger failures can cost companies thousands of dollars daily, emphasizing the importance of selecting durable materials and reliable designs. By focusing on the underlying principles governing gasketed plate heat exchangers and proactively addressing maintenance issues, manufacturers can not only enhance thermal efficiency but also achieve significant long-term savings.

The design features of gasketed plate heat exchangers (GPHEs) play a pivotal role in enhancing thermal efficiency and achieving energy savings. One of the key factors is the plate configuration, which can significantly increase surface area while minimizing fluid resistance. According to a recent industry report by the International Institute of Refrigeration, optimizing the plate pattern can improve heat transfer efficiency by up to 30%, resulting in reduced energy consumption and operational costs.

Additionally, the use of advanced gasket materials contributes to improved thermal performance and longevity. Modern gasket technologies, like high-performance elastomers, offer better resistance to extreme temperatures and aggressive media, increasing operational reliability. A study from the American Society of Mechanical Engineers indicated that utilizing enhanced gaskets can extend service life by more than 20%, thereby decreasing maintenance frequency and associated downtimes in industrial applications.

Moreover, the option to implement variable flow patterns allows for tailored solutions that can adapt to specific process requirements. Incorporating features such as adjustable port sizes can further optimize the flow rate, ensuring that the heat exchanger operates at peak efficiency under varying load conditions. This flexibility is crucial for industries aiming to adopt sustainable practices while maintaining optimal production efficiency.

In the quest for enhanced thermal efficiency and energy savings, operating gasketed plate heat exchangers effectively is paramount. These devices play a crucial role in various industries, particularly in dairy processing, where managing temperature fluctuations is essential for product quality. According to the latest industry reports, optimizing the operation of gasketed plate heat exchangers can lead to significant energy savings, with some facilities reporting reductions of up to 30%–50% in energy consumption through strategic upgrades.

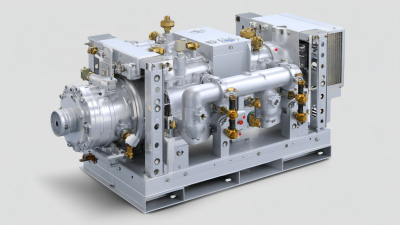

Best practices include regular maintenance, which ensures that these heat exchangers operate at peak efficiency, minimizing energy waste. Additionally, employing advanced technologies like enhanced vacuum pump systems and precision scroll compressors can further streamline operations. By carefully monitoring the thermal performance and making data-driven adjustments, dairy producers can capitalize on the inherent benefits of these systems, reinforcing their role as vital components in energy conservation efforts within the industry.

To ensure optimal performance of gasketed plate heat exchangers, implementing effective maintenance strategies is crucial. Regular inspections are essential for identifying wear and tear, especially in gaskets, which play a pivotal role in preventing leaks. Additionally, monitoring the temperature and pressure of the fluids passing through the exchanger helps in maintaining efficient operation and can highlight any anomalies early on.

**Tips: Adjusting Cleaning Intervals**

Schedule cleaning based on the fouling rates observed in different operations. Frequent cleaning during peak operational seasons can enhance thermal efficiency, while extending intervals during lower usage periods can save time and resources.

Training staff on best practices for handling these units can significantly reduce the risk of operational issues. Proper training includes understanding the importance of maintaining gasket integrity and knowing the correct procedures for replacing gaskets without damaging the plates. This not only prolongs the life of the heat exchanger but also ensures that energy savings are maximized through enhanced thermal efficiency.

**Tips: Documenting Maintenance Activities**

Keep meticulous records of all maintenance procedures, including cleaning, inspections, and repairs. This documentation will help in identifying trends over time, allowing for proactive interventions and continuous improvements in the management of heat exchanger performance.

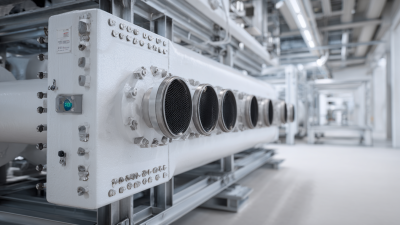

Emerging technologies are radically transforming the landscape of heat exchange systems, particularly through innovative approaches in thermal energy systems (TES). As industries shift toward sustainable practices, the integration of renewable energy sources—ranging from advanced solar and wind systems to AI-driven bioenergy and geothermal solutions—is essential. Recent forecasts indicate that the Heat Transfer Fluids Market is experiencing steady growth, driven by the demand for efficient thermal management in industrial applications. This demand is projected to reach $2.5 billion by 2025, highlighting a crucial shift towards adopting technologies that enhance thermal efficiency.

In the realm of HVAC, innovation is paramount for sustainability. AI-driven diagnostics and smart home systems are becoming integral, promoting operational efficiency and reducing energy consumption. Moreover, cold storage facilities are embracing new energy-efficient technologies, responding to the rising costs of energy and evolving regulatory standards. With the sector projected to grow by over 10% annually, investments in these innovative solutions are set to play a critical role in achieving significant energy savings and improving overall operational performance, making the future of thermal efficiency increasingly bright.